Abstract

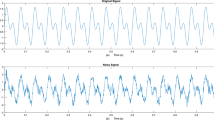

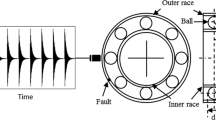

The accurate estimation of the rolling element bearing instantaneous rotational frequency (IRF) is the key capability of the order tracking method based on time-frequency analysis. The rolling element bearing IRF can be accurately estimated according to the instantaneous fault characteristic frequency(IFCF). However, in an environment with a low signal-to-noise ratio (SNR), e.g., an incipient fault or function at a low speed, the signal contains strong background noise that seriously affects the effectiveness of the aforementioned method. An algorithm of signal preprocessing based on empirical mode decomposition (EMD) and wavelet shrinkage was proposed in this work. Compared with EMD denoising by the cross-correlation coefficient and kurtosis(CCK) criterion, the method of EMD soft-thresholding (ST) denoising can ensure the integrity of the signal, improve the SNR, and highlight fault features. The effectiveness of the algorithm for rolling element bearing IRF estimation by EMD ST denoising and the IFCF was validated by both simulated and experimental bearing vibration signals at a low SNR.

Similar content being viewed by others

References

AMIRAT Y, BENBOUZIDA M E H, AL-AHMAR E, BENSAKER B, TURRI S. A brief status on condition Monitoring and fault diagnosis in wind energy conversion systems [J]. Renewable and Sustainable Energy Reviews, 2009, 13(9): 2629–2636.

CHENG W D, ROBERT X G, WANG J J, WANG T Y, WEN W G, LI J Y. Envelope deformation in computed order tracking and error in order analysis [J]. Mechanical System and Signal Processing, 2014, 48(1/2): 92–102.

FYFE K R, MUNCK E D S. Analysis of computed order tracking [J]. Mechanical System And Signal Processing, 1997, 11(2): 187–205.

COATS M D, RANDALL R B. Order-tracking with and without a tacho signal for gear fault diagnostics [C]// Proceedings of Acoustics, Fremantle, Australia: Australian Acoustical Society, 2012: 447–454.

BONNARDOT F, BADAOUI M E, RANDALL R B, DANIERE J, GUILLET F. Use of the acceleration signal of a gearbox in order to perform angular resampling (with limited speed fluctuation) [J]. Mechanical Systems and Signal Processing, 2005, 19(4): 766–785.

COMBET F, GELMAN L. An automated methodology for performing time synchronous averaging of a gearbox signal without speed sensor [J]. Mechanical Systems and Signal Processing, 2007, 21(6): 2590–2606.

COMBET F, ZIMROZ R. A new method for the estimation of the instantaneous speed relative fluctuation in a vibration signal based on the short time scale transform [J]. Mechanical Systems and Signal, 2009, 23(4): 1382–1397.

URBANEK J, BARSZCZ T, ANTONI J. A two-step procedure for estimation of instantaneous rotational speed with large fluctuations [J]. Mechanical Systems and Signal Processing, 2013, 38(1): 96–102.

BOASHASH B. Interpreting and estimating the instantaneous frequency of a signal-Part 1: Fundamentals [J]. Proceedings of the IEEE, 1992, 80(4): 520–538.

BOASHASH B. Interpreting and estimating the instantaneous frequency of a signal-Part 2: Algorithms and applications [J]. Proceedings of the IEEE, 1992, 80(4): 540–568.

GUO Yu, QIN Shu-ren, TANG Bao-ping, JI Yue-bo. Order tracking of rotating machinery based on instantaneous frequency estimation [J]. Chinese Journal of Mechanical Engineering, 2003, 39(3): 32–36. (in Chinese)

ZHAO Xiao-ping, ZHAO Xiu-li, HOU Rong-tao, HENG Yu-hui, YANG Wen-ping. A new method for instantaneous frequency estimation of run-up or run-down vibration signal for rotating machinery [J]. Chinese Journal of Mechanical Engineering, 2011, 47(7): 103–108. (in Chinese)

WANG T Y, LIANG M, LI J Y, CHENG W D. Rolling element bearing fault diagnosis via fault characteristic order (FCO) analysis [J]. Mechanical System and Signal Processing, 2014, 45(1): 139–153.

HUANG N E, ZENG S, LONG S R, WU M C, SHIH H H, ZHENG Q, YEN N C, TUNG C C, LIU H H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis [J]. Proc R Soc Lond A, 1998, 454(1971): 903–995.

SU Wen-sheng, WANG Feng-tao, ZHANG Zhi-xin, GUO Zhenggang, LI Hong-kun. Application of EMD denoising and spectral kurtosis in early fault diagnosis of rolling element bearing [J]. Journal of Vibration and Shock, 2010, 29(3): 18–21. (in Chinese)

TANG Gui-ji, WANG Xiao-long. Fault diagnosis for roller bearings based on EEMD de-noising and 1.5-dimension energy spectrum [J]. Journal of Vibration and Shock, 2014, 33(1): 6–10. (in Chinese)

DAVID L D, IAIN M J. Threshold selection for wavelet shrinkage of noisy data [J]. Engineering in Medicine and Biology Society, IEEE, 1994, 1: A24–A25.

DONOHO D L, JOHNSTONE I. Wavelet shrinkage asymptotic [J]. Journal of Royal Statistical Society, 1995, 57(2): 301–369.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(51275030) supported by the National Natural Science Foundation of China; Project(2016JBM051) supported by the Fundamental Research Funds for the Central Universities, China

Rights and permissions

About this article

Cite this article

Zhao, Dz., Li, Jy., Cheng, Wd. et al. Rolling element bearing instantaneous rotational frequency estimation based on EMD soft-thresholding denoising and instantaneous fault characteristic frequency. J. Cent. South Univ. 23, 1682–1689 (2016). https://doi.org/10.1007/s11771-016-3222-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-016-3222-x