Abstract

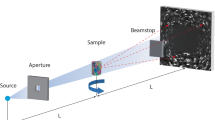

Laboratory diffraction contrast tomography (LabDCT) is a laboratory-scale x-ray microtomography technique that can be used to non-destructively map grains and grain boundaries in 3D. The fidelity of grain mapping significantly depends on the quality of grain reflections obtained from the illuminated volume of the specimen. In this article, we report the application of a novel forward modeling approach to improve the reliability of grain mapping. Through this approach, a comparison between the obtained grain reflections and simulated grain reflections can be used to perform a self-fitting operation. This can be used to optimize instrumental parameters and iteratively improve the quality of reconstruction. To demonstrate the effectiveness of the forward modeling approach, LabDCT was used to map the grains in a polycrystalline specimen of the magnesium alloy AZ91E and iteratively improve reconstruction quality significantly.

Similar content being viewed by others

References

J.P. Hirth, Metall. Trans. 3, 3047 (1972).

R. Smoluchowski, Phys. Rev. 87, 482 (1952).

H. Gleiter, Proceedings of the Second Rise International Symposium on Metallurgy and Materials Science, ed. N. Hansen et al. (Roskilde, 1981), p. 15.

C.L. Briant, Mater. Sci. Technol. 17, 1317 (2001).

B.C.P. Forsyth, R. King, and G. Metcalfe, Nat. Publ. Gr. 158, 875 (1946).

V. Randle, Mater. Sci. Technol. 26, 253 (2010).

T. Watanabe and S. Tsurekawa, J. Mater. Sci. 40, 817 (2005).

T. Watanabe, S. Tsurekawa, X. Zhao, and L. Zuo, Microstructure and Texture in Steels and Other Materials (London: Springer, 2009), pp. 43–82.

D.A. Porter and K.E. Easterling, Phase Transformations in Metals and Alloys, 3rd ed. (Boca Raton: CRC Press, 1992), pp. 310–319.

R. Keinan, H. Bale, N. Gueninchault, E.M. Lauridsen, and A.J. Shahani, Acta Mater. 148, 225 (2018).

T. Buonassisi, A.A. Istratov, M.D. Pickett, M.A. Marcus, T.F. Ciszek, and E.R. Weber, Appl. Phys. Lett. 89, 044107 (2006).

V.K. Gupta and S.R. Agnew, Int. J. Fatigue 33, 1159 (2011).

L.H. Chan, H. Weiland, S. Cheong, G.S. Rohrer, and A.D. Rollett, Appl. Texture Anal. 201, 261 (2008).

S. Rahimi, D.L. Engelberg, J.A. Duff, and T.J. Marrow, J. Microsc. 233, 423 (2008).

Y. Ma, X. Zhou, W. Huang, G.E. Thompson, X. Zhang, C. Luo, and Z. Sun, Mater. Chem. Phys. 161, 201 (2015).

S. Pawar, T.J.A. Slater, T.L. Burnett, Z. Zhou, G.M. Scamans, Z. Fan, G.E. Thompson, and P.J. Withers, Acta Mater. 133, 90 (2017).

C. Cheung and U. Erb, J. Mater. Sci. Eng. A 185, 39 (1994).

S. Kobayashi, M. Hirata, S. Tsurekawa, and T. Watanabe, Procedia Eng. 10, 112 (2011).

J.C.E. Mertens, N. Chawla, Quantifying Electromigration Processes in Sn-0.7Cu Solder with Lab-Scale X-Ray Computed Micro-Tomography. Thesis Ph.D., Arizona State University, 2015.

F.J. Humphreys, J. Mater. Sci. 36, 3833 (2001).

S.I. Wright, M.M. Nowell, and D.P. Field, Microsc. Microanal. 17, 316 (2011).

F. Han, B. Tang, H. Kou, J. Li, and Y. Feng, Mater. Sci. Eng. A 625, 28 (2015).

E. Merson, R. Brydson, and A. Brown, J. Phys. Conf. Ser. 126, 012020 (2008).

A.J. Wilkinson and T.B. Britton, Mater. Today 15, 366 (2012).

S.I. Wright and M.M. Nowell, Electron Backscatter Diffraction in Materials Science (New York: Springer, 2009), pp. 329–337.

M.D. Uchic, Computational Methods for Microstructure–Property Relationships (New York: Springer, 2011), pp. 31–53.

R.S. Sidhu and N. Chawla, Mater. Charact. 52, 225 (2004).

E.R.J.A. Hunt and P. Prasad, Serial-section Polishing Tomography (Berlin: Springer, 2008).

T.L. Burnett, R. Kelley, B. Winiarski, L. Contreras, M. Daly, A. Gholinia, M.G. Burke, and P.J. Withers, Ultramicroscopy 161, 119 (2016).

P.G. Kotula, G.S. Rohrer, and M.P. Marsh, MRS Bull. 39, 361 (2014).

Q. Zhang, S. Niverty, A.S.S. Singaravelu, J.J. Williams, E. Guo, T. Jing, and N. Chawla, Mater. Charact. 148, 52 (2019).

J.C.E. Mertens, A. Kirubanandham, and N. Chawla, Acta Mater. 102, 220 (2016).

R. Vallabhaneni, T. Stannard, C.S. Kaira, and N. Chawla, Corros. Sci. 139, 97 (2018).

S.S. Singh, C. Schwartzstein, J.J. Williams, X. Xiao, F. De Carlo, and N. Chawla, J. Alloys Compd. 602, 163 (2014).

S.S. Singh, J.J. Williams, M.F. Lin, X. Xiao, F. De Carlo, and N. Chawla, Mater. Res. Lett. 2, 217 (2014).

S.S. Singh, J.J. Williams, P. Hruby, X. Xiao, F. De Carlo, and N. Chawla, Integr. Mater. Manuf. Innov. 3, 9 (2014).

S.S. Singh, J.J. Williams, T.J. Stannard, X. Xiao, F. De Carlo, and N. Chawla, Corros. Sci. 104, 330 (2016).

J.J. Williams, K.E. Yazzie, E. Padilla, N. Chawla, X. Xiao, and F. De Carlo, Int. J. Fatigue 57, 79 (2013).

F. Eckermann, T. Suter, P.J. Uggowitzer, A. Afseth, A.J. Davenport, B.J. Connolly, M.H. Larsen, F.D. Carlo, and P. Schmutz, Corros. Sci. 50, 3455 (2008).

T.J. Stannard, J.J. Williams, S.S. Singh, A.S. Sundaram Singaravelu, X. Xiao, and N. Chawla, Corros. Sci. 138, 340 (2018).

A. King, W. Ludwig, M. Herbig, J.Y. Buffiere, A.A. Khan, N. Stevens, and T.J. Marrow, Acta Mater. 59, 6761 (2011).

W. Ludwig, A. King, P. Reischig, M. Herbig, E.M. Lauridsen, S. Schmidt, M. Proudhon, S. Forest, P. Cloetens, S. Rolland du Roscoat, J.Y. Buffiere, T.J. Marrow, and H.F. Poulsen, Mater. Sci. Eng. A 524, 69 (2009).

M. Herbig, A. King, P. Reischig, H. Proudhon, E.M. Lauridsen, J. Marrow, J.Y. Buffiere, and W. Ludwig, Acta Mater. 59, 590 (2011).

V.K. Gupta, R.P. Gangloff, and S.R. Agnew, Int. J. Fatigue 42, 131 (2012).

S.A. McDonald, P. Reischig, C. Holzner, E.M. Lauridsen, P.J. Withers, A.P. Merkle, and M. Feser, Nat. Sci. Rep. 5, 14665 (2015).

C. Holzner, L. Lavery, H. Bale, A. Merkle, S. McDonald, P. Withers, Y. Zhang, D.J. Jensen, M. Kimura, A. Lyckegaard, P. Reischig, and E.M. Lauridsen, Microsc. Today 24, 34 (2016).

H. Kong, H.C. Akakin, and S.E. Sarma, IEEE Trans. Cybern. 43, 1719 (2013).

G.E. Sotak and K.L. Boyer, Comput. Vis. Gr. Image Process. 48, 147 (1989).

H. Spont and J. Cardelino, Image Process. Line 5, 90 (2015).

Acknowledgements

SN, JJW and NC are grateful for financial support from the Office of Naval Research (ONR) through Contracts N00014-10-1-0350 and N00014-16-1-2174 (Dr. W. Mullins and W Nickerson, Program Managers). We gratefully acknowledge the use of facilities within the Center for 4D Materials Science (4DMS) at Arizona State University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Niverty, S., Sun, J., Williams, J. et al. A Forward Modeling Approach to High-Reliability Grain Mapping by Laboratory Diffraction Contrast Tomography (LabDCT). JOM 71, 2695–2704 (2019). https://doi.org/10.1007/s11837-019-03538-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03538-0