Abstract

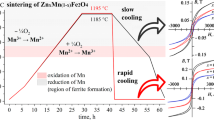

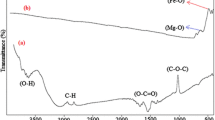

Core-shell FeCo/MnZn ferrite powders were prepared by the sol-gel method with ferrite contents ranging from 5.01 wt.% to 17.10 wt.%. The target composition for the MnZn ferrite shell was Mn0.8Zn0.2Fe2O4. The powders were compacted into bulk composites with FeCo separated by an oxide matrix using the field-assisted sintering technique (FAST) at 800°C for 10 min. All resulting compacts achieved relative density > 95%. As the MnZn ferrite content in the original core-shell powder increases from 5.01 wt.% to 17.10 wt.%, the saturation magnetization of the compacts decreases from 222 Am2/kg to 165 Am2/kg, and the coercivity increases from 772 A/m to 1654 A/m. XRD of the compacts indicates that a chemical reaction dissociates the spinel-structured MnZn ferrite into a rocksalt structured phase. Thermodynamics calculation indicates that the reaction happens between FeCo and MnZn ferrite at 800°C, but favors MnZn ferrite at temperatures ≤ 400°C. This prediction was substantiated by FAST consolidation at 400°C.

Similar content being viewed by others

References

O. Gutfleisch, M.A. Willard, E. Brück, C.H. Chen, S.G. Sankar, and J.P. Liu, Adv. Mater. 23, 821. (2011).

B.D. Cullity, and C.D. Graham, Introduction to Magnetic Materials, 2nd edn. (Wiley, Hoboken, 2008), pp 440–450.

J.M.D. Coey, Magnetism and Magnetic Materials (Cambridge University Press, Cambridge, 2009), pp 441–442.

H. Shokrollahi, and K. Janghorban, J. Mater. Process. Technol. 189, 1. (2007).

L. Yan, and B. Yan, Metals (Basel) 8, 553. (2018).

Z. Wu, X. Fan, J. Wang, G. Li, Z. Gan, and Z. Zhang, J. Alloys Compd. 617, 21. (2014).

Z.A. Munir, U. Anselmi-Tamburini, and M. Ohyanagi, J. Mater. Sci. 41, 763. (2006).

M. Suárez, A. Fernández, J.L. Menéndez, R. Torrecillas, H. U. Kessel, J. Hennicke, R. Kirchner and T. Kessel, Sintering Applications, Ed. B. Ertug (London: InTechOpen, 2013), pp. 319–342.

R.S. Sundar, and S.C. Deevi, Int. Mater. Rev. 50, 157. (2005).

M. Streckova, R. Bures, M. Faberova, P. Kurek, P. Poupcova, H. Hadraba, V. Girman, and J. Strecka, Adv. Mater. Sci. Eng. 2015, 1. (2015).

J.B. Nelson, and D.P. Riley, Proc. Phys. Soc. 57, 160. (1945).

E. Wyckoff, R. Crittenden, and Z. Kristallogra, Cryst. Mater. 63, 144. (1926).

S. Sasaki, K. Fujino, Y. Takeuchi, and R. Sadanaga, Acta Crystallogra. A 36, 904. (1980).

Ü. Özgür, Y.I. Alivov, C. Liu, A. Take, M.A. Reshchikov, and S. Dogan, J. Appl. Phys. 98, 041301. (2005).

R. Kannan, and M.S. Seehra, Phys. Rev. B 35, 6847. (1987).

R. DeHoff, Thermodynamics in Materials Science, 2nd edn. (CRC Press, Boca Raton, 2006), p 222.

M.A. Willard, T.M. Heil, and R. Goswami, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 38, 725. (2007).

W.M. Haynes, D.R. Lide, and B. Thomas, CRC Handbook of Chemistry and Physics, 97th edn. (CRC Press, Boca Raton, 2017), pp 869–908.

K. Fitzner, Thermochim. Acta 31, 227. (1979).

E. Guzik, and K. Fitzner, Cryst. Res. Technol. 23, 863. (1988).

S. Wu, A. Sun, W. Xu, Q. Zhang, F. Zhai, P. Logan, and A.A. Volinsky, J. Magn. Magn. Mater. 324, 3899. (2012).

J. Kanamori, Prog. Theor. Phys. 17, 197. (1957).

C. Kittel, Introduction to Solid State Physics, 8th edn. (Wiley, 2005), p 342.

G. Ouyang, X. Chen, Y. Liang, C. Macziewski, and J. Cui, J. Magn. Magn. Mater. 481, 234. (2019).

Acknowledgements

The authors gratefully acknowledge the support from NASA SBIR under Contract Number 80NSSC19C0358 and assistance with XRD and SEM/EDS characterization in the Swagelok Center of Surface Analysis of Materials (SCSAM) at Case Western Reserve University.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dong, B., Wang, H., Santillan, G. et al. Field-Assisted Sintering of FeCo/MnZn Ferrite Core-Shell Structured Particles. JOM 73, 3901–3909 (2021). https://doi.org/10.1007/s11837-021-04916-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04916-3