Abstract

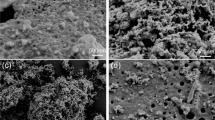

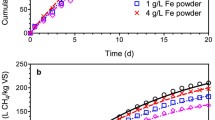

Reduction of Cr(VI) using zero-valent iron (ZVI) could not only decrease the amounts of chemicals used for reduction, but also decrease the discharge of sludge. In order to find a desirable ZVI material, reduction of Cr(VI) with a relative high concentration using different kinds of ZVI powders (mainly carbon differences) including reduced Fe, grey cast iron, pig iron, nodular pig iron was carried out. Parameters such as ZVI dosage, type and size affecting on Cr(VI) reduction were firstly examined and grey cast iron was selected as a preferable reducing material, followed by pig iron. Additionally, it was found that the parameters had significant influences on experimental kinetics. Then, morphology and composition of the sample before and after reaction were characterized by SEM, EPMA and XPS analyses to disclose carbon effect on the reducibility. In order to further interpret reaction mechanism, different reaction models were constructed. It was revealed that not only the carbon content could affect the Cr(VI) reduction, but also the carbon structure had an important effect on its reduction.

摘要

使用零价铁还原 Cr(VI)不仅可以减少还原剂的用量, 还能够减少污泥的排放量。 为找到一种理想的零价铁基材料, 对不同种类的零价铁粉还原相对高浓度的 Cr(VI)进行研究。 这些零价铁粉是还原铁粉、 铸铁粉、 生铁和球磨生铁, 他们的差异性是由碳的不同所致。 首先研究了零价铁粉用量、 种类和粒度大小等参数对Cr(VI)还原的影响, 筛选出了灰铸铁粉是较为理想的还原性铁基材料, 其次是生铁。 另外, 发现这些参数对试验过程动力学有重要的影响。 然后, 采用 SEM、 EPMA 和 XPS 等测试手段, 研究了零价铁粉反应前、 后形貌和组成的变化, 证实了碳差异性对还原性的影响。 为进一步理解其反应机理, 构筑了不同的反应模型。 得出不仅碳的含量对 Cr(VI)还原有影响, 碳的结构对 Cr(VI)还原也有重要的影响。

Similar content being viewed by others

References

HEMAMBIKA B, KANNAN V R. Intrinsic characteristics of Cr6+-resistant bacteria isolated from an electroplating industry polluted soils for plant growth-promoting activities [J]. Applied Biochemistry and Biotechnology, 2012, 167: 1653–1667.

LV Jin-fang, ZHANG Han-ping, TONG Xiong, FAN Chun-lin, YANG Wen-tao, ZHENG Yong-xing. Innovative methodology for recovering titanium and chromium from a raw ilmenite concentrate by magnetic separation after modifying magnetic properties [J]. Journal of Hazardous Materials, 2017, 325: 251–260.

SHANKER A K, CERVANTES C, LOZA-TAVERA H, AVUDAINAYAGAM S. Chromium toxicity in plants [J]. Environment International, 2005, 31: 739–753.

ZHENG Lin, ZHOU Kan, WEN Ben-de, QIN Zhi-rong, XU Rong-nian. Chromium and human health [J]. Trace Elements Science, 2003, 10: 11–15.

MA J, YANG B, BYRNE R H. Determination of nanomolar chromate in drinking water with solid phase extraction and a portable spectrophotometer [J]. Journal of Hazardous Materials, 2012, 219–220: 247–252.

PAPASSIOPI N, VAXEVANIDOU K, CHRISTOU C, KARAGIANNI E, ANTIPAS G S E. Synthesis, characterization and stability of Cr(III) and Fe(III) hydroxides [J]. Journal of Hazardous Materials, 2014, 264: 490–497.

TANG Lin, YANG Gui-de, ZENG Guang-ming, CAI Ye, LI Si-si, ZHOU Yao-yu. Synergistic effect of iron doped ordered mesoporous carbon on adsorption-coupled reduction of hexavalent chromium and the relative mechanism study [J]. Chemical Engineering Journal, 2014, 239: 114–122.

ALVARADO L, TORRES I R, CHEN A. Integration of ion exchange and electrodeionization as a new approach for the continuous treatment of hexavalent chromium wastewater [J]. Separation and Purification Technology, 2013, 105: 55–62.

KANMANI P, ARAVIND J, PRESTON D. Remediation of chromium contaminants using bacteria [J]. International Journal of Environmental Science and Technology, 2012, 9: 183–193.

LI Chun-cheng, XIE Feng-chun, MA Yang, CAI Ting-ting, LI Hai-ying, HUANG Zhi-yuan, YUAN Gao-qing. Multiple heavy metals extraction and recovery from hazardous electroplating sludge waste via ultrasonically enhanced two-stage acid leaching [J]. Journal of Hazardous Materials, 2010, 178: 823–833.

GUAN Xiao-hong, SUN Yuan-kui, QIN He-jie, LI Jin-xiang, LO I M C, HE Di, DONG Hao-ran. The limitations of applying zero-valent iron technology in contaminants sequestration and the corresponding countermeasures: The development in zero-valent iron technology in the last two decades (1994–2014) [J]. Water Research, 2015, 75: 224–248.

HU C Y, LO S L, LIOU Y H, HSU Y W, SHIH K, LIN C J. Hexavalent chromium removal from near natural water by copper–iron bimetallic particles [J]. Water Research, 2010, 44: 3101–3108.

ZHOU Hai-mei, SHEN Yuan-yuan, LV Ping, WANG Jian-ji, FAN Jing. Degradation of 1-butyl-3-methylimidazolium chloride ionic liquid by ultrasound and zero-valent iron/activated carbon [J]. Separation and Purification Technology, 2013, 104: 208–213.

GHEJU M, BALCU I. Hexavalent chromium reduction with scrap iron in continuous-flow system. Part 2: Effect of scrap iron shape and size [J]. Journal of Hazardous Materials, 2010, 182: 484–493.

CHEN S S, HSU B C, HUNG L W. Chromate reduction by waste iron from electroplating wastewater using plug flow reactor [J]. Journal of Hazardous Materials, 2008, 152: 1092–1097.

FU F L, DIONYSIOU D D, LIU H. The use of zero-valent iron for groundwater remediation and wastewater treatment: A review [J]. Journal of Hazardous Materials, 2014, 267: 194–205.

WANG Xiao-song, ZHANG Wei-zheng, GUO Bing-bin, ZHAO Wei-mao. The characteristics of microcrack initiation process in cast iron materials under thermal shock test [J]. Materials Science and Engineering A, 2014, 609: 310–317.

PEVEC M, ODER G, POTRC I, SRAML M. Elevated temperature low cycle fatigue of grey cast iron used for automotive brake discs [J]. Engineering Failure Analysis, 2014, 42: 221–230.

WANG Yu-ping, WANG Lian-jun, PENG Pan-ying, LU Tian-hong. Treatment of naphthalene derivatives with iron-carbon micro-electrolysis [J]. Transactions of Nonferrous Metals Society of China, 2006, 16: 1442–1447.

CHEN S S, CHENG C Y, LI C W, CHAI P H, CHANG Y M. Reduction of chromate from electroplating wastewater from pH 1 to 2 using fluidized zero valent iron process [J]. Journal of Hazardous Materials, 2007, 142: 362–367.

GHEJU M, IOVI A. Kinetics of hexavalent chromium reduction by scrap iron [J]. Journal of Hazardous Materials, 2006, 135: 66–73.

SUTTIPONPARNIT K, JIANG J, SAHU M, SUVACHITTANONT S, CHARINPANITKUL T, BISWAS P. Role of surface area, primary particle size, and crystal phase on titanium dioxide nanoparticle dispersion properties [J]. Nanoscale Research Letter, 2010, 6: 1–8.

MELITAS N, CHUFFE-MOSCOSO, FARRELL J. Kinetics of soluble chromium removal from contaminated water by zerovalent iron media: Corrosion inhibition and passive oxide effects [J]. Environmental Science Technology, 2001, 35: 3948–3953.

ZHANG Yan-hui, CHEN Zhang, LIU Si-qi, XU Yi-jun. Size effect induced activity enhancement and anti-photocorrosion of reduced graphene oxide/ZnO composites for degradation of organic dyes and reduction of Cr(VI) in water [J]. Applied Catalysis B: Environmental, 2013, 140–141: 598–607.

SUN Yuan-kui, GUAN Xiao-hong, WANG Jian-ming, MENG Xiao-guang, XU Chun-hua, ZHOU Guang-ming. Effect of weak magnetic field on arsenate and arsenite removal from water by zerovalent iron: An XAFS investigation [J]. Environmental Science Technology, 2014, 48: 6850–6858.

HOU Mei-fang, WAN Hong-fu, LIU Ting-lin, FAN Yan-ning, LIU Xin-ming, WANG Xu-guang. The effect of different divalent cations on the reduction of hexavalent chromium by zerovalent iron [J] Applied Catalysis B: Environmental, 2008, 84: 170–175.

QIU Yang-shuai, YU Yong-fu, ZHANG Lin-yan, PENG Wei-jun, QIAN Yu-peng. Dispersion and agglomeration mechanism of flaky graphite particles in aqueous solution [J]. Journal of Dispersion Science and Technology, 2017, 38: 796–800.

MENG Sheng, GAO Shi-wei. Formation and interaction of hydrated alkali metal ions at the graphite-water interface [J]. The Journal of Chemical Physics, 2006, 125: 014708.

KAZUHIRO S, NORIAKI O, KEI K, KAZUMI M, HIROFUMI Y. Atomic-resolution imaging of graphite–water interface by frequency modulation atomic force microscopy [J]. Applied Physics Express, 2011, 4: 125102.

CANO E, TORRES C L, BASTIDAS J M. An XPS study of copper corrosion originated by formic acid vapour at 40% and 80% relative humidity [J]. Materials and Corrosion, 2001, 52: 667–676.

ABDEL-SAMAD H, WATSON P R. An XPS study of the adsorption of chromate on goethite (α-FeOOH) [J]. Applied Surface Science, 1997, 108: 371–377.

BIESINGER M C, BROWN C, MYCROFT J R, DAVIDSON R D, MCINTYRE N S. X-ray photoelectron spectroscopy studies of chromium compounds [J]. Surface and Interface Analysis, 2004, 36: 1550–1563.

GALICIA P, BATINA N, GONZALEZ I. The relationship between the surface composition and electrical properties of corrosion films formed on carbon steel in alkaline sour medium: An XPS and EIS study [J]. The Journal of Physical Chemistry B, 2006, 110: 14398–14405.

DESCOSTES M, MERCIER F, THROMAT N, BEAUCAIRE C, GAUTIER-SOYER M. Use of XPS in the determination of chemical environment and oxidation state of iron and sulfur samples: Constitution of a data basis in binding energies for Fe and S reference compounds and applications to the evidence of surface species of an oxidized pyrite in a carbonate medium [J]. Applied Surface Science, 2000, 165: 288–302.

GROSVENOR A P, KOBE B A, BIESINGER M C, MCINTYRE N S. Investigation of multiplet splitting of Fe 2p XPS spectra and bonding in iron compounds [J]. Surface and Interface Analysis, 2004, 36: 1564–1574.

FIUZA A, SILVA A, CARVALHO G, DELAFUENTE A V, DELERUE-MATONS C. Heterogeneous kinetics of the reduction of chromium (VI) by elemental iron [J]. Journal of Hazardous Materials, 2010, 175: 1042–1047.

GHEJU M, IOVI A, BALCU I. Hexavalent chromium reduction with scrap iron in continuous-flow system: Part 1: Effect of feed solution pH [J]. Journal of Hazardous Materials, 2008, 153: 655–662.

GUAN Xiao-hong, DONG Hao-ran, MA Jun, LO I M C, DOU X M. Performance and mechanism of simultaneous removal of chromium and arsenate by Fe(II) from contaminated groundwater [J]. Separation and Purification Technology, 2011, 80: 179–185.

BRANSFIELD S J, CWIERTNY D M, LIVI K, FAIRBROTHER D H. Influence of transition metal additives and temperature on the rate of organohalide reduction by granular iron: Implications for reaction mechanisms [J]. Applied Catalysis B: Environmental, 2007, 76: 348–356.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation item: Project(51604131) supported by the National Natural Science Foundation of China; Project(2017FB084) supported by the Yunnan Province Applied Basic Research, China; Project(KKSY201563041) supported by the Talent & Training Program of Yunnan Province, China; Projects(2017T20090159, 2018T20150055) supported by the Testing and Analyzing Funds of Kunming University of Science and Technology, China

Rights and permissions

About this article

Cite this article

Lv, Jf., Tong, X., Zheng, Yx. et al. Reduction of Cr(VI) with a relative high concentration using different kinds of zero-valent iron powders: Focusing on effect of carbon content and structure on reducibility. J. Cent. South Univ. 25, 2119–2130 (2018). https://doi.org/10.1007/s11771-018-3901-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3901-x