Abstract

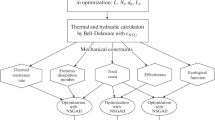

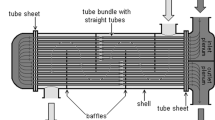

This paper presents a comprehensive state-of-the-art review of optimization by evolutionary computation methods of shell and tubes heat exchangers (STHE) of single segmental baffles. It is seen that the heat transfer coefficient to the shell side is calculated by the Kern method or by the Bell Delaware method, and that the pressure drop to the shell side is calculated by the Kern method or by the Bell Delaware method or by the Peters and Timmershaus method. It is verified the use of evolutionary computation algorithms in single-objective and multiobjective optimization of STHE, and that most related work used the total cost function of STHE. And among the contributions presented, there were implementations and applications of different evolutionary computation algorithms, or study of the STHE optimization problem by different objective functions, such as ecological, entransy dissipation, field synergy, and cost of the life cycle. Also, it was possible to verify some gaps in the work related to STHE optimization, among them, can be cited the need for greater application of decision-making methods that relate technical, economic and managerial aspects applied to the solution of the STHE. And it is suggested for future work the development of the STHE model subject to delimited uncertainties; and the formalization of a standard STHE optimization problem, so that it can serve as a reference for comparing the different optimization algorithms, and applying metrics to evaluate the advantages that are obtained when using a new algorithm for the same problem.

Similar content being viewed by others

Abbreviations

- ABC:

-

Artificial bee colony

- ACO:

-

Ant colony optimization

- ARGA:

-

Adaptive range genetic algorithm

- BA:

-

Bat algorithm

- BBO:

-

Biogeography-based algorithm

- BSA:

-

Backtracking search algorithm

- BF:

-

Brute force

- CC:

-

Capital cost

- CEGA:

-

Controlled elitist genetic algorithm

- CI:

-

Cohort intelligence

- CSA:

-

Cuckoo search algorithm

- CSO:

-

Civilized swarm optimization

- DE:

-

Differential evolution

- DEACO:

-

Differential evolution and ant colony optimization

- EA:

-

Evolutionary algorithms

- EDNFF:

-

Entransy dissipation number to fluid friction

- EDNHC:

-

Entransy dissipation number to heat conduction

- EI:

-

Economic index

- E-JA:

-

Elitist-Jaya algorithm

- ENI:

-

Environmental index

- FA:

-

Firefly algorithm

- FOA:

-

Falcon optimization algorithm

- GA:

-

Genetic algorithm

- GSA:

-

Gravitational search algorithm

- HSA:

-

Harmony search algorithm

- ICA:

-

Imperialist competitive algorithm

- ITHS:

-

Intelligent tuned harmony search

- I-ITHS:

-

Improved intelligent tuned harmony search

- JA:

-

Jaya algorithm

- LCC:

-

Life cycle cost

- MCS:

-

Monte Carlo simulation

- MOO:

-

Multiobjective optimization

- MOPSO:

-

Multi-objective particle swarm optimization

- MTLBO:

-

Modified teaching–learning-based optimization algorithm

- NSGA II:

-

Non-dominated sorting genetic algorithm II

- NR:

-

Not reported

- OC:

-

Operating cost

- PP:

-

Predador prey

- PROMETHEE:

-

Preference ranking organization method for enrichment evaluations

- PSO:

-

Particle swarm optimization

- QPSO:

-

Quantum particle swarm optimization

- QPSOZ:

-

Quantum particle swarm optimization combined with Zaslavskii chaotic map sequences

- SA:

-

Simulated annealing

- SCA:

-

Sine–cosine algorithm

- SCAOCE:

-

Sum of annual operating cost and exergetic cost

- SI:

-

Sustainability index

- SOI:

-

Social index

- SOO:

-

Single-objective optimization

- SSFSN:

-

Shell side field synergy number

- STHE:

-

Shell and tube heat exchanger

- TC:

-

Total cost

- TDE:

-

Tsallis differential evolution

- TEDN:

-

Total entransy dissipation number

- TEMA:

-

Tubular Exchanger Manufacturers Association

- TOPSIS:

-

Technique for order performance by similarity to the ideal solution

- A :

-

Area, or cross flow area (m\(^2\))

- a :

-

Tube layout

- AA :

-

First term of the Bhatti and Shah correlation

- BB :

-

Second term of the Bhatti and Shah correlation, this factor multiplies the Reynolds number of the flow inside the tubes

- bc :

-

Baffle cut (%)

- cc :

-

Dittus-Bolter correlation constant

- CL :

-

Tube layout constant

- CTP :

-

Tube count constant

- d :

-

Diameter (m)

- D :

-

Diameter (m)

- esp :

-

Wall thickness of the tubes (m)

- f :

-

Friction factor in the flow in the shell

- FF :

-

Correction factor for logarithmic mean temperature difference

- FQPT :

-

Pressure drop factor in the tubes

- G :

-

Fluid mass velocity based on the minimum free area (kg/m\(^2\) s)

- h :

-

Heat transfer coefficient (W/m\(^2\) K)

- k :

-

Thermal conductivity of fluid (W/m K)

- L :

-

Spacing or length (m)

- \(\dot{m}\) :

-

Mass flow rate (kg/s)

- N :

-

Number of sealing strips or number of tubes or number of baffles

- np :

-

Number of passes

- Nu:

-

Nusselt number

- P :

-

Pitch (m) or pumping power (W)

- Pr:

-

Prandtl number

- Q :

-

Heat transfer rate (W)

- Re:

-

Reynolds number

- v :

-

Flow velocity (m/s)

- \(\delta\) :

-

Clearance (m)

- \(\Delta P\) :

-

Pressure drop (Pa)

- \(\varepsilon\) :

-

Effectiveness

- \(\theta\) :

-

Angle between two radii intersected at the inside shell wall with the baffle cut (radians)

- \(\phi\) :

-

Viscosity correction factor.

- \(\rho\) :

-

Density (kg/m\(^3\))

- \(\sigma\) :

-

Ratio of minimum free flow area to frontal area

- b :

-

Baffles

- e :

-

Equivalent

- i :

-

Inside the tube

- o :

-

Outside the tube

- p :

-

Pattern

- s :

-

Shell side

- t :

-

Tubes side

- otl :

-

Tube bundle

- ss :

-

Sealing strips

- s, t :

-

Shell side and tubes side

- \(c_1\) :

-

Empirical coefficient

- \(f_{alocat}\) :

-

Fluid allocation

- \(f_{ss}\) :

-

Friction factor

- \(E_{E}'\) :

-

Ecological (W)

- \(k_c\) :

-

Contraction loss coefficient at tube entrance

- \(k_e\) :

-

Expansion loss coefficient at tube outlet

- \(I_s\) :

-

Area increment

- \(j_{hs}\) :

-

Thermal factor

- \(m_1\) :

-

Empirical coefficient

- \(r_d\) :

-

Fouling factor \((\hbox {m}^{2}\,^{\circ }\hbox {C}/\hbox {W})\)

- \(R_{fall}\) :

-

Allowed fouling resistance \((\hbox {m}^2\,^{\circ }\hbox {C}/\hbox {W})\)

- \(sh_{types}\) :

-

Shell head types

- \(T_{c,o}\) :

-

Cold side fluid output temperature \((^{\circ }\hbox {C})\)

- \(t_{mat}\) :

-

Tube material

References

Shah RK, Sekulic DP (2003) Fundamentals of heat exchanger design. Wiley

TEMA (2007) Standards of the Tubular Exchanger Manufacturers Association and others. Tubular Exchanger Manufacturers Association Inc., Tarrytown

ASME (2013) Boiler and pressure vessel codes: section VIII rules for construction of pressure vessels. The American Society of Mechanical Engineers, Two Park Avenue, New York

Kern DQ (1950) Process heat transfer. Tata McGraw-Hill Education, New York

Tinker T (1951) Shell-side characteristic of shell-and-tube heat exchangers, Parts i, ii, and iii. General Discussion on Heat Transfer. In: Proceedings of institute of mechanical engineers, London, pp 89–116

Tinker T (1958) Shell side characteristics of shell and tube heat exchangers: a simplified rating system for commercial heat exchangers. Trans ASME 80:36–52

Bell KJ (1963) Final report of the cooperative research program on shell and tube heat exchangers. University of Delaware, Engineering Experimental Station, Newark

Palen J, Taborek J (1969) Solution of shell side flow pressure drop and heat transfer by stream analysis method. Chem Eng Prog Symp Ser 65:53–63

Ribeiro MCC (1984) Comparação de métodos de cálculo termo-hidraulico para trocadores de calor casco e tubo, sem mudança de fase. Master’s thesis, Universidade Estadual de Campinas

Bell KJ (2004) Heat exchanger design for the process industries. In: ASME 2004 heat transfer/fluids engineering summer conference. American Society of Mechanical Engineers, pp 921–959

Peters MS, Timmerhaus KD (1991) Plant design and economics for chemical engineers. McGraw-Hill

Patel VK, Rao RV (2010) Design optimization of shell-and-tube heat exchanger using particle swarm optimization technique. Appl Therm Eng 30(11–12):1417–1425. https://doi.org/10.1016/j.applthermaleng.2010.03.001

Selbaş R, Kızılkan Ö, Reppich M (2006) A new design approach for shell-and-tube heat exchangers using genetic algorithms from economic point of view. Chem Eng Process Process Intensif 45(4):268–275

Wildi-Tremblay P, Gosselin L (2007) Minimizing shell-and-tube heat exchanger cost with genetic algorithms and considering maintenance. Int J Energy Res 31(9):867–885

Babu BV, Munawar S (2007) Differential evolution strategies for optimal design of shell-and-tube heat exchangers. Chem Eng Sci 62(14):3720–3739. https://doi.org/10.1016/j.ces.2007.03.039

Caputo AC, Pelagagge PM, Salini P (2008) Heat exchanger design based on economic optimisation. Appl Therm Eng 28(10):1151–1159

Fesanghary M, Damangir E, Soleimani I (2009) Design optimization of shell and tube heat exchangers using global sensitivity analysis and harmony search algorithm. Appl Therm Eng 29(5–6):1026–1031. https://doi.org/10.1016/j.applthermaleng.2008.05.018

Ravagnani MASS, Silva AP, Biscaia EC, Caballero JA (2009) Optimal design of shell-and-tube heat exchangers using particle swarm optimization. Ind Eng Chem Res 48(6):2927–2935. https://doi.org/10.1021/ie800728n

Guo J, Xu M, Cheng L (2009) The application of field synergy number in shell-and-tube heat exchanger optimization design. Appl Energy 86(10):2079–2087. https://doi.org/10.1016/j.apenergy.2009.01.013

Guo J, Xu M (2012) The application of entransy dissipation theory in optimization design of heat exchanger. Appl Therm Eng 36(1):227–235. https://doi.org/10.1016/j.applthermaleng.2011.12.043

Şahin AŞ, Kılıç B, Kılıç U (2011) Design and economic optimization of shell and tube heat exchangers using artificial bee colony (abc) algorithm. Energy Convers Manag 52(11):3356–3362

Cocco V, Rodrigo A, Duck K, Alessandro F, Coelho S, Venkata R (2012) A chaotic quantum-behaved particle swarm approach applied to optimization of heat exchangers. Appl Therm Eng 42:119–128. https://doi.org/10.1016/j.applthermaleng.2012.03.022

Caputo AC, Pelagagge PM, Salini P (2011) Joint economic optimization of heat exchanger design and maintenance policy. Appl Therm Eng 31(8–9):1381–1392

Sanaye S, Hajabdollahi H (2010) Multi-objective optimization of shell and tube heat exchangers. Appl Therm Eng 30(14–15):1937–1945. https://doi.org/10.1016/j.applthermaleng.2010.04.018

Hadidi A, Hadidi M, Nazari A (2013) A new design approach for shell-and-tube heat exchangers using imperialist competitive algorithm (ICA) from economic point of view. Energy Convers Manag 67:66–74. https://doi.org/10.1016/j.enconman.2012.11.017

Hadidi A, Nazari A (2013) Design and economic optimization of shell-and-tube heat exchangers using biogeography-based (BBO) algorithm. Appl Therm Eng 51(1–2):1263–1272. https://doi.org/10.1016/j.applthermaleng.2012.12.002

Rao RV, Patel V (2013) Multi-objective optimization of heat exchangers using a modified teaching-learning-based optimization algorithm. Appl Math Model 37(3):1147–1162. https://doi.org/10.1016/j.apm.2012.03.043

Fettaka S, Thibault J, Gupta Y (2013) Design of shell-and-tube heat exchangers using multiobjective optimization. Int J Heat Mass Transf 60(1):343–354. https://doi.org/10.1016/j.ijheatmasstransfer.2012.12.047

Ghanei A, Assareh E, Biglari M, Ghanbarzadeh A, Noghrehabadi AR (2014) Thermal-economic multi-objective optimization of shell and tube heat exchanger using particle swarm optimization (PSO). Heat Mass Transf. https://doi.org/10.1007/s00231-014-1340-2

Amini M, Bazargan M (2014) Two objective optimization in shell-and-tube heat exchangers using genetic algorithm. Appl Therm Eng 69(1–2):278–285. https://doi.org/10.1016/j.applthermaleng.2013.11.034

Asadi M, Song Y, Sunden B, Xie G (2014) Economic optimization design of shell-and-tube heat exchangers by a cuckoo-search-algorithm. Appl Therm Eng 73(1):1032–1040. https://doi.org/10.1016/j.applthermaleng.2014.08.061

Mohanty DK (2016a) Application of firefly algorithm for design optimization of a shell and tube heat exchanger from economic point of view. Int J Therm Sci 102:228–238

Mohanty DK (2016b) Gravitational search algorithm for economic optimization design of a shell and tube heat exchanger. Appl Therm Eng 107:184–193

Tharakeshwar T, Seetharamu K, Prasad BD (2017) Multi-objective optimization using bat algorithm for shell and tube heat exchangers. Appl Therm Eng 110:1029–1038

Rao RV, Saroj A (2017) Economic optimization of shell-and-tube heat exchanger using jaya algorithm with maintenance consideration. Appl Therm Eng 116:473–487

de Vasconcelos Segundo EH, Amoroso AL, Mariani VC, dos Santos Coelho L (2017) Economic optimization design for shell-and-tube heat exchangers by a tsallis differential evolution. Appl Therm Eng 111:143–151

Barros JJC, Coira ML, de la Cruz López MP, del Caño GA (2018) Sustainability optimisation of shell and tube heat exchanger, using a new integrated methodology. J Clean Prod 200:552–567

Saldanha W, Soares G, Machado-Coelho T, dos Santos E, Ekel P (2017) Choosing the best evolutionary algorithm to optimize the multiobjective shell-and-tube heat exchanger design problem using promethee. Appl Therm Eng 127:1049–1061. https://doi.org/10.1016/j.applthermaleng.2017.08.052

Iyer VH, Mahesh S, Malpani R, Sapre M, Kulkarni AJ (2019) Adaptive range genetic algorithm: a hybrid optimization approach and its application in the design and economic optimization of shell-and-tube heat exchanger. Eng Appl Artif Intell 85:444–461

de Vasconcelos Segundo EH, Mariani VC, dos Santos Coelho L (2019) Design of heat exchangers using falcon optimization algorithm. Appl Therm Eng 156:119–144

Rodríguez MBR, Rodríguez JLM, Fontes CHDO (2019) Thermo ecological optimization of shell and tube heat exchangers using NSGA II. Appl Therm Eng 156:91–98

Turgut OE, Turgut MS, Coban MT (2014) Design and economic investigation of shell and tube heat exchangers using improved intelligent tuned Harmony Search algorithm. Ain Shams Eng J 5(4):1215–1231. https://doi.org/10.1016/j.asej.2014.05.007 http://linkinghub.elsevier.com/retrieve/pii/S2090447914000756

Dhavle SV, Kulkarni AJ, Shastri A, Kale IR (2018) Design and economic optimization of shell-and-tube heat exchanger using cohort intelligence algorithm. Neural Comput Appl 30(1):111–125

Özçelik Y (2007) Exergetic optimization of shell and tube heat exchangers using a genetic based algorithm. Appl Therm Eng 27:1849–1856. https://doi.org/10.1016/j.applthermaleng.2007.01.007

Rao RV, Saroj A (2017) Constrained economic optimization of shell-and-tube heat exchangers using elitist-jaya algorithm. Energy 128:785–800

Rao R, Patel V (2011) Design optimization of shell and tube heat exchangers using swarm optimization algorithms. Proc Inst Mech Eng Part A J Power Energy 225(5):619–634

Wong JY, Sharma S, Rangaiah G (2016) Design of shell-and-tube heat exchangers for multiple objectives using elitist non-dominated sorting genetic algorithm with termination criteria. Appl Therm Eng 93:888–899

Hajabdollahi H, Ahmadi P, Dincer I (2012) Exergetic optimization of shell-and-tube heat exchangers using NSGA-II. Heat Transf Eng 33(7):618–628

Lahiri SK, Khalfe NM, Wadhwa SK (2012) Particle swarm optimization technique for the optimal design of shell and tube heat exchangers. Chem Prod Process Model 7(1):1–38

Lahiri SK, Khalfe N (2014) Improve shell and tube heat exchangers design by hybrid differential evolution and ant colony optimization technique. Asia Pac J Chem Eng 9(3):431–448

Fraas AP (1989) Heat exchanger design. Wiley

Kakac S, Liu H (2012) Heat exchangers: selection, rating, and thermal design. CRC Press, Boca Raton

Turgut OE (2017) Thermal and economical optimization of a shell and tube evaporator using hybrid backtracking search-sine–cosine algorithm. Arab J Sci Eng 42(5):2105–2123

Serth RW, Lestina T (2014) Process heat transfer: principles, applications and rules of thumb. Academic Press, London

Towler G, Sinnott R (2008) Chemical engineering design: principles, practice and economics of plant and process design. Elsevier, Amsterdam

Sinnott R, Richardson JF, Coulson J (1989) Chemical engineering: an introduction to chemical engineering design. Elsevier, Amsterdam

Thakore SB, Bhatt BI (2007) Introduction to process engineering and design. McGraw-Hill Education, New York

Wills M, Johnston D, Harwell A (1984) A new and accurate hand calculation method for shell-side pressure drop and flow distribution. In: 22nd national heat transfer conference, HTD, ASME, vol 36

Mirzaei M, Hajabdollahi H, Fadakar H (2017) Multi-objective optimization of shell-and-tube heat exchanger by constructal theory. Appl Therm Eng 125:9–19

Lee PS, Garimella SV, Liu D (2005) Investigation of heat transfer in rectangular microchannels. Int J Heat Mass Transf 48(9):1688–1704

Sadeghzadeh H, Aliehyaei M, Rosen MA (2015) Optimization of a finned shell and tube heat exchanger using a multi-objective optimization genetic algorithm. Sustainability 7(9):11679–11695

Incropera FP, Lavine AS, Bergman TL, DeWitt DP (2007) Fundamentals of heat and mass transfer. Wiley, Hoboken

Hewitt GF (1998) Heat exchanger design handbook, 1998. Begell House, New York

Saunders E (1988) Heat exchangers: selection. Design and construction. Longman Scientific and Technical, London

Rao RV, Saroj A (2018) Constrained economic optimization of shell-and-tube heat exchangers using a self-adaptive multipopulation elitist-jaya algorithm. J Therm Sci Eng Appl 10(4):041001

Shi M, Wang Z (1996) Principia and design of heat transfer device. Southeast University Press [in Chinese]

Taal M, Bulatov I, Klemeš J, Stehlik P (2003) Cost estimation and energy price forecasts for economic evaluation of retrofit projects. Appl Therm Eng 23(14):1819–1835

Purohit G (1983) Estimating costs of shell-and-tube heat exchangers. Chem Eng 90(17):56–67

Caputo AC, Pelagagge PM, Salini P (2016) Manufacturing cost model for heat exchangers optimization. Appl Therm Eng 94:513–533

Nasr MJ, Polley G (2000) An algorithm for cost comparison of optimized shell-and-tube heat exchangers with tube inserts and plain tubes. Chem Eng Technol Ind Chem Plant Equip Process Eng Biotechnol 23(3):267–272

Azad AV, Amidpour M (2011) Economic optimization of shell and tube heat exchanger based on constructal theory. Energy 36(2):1087–1096. https://doi.org/10.1016/j.energy.2010.11.041

Yang J, Fan A, Liu W, Jacobi AM (2014) Optimization of shell-and-tube heat exchangers conforming to TEMA standards with designs motivated by constructal theory. Energy Convers Manag 78:468–476. https://doi.org/10.1016/j.enconman.2013.11.008

Caputo AC, Salini P (2012) Robust approach for shell and tube exchangers optimization under uncertain heat transfer estimation. In: Proceedings of ENCIT 2012

Hajabdollahi H, Ahmadi P, Dincer I (2011) Thermoeconomic optimization of a shell and tube condenser using both genetic algorithm and particle swarm. Int J Refrig 34(4):1066–1076

Yang J, Oh SR, Liu W (2014) Optimization of shell-and-tube heat exchangers using a general design approach motivated by constructal theory. Int J Heat Mass Transf 77:1144–1154

Genceli O (1999) Heat exchangers. Birsen Book Company, Istanbul

Kakaç S (1996) Heat exchanger design course. Fundamentals and applications, vol 3. ITU Faculty of Mechanical Engineering, Istanbul

Schlunder EU (1983) Heat exchanger design handbook. Hemisphere Publishing, New York

Sinnot R (1996) Coulson & Richardson’s chemical engineering. Butterworth-Heinemann, Oxford

Smith RM (2005) Chemical process: design and integration. Wiley, Hoboken

Allen B, Gosselin L (2008) Optimal geometry and flow arrangement for minimizing the cost of shell-and-tube condensers. Int J Energy Res 32(10):958–969

Zarei O, Fesanghary M, Farshi B, Saffar RJ, Razfar M (2009) Optimization of multi-pass face-milling via harmony search algorithm. J Mater Process Technol 209(5):2386–2392

Turton R, Bailie RC, Whiting WB, Shaeiwitz JA (2008) Analysis, synthesis and design of chemical processes. Pearson Education, London

Ponce-Ortega JM, Serna-González M, Jiménez-Gutiérrez A (2009) Use of genetic algorithms for the optimal design of shell-and-tube heat exchangers. Appl Therm Eng 29(2–3):203–209. https://doi.org/10.1016/j.applthermaleng.2007.06.040

Peters MS, Timmerhaus KD, West RE, Timmerhaus K, West R (1980) Plant design and economics for chemical engineers. McGraw-Hill New York, New York

Chaudhuri PD, Diwekar UM (1997) An automated approach for the optimal design of heat exchangers. Ind Eng Chem Res 36:3685–3693. https://doi.org/10.1021/ie970010h

Tayal MC, Fu Y, Diwekar UM (1999) Optimal design of heat exchangers: a genetic algorithm framework. Ind Eng Chem Res 38(2):456–467. https://doi.org/10.1021/ie980308n

Ozden E, Tari I (2010) Shell side cfd analysis of a small shell-and-tube heat exchanger. Energy Convers Manag 51(5):1004–1014

Pal E, Kumar I, Joshi JB, Maheshwari N (2016) Cfd simulations of shell-side flow in a shell-and-tube type heat exchanger with and without baffles. Chem Eng Sci 143:314–340

Wang Q, Chen Q, Chen G, Zeng M (2009) Numerical investigation on combined multiple shell-pass shell-and-tube heat exchanger with continuous helical baffles. Int J Heat Mass Transf 52(5):1214–1222

Zhang JF, He YL, Tao WQ (2009) 3d numerical simulation on shell-and-tube heat exchangers with middle-overlapped helical baffles and continuous baffles-part i: Numerical model and results of whole heat exchanger with middle-overlapped helical baffles. Int J Heat Mass Transf 52(23):5371–5380

Wang S, Xiao J, Wang J, Jian G, Wen J, Zhang Z (2018) Application of response surface method and multi-objective genetic algorithm to configuration optimization of shell-and-tube heat exchanger with fold helical baffles. Appl Therm Eng 129:512–520

Wen J, Yang H, Jian G, Tong X, Li K, Wang S (2016) Energy and cost optimization of shell and tube heat exchanger with helical baffles using kriging metamodel based on moga. Int J Heat Mass Transf 98:29–39

Wen J, Gu X, Wang M, Wang S, Tu J (2017) Numerical investigation on the multi-objective optimization of a shell-and-tube heat exchanger with helical baffles. Int Commun Heat Mass Transf 89:91–97

Gu X, Wang M, Liu Y, Wang S et al (2018) Multi-parameter optimization of shell-and-tube heat exchanger with helical baffles based on entransy theory. Appl Therm Eng 130:804–813

Shahril S, Quadir G, Amin N, Badruddin IA (2017) Thermo hydraulic performance analysis of a shell-and-double concentric tube heat exchanger using cfd. Int J Heat Mass Transf 105:781–798

You Y, Fan A, Huang S, Liu W (2012) Numerical modeling and experimental validation of heat transfer and flow resistance on the shell side of a shell-and-tube heat exchanger with flower baffles. Int J Heat Mass Transf 55(25):7561–7569

You Y, Chen Y, Xie M, Luo X, Jiao L, Huang S (2015) Numerical simulation and performance improvement for a small size shell-and-tube heat exchanger with trefoil-hole baffles. Appl Therm Eng 89:220–228

Tan XH, Zhu DS, Zhou GY, Zeng LD (2012) Experimental and numerical study of convective heat transfer and fluid flow in twisted oval tubes. Int J Heat Mass Transf 55(17):4701–4710

Yang J, Liu W (2015) Numerical investigation on a novel shell-and-tube heat exchanger with plate baffles and experimental validation. Energy Convers Manag 101:689–696

Dong Q, Wang Y, Liu M (2008) Numerical and experimental investigation of shellside characteristics for rodbaffle heat exchanger. Appl Therm Eng 28(7):651–660

Wang X, Zheng N, Liu Z, Liu W (2018) Numerical analysis and optimization study on shell-side performances of a shell and tube heat exchanger with staggered baffles. Int J Heat Mass Transf 124:247–259

Bhutta MMA, Hayat N, Bashir MH, Khan AR, Ahmad KN, Khan S (2012) Cfd applications in various heat exchangers design: a review. Appl Therm Eng 32:1–12

Pedrycz W, Ekel P, Parreiras R (2011) Fuzzy multicriteria decision-making: models, methods and applications. Wiley, Hoboken

Sobol IM (1993) Sensitivity estimates for nonlinear mathematical models. Math Model Comput Exp 1(4):407–414

Caputo AC, Pelagagge PM, Salini P (2008) Heat exchanger design based on economic optimisation. Appl Therm Eng 28(10):1151–1159. https://doi.org/10.1016/j.applthermaleng.2007.08.010

Muralikrishna K, Shenoy U (2000) Heat exchanger design targets for minimum area and cost. Chem Eng Res Des 78(2):161–167

Sinnott CJRK, Richardson J (1996) Chemical enginering design, vol 6. Elsevier, Amsterdam

Turgut OE, Turgut MS, Coban MT (2014) Design and economic investigation of shell and tube heat exchangers using improved intelligent tuned harmony search algorithm. Ain Shams Eng J 5(4):1215–1231

Khosravi R, Khosravi A, Nahavandi S, Hajabdollahi H (2015) Effectiveness of evolutionary algorithms for optimization of heat exchangers. Energy Convers Manag 89:281–288

Mariani VC, Duck ARK, Guerra FA, dos Santos Coelho L, Rao RV (2012) A chaotic quantum-behaved particle swarm approach applied to optimization of heat exchangers. Appl Therm Eng 42:119–128

Sadeghzadeh H, Ehyaei M, Rosen M (2015) Techno-economic optimization of a shell and tube heat exchanger by genetic and particle swarm algorithms. Energy Convers Manag 93:84–91. https://doi.org/10.1016/j.enconman.2015.01.007

Deb K (2001) Multi-objective optimization using evolutionary algorithms. Wiley, Chichester

Riquelme N, Von, (2015) Lücken C, Baran B (2015) Performance metrics in multi-objective optimization. In: Computing conference (CLEI). Latin American, IEEE, pp 1–11

Martin BAC (2016) MCDM: multi-criteria decision making methods for crisp data, r package version 1.2. https://CRAN.R-project.org/package=MCDM

Guo Z, Li D, Wang B (1998) A novel concept for convective heat transfer enhancement. Int J Heat Mass Transf 41(14):2221–2225

Guo ZY, Tao WQ, Shah R (2005) The field synergy (coordination) principle and its applications in enhancing single phase convective heat transfer. Int J Heat Mass Transf 48(9):1797–1807

Guo J, Cheng L, Xu M (2009) Entransy dissipation number and its application to heat exchanger performance evaluation. Chin Sci Bull 54(15):2708–2713

Angulo-Brown F (1991) An ecological optimization criterion for finite-time heat engines. J Appl Phys 69(11):7465–7469

Eryener D (2006) Thermoeconomic optimization of baffle spacing for shell and tube heat exchangers. Energy Convers Manag 47(11–12):1478–1489

Bejan A (2000) Shape and structure, from engineering to nature. Cambridge University Press, Cambridge

Sinnott R (2005) Heat transfer equipment, Coulson & Richardson’s chemical engineering. Butterworth-Heinemann

Branke J, Branke J, Deb K, Miettinen K, Slowiński R (2008) Multiobjective optimization: interactive and evolutionary approaches, vol 5252. Springer, Berlin

Cho SM (1987) Uncertainty analysis of heat exchanger thermal-hydraulic designs. Heat Transf Eng 8(2):63–74

Badar MA, Zubair SM, Sheikh AK (1993) Uncertainty analysis of heat-exchanger thermal designs using the monte carlo simulation technique. Energy 18(8):859–866

Knetsch T, Hauptmanns U (2005) Integration of stochastic effects and data uncertainties into the design of process equipment. Risk Anal Int J 25(1):189–198

Clarke D, Vasquez V, Whiting W, Greiner M (2001) Sensitivity and uncertainty analysis of heat-exchanger designs to physical properties estimation. Appl Therm Eng 21(10):993–1017

Haseler L, Owen R, Sardesai R (1983) The sensitivity of heat exchanger calculations to uncertainties in the physical properties of the process fluids. Proc Inst Mech Eng Part A Power Process Eng 197(3):171–178

Shilling RL, Rudy MP, Rudy TM (2011) Risk-based design margin selection for heat exchangers. Heat Transf Eng 32(3–4):307–313

Zhiqiang X (2009) Multiobjective design of shell-and-tube heat exchangers under uncertainty. Master’s thesis, National Tsing-Hua University, Taiwan

Paul H (1982) An application of geometric programming to heat exchanger design. Comput Ind Eng 6(2):103–114

Paul H (1986) An application of stochastic geometric programming to heat exchanger design. Comput Ind Eng 10(3):253–262

Unuvar A, Kargici S (2004) An approach for the optimum design of heat exchangers. Int J Energy Res 28(15):1379–1392

Onishi VC, Ravagnani MASS, Caballero JA (2013) Mathematical programming model for heat exchanger design through optimization of partial objectives. Energy Convers Manag 74:60–69. https://doi.org/10.1016/j.enconman.2013.05.011

Gonçalves CdO, Costa AL, Bagajewicz MJ (2019) Linear method for the design of shell and tube heat exchangers using the Bell–Delaware method. AIChE J 65(8):1–16

Lemos JC, Costa AL, Bagajewicz MJ (2017) Linear method for the design of shell and tube heat exchangers including fouling modeling. Appl Therm Eng 125:1345–1353

Saldanha WH, Junior PA (2017) General pattern search applied to the optimization of the shell and tube heat exchanger. Int J Adv Eng Res Sci 4(11)

De Jong KA (2006) Evolutionary computation: a unified approach. MIT Press, Cambridge

Bartz-Beielstein T (2006) Experimental research in evolutionary computation: the new experimentalism (Natural computing series). Springer, Berlin

Houck CR, Joines J, Kay MG (1995) A genetic algorithm for function optimization: a matlab implementation. Ncsu-ie tr 95(09):1–10

Acknowledgements

”This study was financed in part by the Coordenação de Aperfeiçãoamento de Pessoal de Nível Superior - Brasil (CAPES) - Finance Code 001”.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Variables related to STHE optimization problems

Appendix: Variables related to STHE optimization problems

The variables used in the related works are presented in Tables 9 and 10, they are: tube layout pattern (\(a_p\)), number of passes (np), length of the tubes (\(L_t\)), wall thickness of the tubes (esp), outer diameter of the tubes (\(d_o\)), inner diameter of tubes (\(d_i\)), baffle spacing (\(L_b\)), baffle cut (bc), tube-to-baffle diametrical clearance (\(\delta _{tb}\)), shell-to-baffle diametrical clearance (\(\delta _{sb}\)), inner diameter of the shell (\(D_s\)), outer diameter of the tube bundle (\(D_{otl}\)), tube pitch (\(P_t\)), number of tubes (\(N_{t}\)), number of baffles (\(N_b\)), number of sealing strips (\(N_{ss}\)), cold side fluid output temperature (\(T_{c,o}\)), angle between two radii intersected at the inside shell wall with the baffle cut (\(\theta _{b}\)), allowed fouling resistance (\(R_{fall}\)), tube material (\(t_{mat}\)), shell head types (\(sh_{types}\)), fluid allocation (\(f_{alocat}\)).

Rights and permissions

About this article

Cite this article

Saldanha, W.H., Arrieta, F.R.P. & Soares, G.L. State-of-the-Art of Research on Optimization of Shell and Tube Heat Exchangers by Methods of Evolutionary Computation. Arch Computat Methods Eng 28, 2761–2783 (2021). https://doi.org/10.1007/s11831-020-09476-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11831-020-09476-4