Abstract

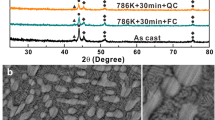

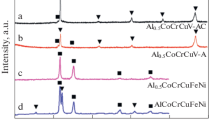

For the first time, a face-centered-cubic, single-crystal CoCrFeNiAl0.3 (designated as Al0.3), high-entropy alloy (HEA) was successfully synthesized by the Bridgman solidification (BS) method, at an extremely low withdrawal velocity through a constant temperature gradient, for which it underwent two BS steps. Specially, at the first BS step, the alloy sample underwent several morphological transitions accompanying the crystal growth from the melt. This microstructure evolves from as-cast dendrites, to equiaxed grains, and then to columnar crystals, and last to the single crystal. In particular, at the equiaxed-grain region, some visible annealing twins were observed, which indicates a low stacking fault energy of the Al0.3 alloy. Although a body-centered-cubic CoCrFeNiAl (Al1) HEA was also prepared under the same conditions, only a single columnar-crystal structure with instinctively preferential crystallographic orientations was obtained by the same procedure. A similar morphological transition from dendrites to equiaxed grains occurred at the equiaxed-grain region in Al1 alloy, but the annealing twins were not observed probably because a higher Al addition leads to a higher stacking fault energy for this alloy.

Similar content being viewed by others

References

T.M. Pollock and S. Tin, J. Propuls. Power 22, 361 (2006).

J.W. Qiao, A.C. Sun, E.W. Huang, Y. Zhang, P.K. Liaw, and C.P. Chuang, Acta Mater. 59, 4126 (2011).

K. Lu, Science 328, 319 (2010).

B. Cantor, I.T.H. Chang, P.K. Night, and A.J. Vincent, Mater. Sci. Eng. A 375, 213 (2004).

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chen, T.T. Shun, C.H. Tsau, and S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Adv. Eng. Mater. 10, 534 (2008).

X. Yang and Y. Zhang, Mater. Chem. Phys. 132, 233 (2012).

Y. Zhang, X. Yang, and P.K. Liaw, J. Miner. Met. Mater. Soc. 64, 830 (2012).

C. Zhang, F. Zhang, S. Chen, and W. Cao, JOM 64, 839 (2012).

Y.J. Zhou, Y. Zhang, Y.L. Wang, and G.L. Chen, Appl. Phys. Lett. 90, 181904 (2007).

X.F. Wang, Y. Zhang, Y. Qiao, and G.L. Chen, Intermetallics 15, 357 (2007).

S.G. Ma and Y. Zhang, Mater. Sci. Eng. A 532, 480 (2012).

M.H. Chuang, M.H. Tsai, W.R. Wang, S.J. Lin, and J.W. Yeh, Acta Mater. 59, 6308 (2011).

M.A. Hemphill, T. Yuan, G.Y. Wang, J.W. Yeh, C.W. Tsai, A. Chuang, and P.K. Liaw, Acta Mater. 60, 5723 (2012).

Y. Zhang, T.T. Zuo, Y.Q. Cheng, and P.K. Liaw, Sci. Rep. 3, 1455 (2013).

A.V. Kuznetsov, D.G. Shaysultanov, N.D. Stepanov, G.A. Salishchev, and O.N. Senkov, Mater. Sci. Eng. A 533, 107 (2012).

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle, Intermetallics 19, 698 (2011).

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu, Prog. Mater. Sci. (in press).

Y. Zhang, S.G. Ma, and J.W. Qiao, Metall. Mater. Trans. A 43A, 2625 (2012).

S. Mahajan, C.S. Pande, M.A. Imam, and B.B. Rath, Acta Mater. 45, 2633 (1997).

C.S. Pande, M.A. Imam, and B.B. Rath, Mater. Trans. 21A, 2891 (1990).

H. Gleiter, Acta Metall. 17, 1421 (1969).

S. Dash and N. Brown, Acta Metall. 11, 1067 (1963).

D.T.J. Hurle, Mechanisms of Growth of Metal Single Crystals from the Melt (Oxford: Pergamon Press Ltd, 1962).

X.F. Ding, J.P. Lin, L.Q. Zhang, Y.Q. Su, and G.L. Chen, Acta Mater. 60, 498 (2012).

L.E. Murr, Interfacial Phenomena in Metals and Alloys (Reading: Addison-Wesley Publishig Co, 1975).

A. Takeuchi and A. Inoue, Metall. Mater. Trans. 46, 2817 (2005).

J.X. Xie, H.D. Fu, Z.H. Zhang, and Y.B. Jiang, Intermetallics 23, 20 (2012).

Y. Wu, D.Q. Zhou, W.L. Song, H. Wang, Z.Y. Zhang, D. Ma, X.L. Wang, and Z.P. Lu, Phys. Rev. Lett. 109, 245506 (2012).

Acknowledgements

The authors are grateful for the Program for National Natural Science Foundation of China (NNSFC) (Contract No: 50971019). MCG acknowledges support of the Innovative Processing and Technologies Program of the National Energy Technology Laboratory’s (NETL) Strategic Center for Coal under the RES Contract DE-FE-0004000. PKL very much appreciates the financial support from the U.S. National Science Foundation (DMR-0909037, CMMI-0900271, and CMMI-1100080), the Department of Energy (DOE), Office of Nuclear Energy’s Nuclear Energy University Programs (NEUP) 00119262, and the DOE, Office of Fossil Energy, National Energy Technology Laboratory (DE-FE-0008855) with C. Huber, C. V. Cooper, D. Finotello, A. Ardell, E. Taleff, V. Cedro, R. O. Jensen, L. Tan, and S. Lesica as contract monitors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, S.G., Zhang, S.F., Gao, M.C. et al. A Successful Synthesis of the CoCrFeNiAl0.3 Single-Crystal, High-Entropy Alloy by Bridgman Solidification. JOM 65, 1751–1758 (2013). https://doi.org/10.1007/s11837-013-0733-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-013-0733-x