Abstract

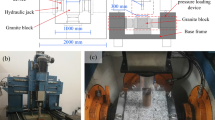

Core discing often occurs in deep rocks under high-stress conditions and has been identified as an important characteristic for deep rock engineering. This paper presents the formation mechanism of core discing firstly. Then, the interaction between diamond drill bits and rock was analyzed based on numerical modeling. A novel drill bit with an inner conical crown for the mitigation of core discing was designed and verified by simulation experiments. The mitigation method was applied in the cavern B1 of CJPL-II and satisfactory results had been achieved. The percentage of core discing had been obviously decreased from 67.8% when drilling with a rectangular crown drill bit, to 26.5% when an inner conical crown drill bit had been adopted. This paper gives full insight into core discing characteristics and provides a new method for core discing mitigation; it will potentially contribute to stress measurement in deep rock engineering.

摘要

岩芯饼化是深部岩石在高应力条件下钻孔时经常发生的现象,是深部岩石工程的一个重要特征。 本文首先介绍了岩芯饼化的形成机理, 基于数值模拟分析了金刚石钻头与岩石之间的相互作用, 通过 数值模拟实验设计并验证了一种可以用于减轻岩芯饼化的新型内圆锥形冠状金刚石钻头。将该方法应 用于CJPL-II的B1 实验室中, 取得了满意的效果, 饼化岩芯所占的百分比从使用矩形冠状钻头钻进 时的67.8%明显降低到采用内圆锥形冠状钻头时的26.5%。本文全面介绍了深部岩石岩芯饼化特征, 并为缓解岩芯饼化现象提供了一种新方法, 这将有助于深部岩石工程中的应力测量。

Similar content being viewed by others

References

HAST N. The state of stress in the upper part of the earth’s crust [J]. Tectonophysics, 1969, 2(1): 5–17. DOI: https://doi.org/10.1016/0013-7952(67)90002-6.

JAEGER J C, COOK N G W. Pinching-off and disking of rocks [J]. Journal of Geophysical Research, 1963, 68(6): 1759–1765. DOI: https://doi.org/10.1029/JZ068i006p01759.

ZHU Wei-shen, LI Guang-yu, WANG Ke-jun. Analyses of disking phenomenon and stress field in the region of an underground powerhouse [J]. Rock Mechanics and Rock Engineering, 1985, 18(1): 1–15. DOI: https://doi.org/10.1007/BF01020412.

BELOV N I, IVANOV V I. Numerical modelling of the stressed state of the foot of a borehole with a study of drill core disking [J]. Journal of Mining Science, 1992, 28(6): 500–503. DOI: https://doi.org/10.1007/BF00734064.

WU S, WU H, KEMENY J. Three-dimensional discrete element method simulation of core disking [J]. Acta Geophysica, 2018, 66(3): 267–282. DOI: https://doi.org/10.1007/s11600-018-0136-z.

CORTHÉSY R, LEITE M H. A strain-softening numerical model of core discing and damage [J]. International Journal of Rock Mechanics & Mining Sciences, 2008, 45(3): 329–350. DOI: https://doi.org/10.1016/j.ijrmms.2007.05.005.

MATSUKI K, KAGA N, YOKOYAMA T, TSUDA N. Determination of three dimensional in situ stress from core discing based on analysis of principal tensile stress [J]. International Journal of Rock Mechanics & Mining Sciences, 2004, 41(7): 1167–1190. DOI: https://doi.org/10.1016/j.ijrmms.2004.05.002.

LIM S S, MARTIN C D. Core disking and its relationship with stress magnitude for Lac du Bonnet granite [J]. International Journal of Rock Mechanics & Mining Sciences, 2010, 47(2): 254–264. DOI: https://doi.org/10.1016/j.ijrmms.2009.11.007.

KANG S S, ISHIGURO Y, OBARA Y. Evaluation of core disking rock stress and tensile strength via the compact conical-ended borehole overcoring technique [J]. International Journal of Rock Mechanics & Mining Sciences, 2006, 43(8): 1226–1240. DOI: https://doi.org/10.1016/j.ijrmms.2006.04.007.

FAIRHURST C. Stress estimation in rock: A brief history and review [J]. International Journal of Rock Mechanics & Mining Sciences, 2003, 40: 957–973. DOI: https://doi.org/10.1016/j.ijrmms.2003.07.002.

LEITE M H, BOIVIN V, CORTHÉSY R. Stress calculation methods for overcoring techniques in heterogeneous rocks [J]. International Journal of Rock Mechanics and Mining Sciences, 2010, 47(7): 1180–1192. DOI: https://doi.org/10.1016/j.ijrmms.2010.06.002.

OUYANG Zhen-hua, LI Chang-hong, XU Wan-cai, LI Hao-jie. Measurements of in situ stress and mining-induced stress in Beiminghe Iron Mine of China [J]. Journal of Central South University of Technology, 2009, 16(1): 85–90. DOI: https://doi.org/10.1007/s11771-009-0014-6.

ZHANG Feng-peng, QIU Zhao-guo, FENG Xia-ting. Non-complete relief method for measuring surface stresses in surrounding rocks [J]. Journal of Central South University, 2014, 21(9): 3665–3673. DOI: https://doi.org/10.1007/s11771-014-2349-x.

LI Shao-jun, FENG Xia-ting, LI Zhan-hai, CHEN Bing-rui, ZHANG Chuan-qing, ZHOU Hui. In situ monitoring of rockburst nucleation and evolution in the deeply buried tunnels of Jinping II hydropower station [J]. Engineering. Geology, 2012, 137: 85–96. DOI: https://doi.org/10.1016/j.enggeo.2012.03.010.

LI Shao-jun, FENG Xia-ting, LI Zhan-hai, ZHANG Chuan-qing, CHEN Bing-rui. Evolution of fractures in the excavation damaged zone of a deeply buried tunnel during TBM construction [J]. International Journal of Rock Mechanics & Mining Sciences, 2012, 55: 125–138. DOI: https://doi.org/10.1016/j.ijrmms.2012.07.004.

LI Zhan-hai, LI Shao-jun, ZHOU Hui, CHEN Bing-rui, ZHANG Chuan-qing. Characteristics and formation mechanism of core discing in deep rock mass [J]. Chinese Journal of Rock Mechanics & Engineering, 2011, 30(11): 2254–2266. DOI: CNKI:SUN:YSLX.0.2011-11-012. (in Chinese)

FENG Xia-ting, XU Hong, QIU Shi-li, LI Shao-jun, YANG Cheng-xiang, GUO Hao-sen, CHENG Yuan, GAO Yao-hui. In situ observation of rock spalling in the deep tunnels of the china jinping underground laboratory (2400 m depth) [J]. Rock Mechanics & Rock Engineering, 2018, 51: 1193–1213. DOI: https://doi.org/10.1007/s00603-017-1387-8.

HU Lei, FENG Xia-ting, XIAO Ya-xun. Characteristics of the microseismicity resulting from the construction of a deeply-buried shaf [J]. Tunnelling and Underground Space Technology, 2019, 85: 114–127. DOI: https://doi.org/10.1016/j.tust.2018.12.016.

LI Shu-sen, NIE De-xin, RE Guang-ming. The fracture mechanism of discal drill core and its influence on characteristic of engineering geology [J]. Advance in Earth Sciences, 2004, 19(S1): 384–387. http://www.cnki.com.cn/Article/CJFDTotal-DXJZ2004S1076.htm. (in Chinese)

SHI Yu-peng, XIA Yi-min, TAN Qing, ZHANG Yi-chao, QIAO Shuo. Distribution of contact loads in crushed zone between tunnel boring machine disc cutter and rock [J]. Journal of Central South University, 2019, 26(9): 2393–2403. DOI: https://doi.org/10.1007/s11771-019-4182-8.

WANG Jia-liang, ZHANG Shao-he. A new diamond bit for extra-hard, compact and nonabrasive rock formation [J]. Journal of Central South University, 2015, 22: 1456–1462. DOI: https://doi.org/10.1007/s11771-015-2663-y.

JIANG An-nan, ZENG Zheng-wen, TANG Chun-an. Three-dimensional numerical test of element safety degree of rock core discing and feed-back analysis of geostresses [J]. Chinese Journal of Rock Mechanics & Engineering, 2010, 29(8): 1610–1617. DOI: CNKI:SUN:YSLX.0.2010-08-015. (in Chinese)

ALEJANO L R, ALFONSO R D, MARÍA V. Plastic radii and longitudinal deformation profiles of tunnels excavated in strain-softening rock masses [J]. Tunnelling and Underground Space Technology Incorporating Trenchless Technology Research, 2012, 30: 169–182. DOI: https://doi.org/10.1016/j.tust.2012.02.017.

LEE Y K, PIETRUSZCZAK S. A new numerical procedure for elasto-plastic analysis of a circular opening excavated in a strain-softening rock mass [J]. Tunnelling and Underground Space Technology, 2008, 23(5): 588–599. DOI: https://doi.org/10.1016/j.tust.2007.11.002.

SI Xue-feng, GONG Feng-qiang. Strength-weakening effect and shear-tension failure mode transformation mechanism of rockburst for fine-grained granite under triaxial unloading compression [J]. International Journal of Rock Mechanics & Mining Science, 2020, 131: 104347. DOI: https://doi.org/10.1016/j.ijrmms.2020.104347.

ZHENG Zhi, FENG Xia-ting, ZHANG Xi-wei, ZHAO Jun, YANG Cheng-xiang. Residual strength characteristics of CJPL marble under true triaxial compression [J]. Rock Mechanics and Rock Engineering, 2019, 52: 1247–1256. DOI: https://doi.org/10.1007/s00603-018-1659-y.

MARTINO J B, CHANDLER N A. Excavation-induced damage studies at the underground research laboratory [J]. International Journal of Rock Mechanics & Mining Sciences, 2004, 41(8): 1413–1426. DOI: https://doi.org/10.1016/j.ijrmms.2004.09.010.

YAN Fei, PAN Peng-zhi, FENG Xia-ting, LI Shao-jun. The continuous-discontinuous cellular automaton method for elastodynamics crack problems [J]. Engineering Fracture Mechanics, 2018, 204: 482–496. DOI: https://doi.org/10.1016/j.engfracmech.2018.10.025.

Author information

Authors and Affiliations

Contributions

The general idea and method of this paper were developed by ZHENG Ming-zong and LI Shao-jun. ZHENG Min-zong was responsible for the full-text writing. YAO Zou and ZHANG Ao-dong provided drill bits and ZHOU Ji-fang provided a site for the field test in this paper. ZHENG Min-zong and XU Ding-ping carried out numerical simulation. LI Shao-jun and XU Ding-ping edited the draft of manuscript. All authors replied to reviewers’ comments and revised the final version.

Corresponding author

Additional information

Conflict of interest

ZHENG Ming-zong, LI Shao-jun, YAO Zou, ZHANG Ao-dong, XU Ding-ping, and ZHOU Ji-fang declare that they have no conflict of interest.

Foundation item: Projects(U1765206, 51979268, 51621006) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Zheng, Mz., Li, Sj., Yao, Z. et al. Core discing characteristics and mitigation approach by a novel developed drill bit in deep rocks. J. Cent. South Univ. Technol. 27, 2822–2833 (2020). https://doi.org/10.1007/s11771-020-4512-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-020-4512-x