Abstract

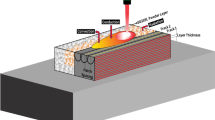

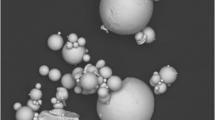

Semi-solid powder forming (SPF) has been widely used to prepare metal matrix composites, during which powder breakage plays an important role in grain refinement and densification process. However, it is not easy to directly observe because of the complicated SPF process, resulting in few investigations. Therefore, based on semisolid compression of AA2024 porous materials, powder breakage behavior and mechanism were studied by introducing the continuity, capillary force, and Newtonian fluid and Roscoe–Einstein model in this work. The results indicate that when the continuity CSS≈1, the powders are not crushed, the liquid solidified as short-rod shapes distributing within a powder is regarded as small holes, and its influence is ignored. When CSS = 0.384–0.608, the powders break up along grain boundaries partially occupied by liquid, with their solid-bonding being torn open, resulting in transgranular ruptures. Its breakage resistance is the combined force acted by the solid-bonding and liquid. When CSS < 0.384, the solid grains are wrapped by liquid with few deformation resistances, regarded as a Newtonian fluid. The breakage resistance of semi-solid powders was calculated by the deduced mathematical equation, and it further confirmed the above results. The breakage coefficient representing the broken degree was calculated and then proved to be consistent with experimental results.

Similar content being viewed by others

References

S. Aghajani, V. Pouyafar, and R. Meshkabadi, P. I. MECH. ENG. E-J PRO 1, 12 (2022).

L.L. Chen, Y.S. Qi, Y.H. Fei, Y.W. Liu, and Z.M. Du, Mater. Tran. 61, 1239 (2020).

L.L. Chen, Y.S. Qi, Y.H. Fei, and Z.M. Du, Met. Mater. Int. 27, 4263 (2021).

X. Luo, S.H. Yang, M.Y. Li, Z.M. Tang, S.L. Wang, B.S. Huang, and T. Indian, I. Metals 74, 12 (2021).

P.B. Li, B. Cao, W.T. Tan, and M.M. Gao, J. Alloy. Compd. 818, 152925 (2020).

P.B. Li, L.Y. Chen, B. Cao, and K.R. Shi, J. Alloy. Compd. 823, 153815 (2020).

A. Javdani, A.H. Daei-Sorkhabi, and T. Nonferr, Metal. Soc. 28, 1298 (2018).

X. Zhang, Y. Wang, T. Chen, H. Xu, and J. Ma, Mater. Sci. Eng. A 838, 142781 (2022).

Z.Q. Mo, Y.Z. Liu, J.J. Geng, and T. Wang, Mater. Sci. Eng. A 652, 305 (2016).

M. Wu, Y.Z. Liu, T. Wang, and K.B. Yu, Mater. Sci. Eng. A 674, 144 (2016).

X. Luo, Y.Z. Liu, C.X. Gu, and Z.L. Li, Powder. Technol. 261, 161 (2014).

X. Luo, M.Y. Li, J. Ren, Y.L. Zhao, M. Wu, and B.S. Huang, JOM 74, 899–908 (2022).

M. Wu, J. Liu, Y.Z. Liu, X. Luo, B. Wang, and C.Y. Du, Mater. Res. Express 8, 066503 (2021).

X. Luo, and Y.Z. Liu, JOM 68, 3078 (2016).

Y.F. Wu, and G.Y. Kim, Powder. Technol. 214, 252 (2011).

Y.F. Wu, and G.Y. Kim, J. Mater. Process. Tech. 216, 484 (2015).

X. Luo, C. Fang, Z. Fan, B.S. Huang, and J. Yang, Mater. Res. Express 6, 076528 (2019).

S. Karagadde, P.D. Lee, B. Cai, J.L. Fife, M.A. Azeem, K.M. Kareh, C. Puncreobutr, D. Tsivoulas, T. Connolley, and R.C. Atwood, Nat. Comm. 6, 8300 (2015).

K. Yuan, and J.F. Wen, Ceram. Int. 4, 28566 (2021).

V. Pejchal, G. Žagar, R. Charvet, C. Dénéréaz, and A. Mortensen, J. Mech. Phys. Solids 99, 70 (2016).

R. Liburkin, D. Portnikov, and H. Kalman, Powder. Technol. 284, 344 (2015).

B.P. Saha, V. Kumar, S.V. Joshi, A. Balakrishnan, and C.L. Martin, Powder. Technol. 224, 90 (2012).

P. Chivavibul, M. Watanabe, S. Kuroda, K. Jin, M. Komatsu, K. Sato, and J. Kitamura, J. Therm. Spray. Techn. 20, 1098 (2011).

B.S. Meher, R. Saha, and D. Chaira, J. Alloy. Compd. 2, 159688 (2021).

R. Li, M.L. Qin, C.C. Liu, Z. Chen, X.L. Wang, and X.H. Qu, Adv. Powder. Technol. 6, 1603 (2017).

C.C. Wang, C.C. Jia, C.C.P. Gao, G.C. Gai, and Y.F. Yang, Rare Met. 34, 183 (2014).

P.B. Li, T.J. Chen, S.Q. Zhang, and R.G. Guan, Metals 5, 547 (2015).

M. Wu, J. Liu, X. Luo, Y.Z. Liu, R.Y. Cai, W. Xu, and X. Chen, Materials Rep. 36, 24 (2021).

M. Wu, Y.Z. Liu, Z.Y.B. Zeng, and W.Y. Luo, JOM 69, 763 (2017).

J. Liu, and R.M. German, Metall. Mater. Trans. A 30, 211 (1999).

M. Wu (Ph.D. Dissertation, South China University of Technology, IA, 2018).

Z.H. Chen and D. Chen (Chemical Industry Press, Beijing, 2012), p.185–235.

X.P. Ren and Y.L. Kang (Metallurgical Industry Press, Beijing, 1998), p.71–83.

S. Shima, and M. Oyane, Int. J. Mech. Sci. 18, 285 (1976).

Y.Z. Liu, X. Luo, and Z.L. Li, J. Mater. Process. Tech. 214, 165 (2014).

H.V. Atkinson, Prog. Mater. Sci. 50, 341 (2005).

L.S. Wu, M. Ek, M.H. Song, and S.C. Du, Steel. Res. Int. 82, 388 (2011).

C.M. Chen, C.C. Yang, and C.G. Chao, J. Mater. Process. Tech. 167, 103 (2005).

M. Wu, B. Wang, X. Luo, M. Liu, Y.K. Wang, J.J. Yu, and Y. Li, Mater. Res. Express 12, 9 (2022).

Acknowledgements

The authors appreciate the financial support from Science and Technology Planning Projects of Guangzhou (202102080110), Sichuan Science and Technology Program (2020YFH0151), Guangdong Province Nature Foundation (2022A1515011065), and Guangdong Polytechnic Normal University talent scientific research launch project (2021SDKYA006).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, M., Liu, J., Luo, X. et al. The Powder Breakage Behavior and Mechanism During Semi-solid Powder Forming. JOM 75, 2511–2524 (2023). https://doi.org/10.1007/s11837-023-05868-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05868-6