Abstract

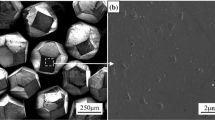

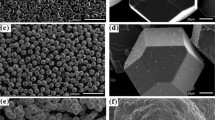

The currently available heat-sink materials cannot meet the requirements for the 5G and beyond technology. Copper (Cu)/diamond composites have been proposed because Cu and diamond are excellent thermal conductors, while diamond has a very low coefficient of thermal expansion. Mixing Cu and diamond to form a composite seems a straightforward approach. However, this simple approach has never succeeded because, chemically, Cu does not wet diamond. Therefore the Cu-diamond interface cannot be tightly bonded, leading to an inferior thermal conductivity. This study presents a modified press and sinter process for depositing Cu submicronic particles onto diamond reinforcements prior to densification by hot pressing. The initial results obtained from microstructural observations and x-ray photoelectron spectroscopy have shown that our strategy can lead to successful Cu deposition onto diamond particles. The Cu deposition leads to a well-bonded interface between the copper matrix and diamond reinforcement, ultimately resulting in excellent thermal conductivity.

Similar content being viewed by others

References

A.M. Abyzov, S.V. Kidalov, and F.M. Shakhov, J. Mater. Sci. 46, 1424 (2011).

W.Y. Tsai, G.-R. Huang, K.-K. Wang, C.-F. Chen, and J.C. Huang, Materials (Basel) 10, 1 (2017).

C. Zweben, JOM 50, 47 (1998).

J.E. Graebner, Diamond: Electronic Properties and Applications, ed. L.S. Pan and D.R. Kania (Springer, US: Boston, 1995), p. 285.

K. Yoshida, and H. Morigami, Microelectron. Reliab. 44, 303 (2004).

S.V. Kidalov, and F.M. Shakhov, Materials 2, 2467 (2009).

Q.K. Kang, X. He, S. Ren, L. Zhang, M. Wu, C. Guo, W. Cui, and X. Qu, Appl. Therm. Eng. 60, 423 (2013).

M. Zain-ul-abdein, K. Raza, F.A. Khalid, and T. Mabrouki, Mater. Des. 86, 248 (2015).

Y. Zhang, H.L. Zhang, J.H. Wu, and X.T. Wang, Scr. Mater. 65, 1097 (2011).

S. Ma, N. Zhao, C. Shi, E. Liu, C. He, F. He, and L. Ma, Appl. Surf. Sci. 402, 372 (2017).

H. Bai, N. Ma, J. Lang, C. Zhu, and Y. Ma, Compos. B 52, 182 (2013).

J. Li, X. Wang, Y. Qiao, Y. Zhang, Z. He, and H. Zhang, Scr. Mater. 109, 72 (2015).

Ł Ciupiński, M.J. Kruszewski, J. Grzonka, M. Chmielewski, R. Zielińsk, D. Moszczyńska, and A. Michalski, Mater. Des. 120, 170 (2017).

Q.L. Che, X.K. Chen, Y.Q. Ji, Y.W. Li, L.X. Wang, S.Z. Cao, Y.G. Jiang, and Z. Wang, Mater. Sci. Semicond. Process. 30, 104 (2015).

J. Grzonka, M.J. Kruszewski, M. Rosiński, Ł Ciupiński, A. Michalski, and K.J. Kurzydłowski, Mater. Charact. 99, 188 (2015).

A.M. Abyzov, S.V. Kidalov, and F.M. Shakhov, Appl. Therm. Eng. 48, 72 (2012).

ASTM, B962-17 Standard Test Methods for Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes Principle. 2017: West Conshohocken, PA.

S. Ida, T. Tsubota, S. Tanii, M. Nagata, and Y. Matsumoto, Langmuir 19, 9693 (2003).

S. Kono, T. Kageura, Y. Hayashi, S.-G. Ri, T. Teraji, D. Takeuchi, M. Ogura, H. Kodama, A. Sawabe, M. Inaba, A. Hiraiwa, and H. Kawarada, Diamond Relat. Mater. 93, 105 (2019).

G. Alba, M.P. Villar, R. Alcántara, J. Navas, and D. Araujo, Nanomaterials 10, 1193 (2020).

R.J. Stokes, and D.F. Evans, Fundamentals of Interfacial Engineering (Wiley-VCH, New York, 1996), p 531.

Acknowledgements

This research was financially supported by the University of Auckland through the Faculty Research Development Fund (FRDF) Programme (Contract No. 3717129).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hayat, M.D., Singh, H., Karumbaiah, K.M. et al. Enhanced Interfacial Bonding in Copper/Diamond Composites via Deposition of Nano-copper on Diamond Particles. JOM 74, 949–953 (2022). https://doi.org/10.1007/s11837-021-05054-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-05054-6