Abstract

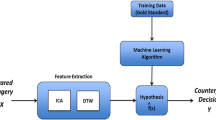

Counterfeiting in metal part manufacturing has become a major global concern. Although significant effort has been made in detecting the implementation of such counterfeits, modern approaches suffer from high expense during production, invasiveness during manufacture, and unreliability in practice if parts are damaged during use. In this paper, a practical microstructure-based counterfeit detection methodology is proposed, which draws on inherent randomness present in the microstructure as a result of the manufacturing process. An optical Physically Unclonable Function (PUF) protocol is developed which takes a micrograph as input and outputs a compact, unique string representation of the micrograph. The uniqueness of the outputs and their robustness to moderate wear and tear is demonstrated by application of the methodology to brass samples. The protocol is shown to have good discriminatory power even between samples manufactured in the same batch, and runs on the order of several seconds per part on inexpensive machines.

Similar content being viewed by others

References

P. Tuyls, J. Guajardo, L. Batina, and T. Kerins, in Security with Noisy Data: On Pri- vate Biometrics, Secure Key Storage and Anti-Counterfeiting, ed. P. Tuyles and T. Kevenaar (London: Springer, 2007), p. 293

R. Maes and I. Verbauwhede, in Towards Hardware-Intrinsic Security, ed. A.-R. Sadeghi and D. Naccache (Heidelberg: Springer, 2010), p. 3.

A. Mitrokotsa and M. Rieback, Inform. Syst. Front. 12, 491 (2010) doi:10.1007/s10796-009-9210-z.

J. Buchanan, R.P. Cowburn, A.-V. Jausovec, D. Petit, P. Seem, G. Xiong, D. Atkinson, K. Fenton, D.A. Allwood, and M.T. Bryan, Nature, 436, 475 (2005) doi:10.1038/436475a.

G.E. Suh and S. Devadas, Des. Aut. Con. 44, 9 (2007) doi:10.1145/1278480.1278484.

R. Pappu, B. Recht, J. Taylor, and N. Gershenfeld, Science, 297, 2026 (2002) doi:10.1126/science.1074376.

P. Tuyls, G.-J. Schrijen, B. Škorić, J. Van Geloven, N, Verhaegh, and B. Wolters, Lect. Notes Comput. Sci. 369 (2006) doi:10.1007/11894063_29

A.-R. Sadeghi, I. Visconti, and C. Wachsmann, in Towards Hardware-Intrinsic Security, ed. A.-R. Sadeghi and D. Naccache (Heidelberg: Springer, 2010), p. 281.

P. Tuyls and B. Škorić, in AmIware Hardware Technology Drivers of Ambient Intelligence, ed. S. Mukherjee, E. Aarts, R. Roovers, and F. Widdershoven (Dordrecht: Springer, 2006), p. 421.

M. Diephuis, S. Voloshynovskiy, T. Holotyak, N. Stendardo, and B. Keel, in Proceedings of SPIE 90280T (2014) doi:10.1117/12.2039638

J.H. Panchal, S.R. Kalidindi, and D.L. McDowell, Comput. Aided Des. 45, 4 (2013) doi:10.1016/j.cad.2012.06.006.

B.L. Adams, S. Kalidindi, and D.T. Fullwood, in Microstructure Sensitive Design for Performance Optimization (Boston, MA: ButterWorth-Heinemann, 2013), p. 67.

S.R. Niezgoda, Y.C. Yabansu, and S.R. Kalidindi, Acta Mater. 59, 6387 (2011) doi:10.1016/j.actamat.2011.06.051.

W.-H. Tsai, Comput. Gr. Image Process. 29, 377 (1985) doi:10.1016/0734-189X(85)90133-1.

J. Schindelin, I. Arganda-Carreras, E. Frise, V. Kaynig, M. Longair, T. Pietzsch, S. Preibisch, C. Rueden, S. Saalfeld, B. Schmid, J.-Y. Tinevez, D.J. White, V. Hartenstein, K. Eliceiri, P. Tomancak, and A. Cardona, Nat. Methods, 9, 676 (2012) doi:10.1038/nmeth.2019.

S. Ghosh and D.M. Dimiduk, Computational Methods for Microstructure-Property Relationships, (New York, NY: Springer, 2011), pp. 99–150.

R.T. DeHoff and F.N. Rhines, Quantitative Microscopy, (New York, NY: Mcgraw-Hill, 1968), p. 128.

S.I. Tomkeieff, Nature, 155, 107 (1945) doi:10.1038/155024a0.

R.W. Hamming, Bell Sys. Tech. J. 29, 147 (1950) doi:10.1002/j.1538-7305.1950.tb00463.x.

Acknowledgements

Portions of this work were supported by National Science Foundation Grants CPS-1329979, CNS-0915436, CMMI-1265622; and by sponsors of CERIAS. The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Dachowicz, A., Chaduvula, S.C., Atallah, M. et al. Microstructure-Based Counterfeit Detection in Metal Part Manufacturing. JOM 69, 2390–2396 (2017). https://doi.org/10.1007/s11837-017-2502-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-017-2502-8