Abstract

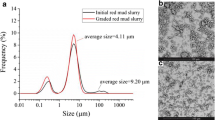

How to obtain an efficient dealkalization process is a key issue for the resource treatment process of red mud. In this work, CaO was added to red mud and then mixed by ball milling after the mixture had been microwave roasted and water leached to achieve efficient dealkalization. The comparative investigation between the conventional roasting and microwave roasting-water leaching process was conducted. After that, the main factors and the mechanism of dealkalization of red mud under microwave roasting conditions were discussed. The results show that microwave roasting has better dealkalization efficiency and less energy consumption than conventional roasting under the same conditions. The dealkalization rate arrived at 84.04% under the optimum conditions, i.e., CaO/SiO2 molar ratio 2.4, microwave power 2.5 kW, roasting temperature 500°C, roasting time 45 min, liquid-solid ratio 8 mL/g, leaching temperature 90°C and leaching time 80 min. Ball milling promoted the mixing degree of red mud and CaO. The microwave roasting could effectively improve the crystal phase transformation of the alkali component in the red mud throughout the roasting process. The alkali metal component in the red mud was significantly extracted. The research can provide an idea for dealkalization and resource utilization of red mud.

Similar content being viewed by others

References

S. Xue, X. Kong, F. Zhu, W. Hartley, and Y. Li, Environ. Sci. Pollut. R. 23, 12822 https://doi.org/10.1007/s11356-016-6478-7 (2016).

F. Lyu, Y. Hu, L. Wang, and W. Sun, J. Hazard. Mater. 403, 123671 https://doi.org/10.1016/j.jhazmat.2020.123671 (2020).

D.Y. Liu, and C.S. Wu, Materials. 5, 1232 https://doi.org/10.3390/ma5071232 (2012).

R. Zhang, S. Zheng, S. Ma, and Y. Zhang, J. Hazard. Mater. 189, 827 https://doi.org/10.1016/j.jhazmat.2011.03.004 (2011).

T. Tian, J. Zhou, F. Zhu, Y. Ye, Y. Guo, W. Hartley, and S. Xue, J. Enviro. Sci. 85, 74 https://doi.org/10.1016/j.jes.2019.05.005 (2019).

B. Jones, R.J. Haynes, and I.R. Phillips, J. Environ. Manage. 95, 29 https://doi.org/10.1016/j.jenvman.2011.09.014 (2012).

B. Das, and K. Mohanty, Renew. Energ. 143B, 1791 https://doi.org/10.1016/j.renene.2019.05.114 (2019).

Y. Wang, T.A. Zhang, G. Lyu, F. Guo, W. Zhang, and Y. Zhang, J. Clean. Prod. 188, 456 https://doi.org/10.1016/j.jclepro.2018.04.009 (2018).

G.L. Zhang, S.C. Li, X.Y. Zhang, and Z.K. Wang, Qingdao Technol. Univ. 33, 59 https://doi.org/10.3969/j.issn.1673-4602.2012.04.013 (2012).

J.Q. Li, Q. Long, and B.J. Xu, Light Met. 11, 11 https://doi.org/10.1016/S1874-8651(10)60095-6 (2009).

G. Hu, F. Lyu, S.A. Khoso, H. Zeng, W. Sun, and H. Tang, Hydrometallurgy 196, 105422 https://doi.org/10.1016/j.hydromet.2020.105422 (2020).

Z. Wang, M.F. Han, Y.H. Zhang, and F.S. Zhou, Bull. Chin. Ceramic Soc. 32, 1851 (2013).

N.W. Menzies, I.M. Fulton, and W.J. Morrell, J. Environ. Qual. 33, 2004 https://doi.org/10.2134/jeq2004.1877 (1877).

Z. Liu, and H. Li, Hydrometallurgy 155, 29 https://doi.org/10.1016/j.hydromet.2015.03.018 (2015).

X. Zhu, W. Li, and X. Guan, J. Hazard Mater. 286, 85 https://doi.org/10.1016/j.jhazmat.2014.12.048 (2015).

F. Zuo, A. Badev, S. Saunier, D. Goeuriot, R. Heuguet, and S. Marinel, J. Eur. Ceram. Soc. 34, 3103 https://doi.org/10.1016/j.jeurceramsoc.2014.04.006 (2014).

S. Galema, Chem. Soc. Rev. 26, 233 (1997).

S.W. Kingman, W. Vorster, and N.A. Rowson, The influence of mineralogy on microwave assisted grinding. Miner. Eng. 13, 313 https://doi.org/10.1016/S0892-6875(00)00010-8 (2000).

R.K. Amankwah, A.U. Khan, C.A. Pickles, and W.T. Yen, Min. Proc. Ext. Met. Rev. 114, 30 https://doi.org/10.1179/037195505X28447 (2005).

A.N. Savenok, Status and prospects of development of metallurgical production in belarus. Litiyo i Metallurgiya (FOUNDRY PRODUCTION AND METALLURGY). 4, 10 (2018).

C. Yang, J. Li, Q. Tan, L. Liu, and Q. Dong, ACS. Sustain. Chem. Eng. 5, 3524 https://doi.org/10.1021/acssuschemeng.7b00245 (2017).

B. Rui, X.L. Wang, D.X. Liu, and Y. Zhang, Powder Technol. 333, 277 https://doi.org/10.1016/j.powtec.2018.04.031 (2018).

W.J. Bruckard, C.M. Calle, R.H. Davidson, A.M. Glenn, S. Jahanshahi, M.A. Somerville, G.J. Sparrow, and L. Zhang, Miner. Process. Extr. Metall. Rev. 119, 18 https://doi.org/10.1179/037195509x12518785461760 (2013).

W. Liu, S. Sun, and L. Zhang, Miner Eng. 39, 213 https://doi.org/10.1016/j.mineng.2012.05.021 (2012).

H.N. Dash, S. Hota, and B.B. Kar, Mater. Today: Proc. 2214, 7853 https://doi.org/10.1016/j.matpr.2021.01.256 (2021).

N. Chandra, S.S. Amritphale, and D. Pal, J. Hazard. Mater. 186, 293 https://doi.org/10.1016/j.jhazmat.2010.10.109 (2011).

S.G. Xue, M. Jun, and J. Jiang, Environ. Sci. (China). 77, 1 https://doi.org/10.1016/j.jes.2018.05.016 (2018).

F. Zhu, S. Xue, W. Hartley, L. Huang, and X. Li, Environ. Sci. Pollut. Res. Int. 23, 1 https://doi.org/10.1007/s11356-015-5537-9 (2015).

W. Zhao, J. Chen, X. Chang, S. Guo, C. Srinivasakannan, C. Guo, and J. Peng, Appl. Surf. Sci. 300, 171 https://doi.org/10.1016/j.apsusc.2014.02.038 (2014).

Acknowledgements

The authors thank Chongqing University of Technology's Innovation Project (clgycx20202055) and the Innovation Project supported by Chongqing Bureau of Science and Technology (cstc2017shmsA100009) for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zeng, K., Quan, X., Jiang, Q. et al. An Efficient Dealkalization of Red Mud Through Microwave Roasting and Water Leaching. JOM 74, 3221–3231 (2022). https://doi.org/10.1007/s11837-022-05289-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05289-x