Abstract

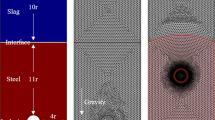

A CFD and inclusion at interface (IAT) coupled model was built and applied to simulate the floating, collision, and removal of inclusion during the Ruhrstahl Heraeus (RH) process. In the model, the influence of fluid flow, the interfacial properties, the wettability, and the viscosity of each phase are considered. The results show that during the RH process, the inclusion size tends to increase via collisions driven by the flow and buoyancy. The volume fraction of inclusion at certain aggregation points even reaches 10−4 magnitude. The different results of the model with and without the IAT boundary condition (BC) were compared, showing that with IAT BC, more inclusions are blocked by the steel–slag interface, especially the ones with a smaller size. The optimization of the bottom gas blowing rate shows that an excessively small or large blowing rate is hazardous for the inclusion removal.

Similar content being viewed by others

References

L. Zhang and W. Pluschkell, Ironmak. Steelmak. 30, 106 (2003).

J. Zhang and H. Lee, ISIJ Int. 44, 1629 (2004).

L. Zhang, JOM 65, 1138 (2013).

Y. Miki and B.G. Thomas, Metall. Mater. Trans. B 30B, 639 (1999).

S. Kimura, Y. Nabeshima, K. Nakajima, and S. Mizoguchi, Metall. Mater. Trans. B 31B, 1013 (2000).

K. Nakajima, K. Okamura, in 4th International Conference on Molten Slags and Fluxes, Sendai, Japan (ISIJ, Tokyo Japan, 1992), pp. 505–510

G.N. Shannon and S. Sridhar, High Temp. Mat. Pr.-ISR 24, 111 (2005).

S. Yang, W. Liu, and J. Li, JOM 67, 2993 (2015).

S. Yang, J. Li, C. Liu, L. Sun, and H. Yang, Metall. Mater. Trans. B 45B, 2453 (2014).

C. Liu, S. Yang, J. Li, L. Zhu, and X. Li, Metall. Mater. Trans. B 47B, 1882 (2016).

S. Sridhar and A.W. Cramb, Metall. Mater. Trans. B 31B, 406 (2000).

J. Park, I. Jung, and H. Lee, ISIJ Int. 46, 1626 (2006).

B.J. Monaghan, L. Chen, and J. Non-Cryst, Solids 347, 254 (2004).

W. Lou and M. Zhu, Metall. Mater. Trans. B 44B, 762 (2013).

D. Bouris and G. Bergeles, Metall. Mater. Trans. B 29B, 641 (1998).

J. Strandh, K. Nakajima, R. Eriksson, and P. Jonsson, ISIJ Int. 45, 1838 (2005).

J. Strandh, K. Nakajima, R. Eriksson, and P. Jonsson, ISIJ Int. 45, 1597 (2005).

H. Lei, L. Wang, Z. Wu, and J. Fan, ISIJ Int. 42, 717 (2002).

H. Tozawa, Y. Kato, K. Sorimachi, and T. Nakanishi, ISIJ Int. 39, 426 (1999).

D. Geng, J. Zheng, K. Wang, P. Wang, R. Liang, H. Liu, H. Lei, and J. He, Metall. Mater. Trans. B 46B, 1484 (2015).

L.T. Wang, Q.Y. Zhang, S.H. Peng, and Z.B. Li, ISIJ Int. 45, 331 (2005).

M. Zhu, S. Zheng, Z. Huang, and W. Gu, Steel Res. Int. 76, 718 (2005).

Y. Hu, W. Chen, H. Han, and R. Bai, Metall. Res. Technol. 114, 109 (2017).

H. Ling, L. Zhang, and C. Liu, Metall. Res. Technol. 114, 510 (2017).

H. Ling, F. Li, L. Zhang, and A.N. Conejo, Metall. Mater. Trans. B 47B, 1950 (2016).

K. Chattopadhyay, M. Isac, and R.I.L. Guthrie, Steel Res. Int. 82, 1287 (2011).

Ansys, Ansys Fluent 16.0 Theory Guide (Canonsburg: ANSYS, Inc. v.16.0, 2015).

S.K. Ajmani, S.K. Dash, S. Chandra, and C. Bhanu, ISIJ Int. 44, 82 (2004).

T. Kuwabara, K. Umezawa, K. Mori, and H. Watanabe, Trans. Iron Steel Inst. Jpn. 28, 305 (1988).

M. Van Ende, Y. Kim, M. Cho, J. Choi, and I. Jung, Metall. Mater. Trans. B 42B, 477 (2011).

M.J. Hounslow, R.L. Ryall, and V.R. Marshall, AIChE J. 34, 1821 (1988).

Acknowledgement

This research is supported by the National Science Foundation of China (No. 51574020 and 51674023).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, W., Yang, S., Li, J. et al. Numerical Investigation of Inclusion Motion at Molten Steel–Liquid Slag Interface During Ruhrstahl Heraeus (RH) Process. JOM 70, 2877–2885 (2018). https://doi.org/10.1007/s11837-018-3115-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3115-6