Abstract

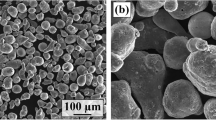

This study aims to compare the microstructure of 17–4 PH stainless steel (SS) manufactured via laser powder bed fusion (L-PBF) and laser powder directed energy deposition (LP-DED) in non-heat treated (NHT) and heat treated conditions. In addition, the room-temperature tensile behavior of heat-treated L-PBF and LP-DED 17–4 PH SS has been investigated and compared with that of the wrought counterpart with the same heat treatment conditions. The results show that the L-PBF specimens have a finer microstructure (ferrite + lath martensite) than the LP-DED ones (massive ferrite + Widmanstätten ferrite) in NHT condition. Electron backscatter diffraction analysis shows that the L-PBF and LP-DED specimens have twin-based substructure lath martensite after heat treatment. Despite the lower tensile strength of the LP-DED specimens compared with the L-PBF ones, the ductility of peak-aged LP-DED specimens was reduced due to the presence of the δ-ferrite phase having a significant plastic deformation incompatibility with the martensite.

Similar content being viewed by others

References

N. Shamsaei, A. Yadollahi, L. Bian, and S.M. Thompson, Addit. Manuf. 8, 12 (2015).

D.D. Gu, W. Meiners, K. Wissenbach, and R. Poprawe, Int. Mater. Rev. 57, 133 (2013).

T.D. Ngo, A. Kashani, G. Imbalzano, K.T.Q. Nguyen, and D. Hui, Compos. Part B 143, 172 (2018).

T.F. Babuska, B.A. Krick, D.F. Susan, and A.B. Kustas, Manuf. Lett. 28, 30 (2021).

A. Jinoop, C. Paul, and K. Bindra, J. Mater. Des. Appl. 233, 2376 (2019).

R. Molaei, A. Fatemi, N. Sanaei, J. Pegues, N. Shamsaei, S. Shao, P. Li, D.H. Warner, and N. Phan, Int. J. Fatigue 132, 1 (2020).

J. Simpson, J. Haley, C. Cramer, O. Shafer, A. Elliott, B. Peter, L. Love, and R. Dehoff, ORNL/TM-2019-1190. Oak Ridge Natl. Lab. 1190, 1 (2019).

Q. Guo, C. Zhao, M. Qu, L. Xiong, L.I. Escano, S.M.H. Hojjatzadeh, N.D. Parab, K. Fezzaa, W. Everhart, T. Sun, and L. Chen, Addit. Manuf. 28, 600 (2019).

A. Saboori, A. Aversa, G. Marchese, S. Biamino, M. Lombardi, and P. Fino, Appl. Sci. 10, 3310 (2020).

M. Ma, Z. Wang, and X. Zeng, Mater. Sci. Eng. A 685, 265 (2017).

K.N. Amato, S.M. Gaytan, L.E. Murr, E. Martinez, P.W. Shindo, J. Hernandez, S. Collins, and F. Medina, Acta Mater. 60, 2229 (2012).

F. Liu, X. Lin, H. Leng, J. Cao, Q. Liu, C. Huang, and W. Huang, Opt. Laser Technol. 45, 330 (2013).

L.L. Parimi, G. Ravi, D. Clark, and M.M. Attallah, Mater. Charact. 89, 102 (2014).

W. Xu, M. Brandt, S. Sun, J. Elambasseril, Q. Liu, K. Latham, K. Xia, and M. Qian, Acta Mater. 85, 74 (2015).

B.E. Carroll, T.A. Palmer, and A.M. Beese, Acta Mater. 87, 309 (2015).

J. Schneider, JOM 72, 1085 (2020).

C. Doñate-Buendia, R. Streubel, P. Kürnsteiner, M.B. Wilms, F. Stern, J. Tenkamp, E. Bruder, S. Barcikowski, B. Gault, K. Durst, J.H. Schleifenbaum, F. Walther, and B. Gökce, Procedia CIRP 94, 41 (2020).

M.R. Stoudt, R.E. Ricker, E.A. Lass, and L.E. Levine, JOM 69, 506 (2017).

S. Cheruvathur, E.A. Lass, and C.E. Campbell, JOM 68, 930 (2015).

W. Liu, J. Ma, M.M. Atabaki, R. Pillai, B. Kumar, U. Vasudevan, H. Sreshta, and R. Kovacevic, Lasers Manuf. Mater. Process 2, 74 (2015).

S. Cao, Determination of the Fe-Cr-Ni and Fe-Cr-Mo phase diagrams at intermediate temperatures using a novel dual-anneal diffusion-multiple approach, Ph.D thesis, The Ohio State University, 2013.

TCFE9 Thermo-Calc Software, 1 (2017).

P.D. Nezhadfar, E. Burford, K. Anderson-Wedge, B. Zhang, S. Shao, S.R. Daniewicz, and N. Shamsaei, Int. J. Fatigue 123, 168 (2019).

P.D. Nezhadfar, P. Gradl, S. Shuai, and N. Shamsaei, In Proc. 32nd Annu. Int. Solid Free. Fabr. Symp. – An Addit. Manuf. Conf. (2021).

ASTM Standard E8/E8M-13a, Standard Test Methods for Tension Testing of Metallic Materials (2006).

T. LeBrun, T. Nakamoto, K. Horikawa, and H. Kobayashi, Mater. Des. 81, 44 (2015).

L. Facchini, N. Vicente, I. Lonardelli, E. Magalini, P. Robotti, and A. Molinari, Adv. Eng. Mater. 12, 184 (2010).

M. Alnajjar, F. Christien, K. Wolski, and C. Bosch, Addit. Manuf. 25, 187 (2019).

P.D. Nezhadfar, K. Anderson-Wedge, S.R. Daniewicz, N. Phan, S. Shao, and N. Shamsaei, Addit. Manuf. 36, 101604 (2020).

R.K. Okagawa, R.D. Dixon, and D.L. Olson, Weld. Res. Suppl. 62, 204s (1983).

P.D. Nezhadfar, R. Shrestha, N. Phan, and N. Shamsaei, Int. J. Fatigue 124, 188 (2019).

C. Celada-Casero, J. Sietsma, and M.J. Santofimia, Mater. Des. 167, 107625 (2019).

D.H. Ping, S.Q. Guo, M. Imura, X. Liu, T. Ohmura, M. Ohnuma, X. Lu, T. Abe, and H. Onodera, Sci. Rep. 8, 14264 (2018).

C. Cayron, Acta Crystallogr. Sect. A 69, 498 (2012).

P.D. Nezhadfar, A. Zarei-Hanzaki, S.S. Sohn, and H.R. Abedi, Mater. Sci. Eng. A 665, 10 (2016).

G.E. Dieter and D.J. Bacon, Mechanical metallurgy (McGraw-Hill, New York, 1986).

ASTM A693-16, Standard specification for precipitation-hardening stainless and heat-resisting steel plate, sheet, and strip (2016).

M.E. Stevenson, P.D. Umberger, and S.F. Uchneat, Fracture appearance and mechanisms of deformation and fracture (ASM International, 2021).

Acknowledgements

This paper is based upon the work partially funded by the National Aeronautics and Space Administration (NASA) under Award #80MSFC19C0010. Any subjective views or opinions that might be expressed in the paper do not necessarily represent the views of NASA or the United States Government.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nezhadfar, P.D., Gradl, P.R., Shao, S. et al. Microstructure and Deformation Behavior of Additively Manufactured 17–4 Stainless Steel: Laser Powder Bed Fusion vs. Laser Powder Directed Energy Deposition. JOM 74, 1136–1148 (2022). https://doi.org/10.1007/s11837-021-05032-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-05032-y