Abstract

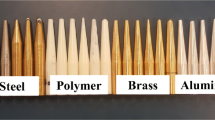

Design of the optimum preform for near net shape manufacturing is a crucial step in upsetting process design. In this study, artificial neural networks (ANN) are used to consider different interfacial friction conditions between the top and bottom die and billet interface. Two back propagation neural networks are trained based on finite element analysis results considering ten interfacial friction conditions and varying geometrical and processing parameters, to predict the optimum preform for high strength (HS) steel and commercial aluminum. Neural network predictions were verified for three new problems of both HS steel and commercial aluminum and observed that these are in close match with their simulation counterparts. It was further Experimentally verified with two commercial aluminum specimens and observed that the preform values predicted by ANN are in good agreement with experimental results.

Similar content being viewed by others

References

R. Roy, K. Chodnikiewicz, and R. Balendra, “Interpolation of Forging Preform Shapes using Neural Networks,” J. Materials Processing Technology, 45(1–4) (1994), pp. 695–702.

V. Ranatunga and J.S. Gunasekera, “UBET-based Numerical Modeling of Bulk Deformation Processes,” J. Materials Engineering and Performance, 15(1) (2006), pp. 47–52.

J.H. Lee, Y.H. Kim, and W.B. Bae, “An Upper-bound Elemental Technique Approach to the Process Design of Asymmetric Forgings,” J. Materials Processing Technology, 72(1) (1997), pp. 141–151.

Q.B. Liu, S.C. Wu, and S. Sun, “Preform Design in Axisymmetric Forging by a New FEM-UBET Method,” J. Materials Processing Technology, 74(1–3) (1998), pp, 218–222.

D.C. Ko, D.H. Kim, and B.M. Kim, “Application of Artificial Neural Network and Taguchi Method to Preform Design in Metal Forming Considering Workability,” International Journal of Machine Tools & Manufacture, 39(5) (1999), pp. 771–785.

A. Srikanth and N. Zabaras, “Shape Optimization and Preform Design in Metal Forming Processes,” Computer Methods in Applied Mechanics and Engineering, 190(13–14) (2000), pp. 1859–1901.

C.C. Chang and A.N. Bramley, “Forging Preform Design Using a Reverse Simulation Approach with the Upper Bound Finite Element Procedure,” Proceedings of The Institution of Mechanical Engineers Part C-Joumal of Mechanical Engineering Science, 214(1) (2000), pp. 127–136.

A. Bramley, “UBET and TEUBA: Fast Methods for Forging Simulation and Preform Design,” J. Materials Processing Technology, Special Issue, 116(1) (2001), pp. 62–66.

C.A.C. Antonio and N.M. Dourado, “Metal-forming Process Optimisation by Inverse Evolutionary Search,” J. Materials Processing Technology, 121(2–3) (2002), pp. 403–413.

H. Shim, “Optimal Preform Design for the Free Forging of 3D Shapes by the Sensitivity Method,” J. Materials Processing Technology; 134(1) (2003), pp. 99–107.

B.I. Tomov, V.I. Gagov, and R.H. Radev, “Numerical Simulations of Hot Die Forging Processes using Finite Element Method,” J. Materials Processing Technology, Part 1 Special Issue 153 (2004), pp. 352–358.

H. Ou et al., “An FE Simulation and Optimisation Approach for the Forging of Aeroengine Components,” J. Materials Processing Technology, 151(1–3) (2004), pp. 208–216.

M. Poursina et al., “Preform Optimal Design in Metal Forging using Genetic Algorithms,” Engineering Computations, 21(5–6) (2004), pp. 631–650.

N. Thiyagarajan and R.V. Grandhi, “Multi-level Design Process for 3-D Preform Shape Optimization in Metal Forming,” J. Materials Processing Technology, 170(1–2) (2005), pp. 421–429.

J. Repalle and R.V. Grandhi, “Reliability-based Preform Shape Design in Forging,” Communications in Numerical Methods in Engineering, 21(11) (2005), pp. 607–617.

C.C. Antonio, C.F. Castro, and L.C. Sousa, “Eliminating Forging Defects using Genetic Algorithms,” Materials and Manufacturing Processes, 20(3) (2005), pp. 509–522.

J.J. Park and H.S. Hwang, “Preform Design for Precision Forging of an Asymmetric Rib-web Type Component,” J. Materials Processing Technology, 187 (2007), pp. 595–599.

G. Poshala and R Ganesan, “An Analysis of Formability of Aluminium Preforms using Neural Network,” J. Materials Processing Technology, 205(1–3) (2008), pp. 272–282.

Haluk Tumer and Fazil O. Sonmez, “Optimum Shape Design of Die and Preform for Improved Hardness Distribution in Cold Forged Parts,” J. of Materials Processing Technology, 197 (2008), pp. 356–364.

J. Hertz and A. Krogh, Introduction to the Theory of Neural Networks (Reading, MA: Addison-Wesley Publishing Company, 1991).

S. Kalpakjian and S.R. Schmid, Manufacturing Eng. and Technology, Fourth Edition (Delhi, India: Pearson Education India, 2004).

M.A. Meyereand and K.K. Chawla, Mechanical Behavior of Materials (Upper Saddle River, NJ: Prentice Hall, 1999).

MSC.Marc, User’s manual (MSC Software Corporation, Santa Ana, California 92707 USA, 2005).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Pathak, K.K., Kaviti, A.K. & Hora, M.S. The application of neural networks in the preform design of the upsetting process. JOM 62, 55–59 (2010). https://doi.org/10.1007/s11837-010-0079-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-010-0079-6