Abstract

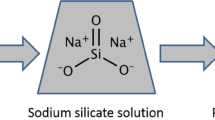

High purity nano silica was synthesized using acid treatment and surface modification from blast-furnace slag generated in the steel industry. Blast-furnace slag was treated with nitric acid to extract high-purity insoluble silica. Nano silica was then produced using filtration and surface modified by cation surfactant-Cetyltrimethyl Ammonium Bromide (CTAB). The Zeta potential of silica was tested under various alkaline conditions. Synthesized silica remained electronegative throughout the pH range tested and the number of hydroxyl groups existing on the silica surface was highest when the pH was 9. The size of silica particles was smallest when the modification temperature was 60 °C. The average size of silica particles modified with 3 wt% CTAB was 107.89 nm, while the average size of unmodified silica was 240.38 nm. After extracting silica, pH of the remaining solution was adjusted by adding CaO and then highpurity calcium nitrate crystals were extracted using solubility difference. It was found experimentally that enriching the solution to a high specific gravity (1.63–1.65) before crystallization is preferable for efficient calcium nitrate recovery.

Similar content being viewed by others

References

Y. Sakamotoa, Y. Tonookab and Y. Yanagisawa, Energy Convers. Manage., 40, 1129 (1999).

J. Maa, D.G. Evansb, R. J. Fullera and D. F. Stewart, Int. J. Production Economics, 76, 293 (2002).

N. Lazaric, P. Mangolte and M. Massué, Research Policy, 32, 1829 (2003).

J. Péra, J. Ambroise and M. Chabannet, Cement and Concrete Research, 29, 171 (1999).

S. Kourounis, S. Tsivilis, P. E. Tsakiridis, G.D. Papadimitriou and Z. Tsibouki, Cement and Concrete Research, 37, 815 (2007).

S. Kumar, R. Kumar, A. Bandopadhyay, T. C. Alex, B. R. Kumar, S.K. Das and S. P. Mehrotra, Cement & Concrete Composites, 30, 679 (2008).

A. Bougara, C. Lynsdale and K. Ezziane, Construction and Building Materials, 23, 542 (2009).

J.H. Johnston, A. J. McFarlane, T. Borrmann and J. Moraes, Current Appl. Phys., 4, 411 (2004).

K.N. Pham, D. Fullston and K. Sagoe-Crentsil, J. Colloid Interf. Sci., 315, 123 (2007).

B. J. Hwang, S.W. Park, D.W. Park, K. J. Oh and S. S. Kim, Korean J. Chem. Eng., 26, 775 (2009).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, SJ., Seo, SG. & Jung, SC. Preparation of high purity nano silica particles from blast-furnace slag. Korean J. Chem. Eng. 27, 1901–1905 (2010). https://doi.org/10.1007/s11814-010-0289-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-010-0289-1