Abstract

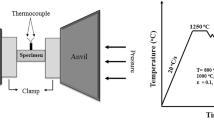

High temperature plastic deformation behavior of non-orientated electrical steel was investigated by Gleeble 1500 thermo-mechanical simulator at strain rate of 0.01−10 s−1 and high temperature of 500–1 200 °C. The stress level factor (a), stress exponent (n), structural factor (A) and activation energy (Q) of high temperature plastic deformation process of non-orientated electrical steel in different temperature ranges were calculated by the Arrhenius model. The results show that, with dynamic elevation of deformation temperature, phase transformation from α-Fe to γ-Fe takes place simultaneously during plastic deformation, dynamic recovery and dynamic recrystallization process, leading to an irregular change of the steady flow stress. For high temperature plastic deformation between 500 and 800°C, the calculated values of a, n, A, and Q are 0.039 0 MPa−1, 7.93, 1.9×1018 s−1, and 334.8 kJ/mol, respectively, and for high temperature plastic deformation between 1 050 and 1 200 °C, the calculated values of a, n, A, and Q are 0.125 8 MPa−1, 5.29, 1.0×1028 s−1, and 769.9 kJ/mol, respectively.

Similar content being viewed by others

References

COLAS R. A model for the hot deformation of the low-carbon steel [J]. Journal Materials Process and Technology, 1996, A62(1/3): 180–184.

XIAO Yu-de, WANG Wei, LI Wen-xian. High temperature deformation behavior and mechanism of spray deposited Al-Fe-V-Si alloy [J]. Trans Nonferrous Met Soc China, 2007, 17(6): 1175–1180.

LIN Qi-quan, PENG Da-shu, ZHANG Hui, LIN Gao-yong. Dynamic and static softening behaviors of 2519 aluminum alloy during multi-stage hot compression deformation [J]. Journal of Central South University: Science and Technology, 2005, 36(2): 183–187. (in Chinese)

WANG Jin, CHEN Jun, ZHAO Zhen, RUAN Xue-yu. Hot deformation behavior and flow stress model of F40MnV steel [J]. Journal of Central South University of Technology, 2007, 14(1): 19–23.

SIDOR Y, KOVAC F. Microstructural aspects of grain growth kinetics in non-oriented electrical steels [J]. Materials Characterization, 2005, 55(1): 1–11.

KOVAC F, DZUBINSKY M, SIDOR Y. Columnar grain growth in non-oriented electrical steels [J]. Journal of Magnetism and Magnetic Materials, 2004, 269(3): 333–340.

PAOLINELLI S C, CUNHA M A D. Effect of stress relief annealing temperature and atmosphere on the magnetic properties of silicon steel [J]. Journal of Magnetism and Magnetic Materials, 2006, 304(2): e599–e601.

CHANG S K. Texture change from primary to secondary recrystallization by hot-band normalizing in grain-oriented silicon steels [J]. Mater Sci Eng A, 2007, A452/453(2): 97–98.

HOUBAERT Y, ROS-YANEZ T, MONSALVE A, LORENZO J B. Texture evolution in experimental grades of high-silicon electrical steels [J]. Physica B, 2006, 384(1/2): 310–312.

POIRIER J P. Hot plastic deformation of crystal [M]. GUAN De-lin, trans. Dalian: Dalian University of Technology Press, 1989: 218–224.

RAO K P, HAWBOLT E B. Development of constitutive relationship using compressing testing of medium carbon steel [J]. Journal of Materials and Process Technology, 1992, 114(3): 116–123.

PETER A L, RICHARD P D. An artificial neural network approach to multiphase continua constitutive modeling [J]. Composites (Part B): Engineering, 2007, 38(7/8): 817–823.

LIN J, DEAN T A. Modelling of microstructure evolution in hot forming using unified constitutive equations [J]. Journal of Materials Processing Technology, 2005, 167(2/3): 354–362.

MCQUEEN J, RYAN N D. Constitutive analysis in hot working [J]. Mater Sci Eng A, 2002, A322(1/2): 43–63.

MA A, ROTERS F, RAABE D. On the consideration of interactions between dislocations and grain boundaries in crystal plasticity finite element modeling—Theory, experiments, and simulations [J]. Acta Material, 2006, 54(8): 2181–2194.

CASTEO-FERNANDEZ F R, SELLAR C M, WHITEMAN J A. Change of stress and microstructure during hot deforming of Al-Mg-1Mn [J]. Material Science and Technology, 1990, 6(5): 453–460.

JONAS J, SELLARS C M, TEGART W J, MC G. Strength and structure under hot working condition [J]. Int Metal Reviews, 1969, 130(14): 1–24.

IMBERT C, RYAN N D, MCQUEEN H J. Hot workability of the three grade of tool steel [J]. Metal Tran A, 1984, 15(10): 1855–1864.

MILOVIC C, MANOJLOVIC D, ANDJELIC M. Hot workability of M2 type high-speed steel [J]. Steel Research, 1992, 63(2): 78–84.

ZHANG Wen-kang, MAO Wen-min, WANG Yi-de, XUE Zhi-yong, BAI Zhi-hao. Influence of hot-rolling parameters on microstructure and magnetic properties of non-oriented electrical steel [J]. Iron and Steel, 2006, 41(4): 77–81. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2005038560) supported by the Postdoctoral Foundation of China; Project(05GK1002-2) supported by Key Program of Hunan Province

Rights and permissions

About this article

Cite this article

Xiao, Yd., Li, M., Wang, W. et al. High temperature plastic deformation behavior of non-oriented electrical steel. J. Cent. South Univ. Technol. 16, 25–31 (2009). https://doi.org/10.1007/s11771-009-0004-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-009-0004-8