Abstract

Mixed oxide ceramics show high potential for widespread utilization due to the transformation toughening effect of these ceramics. During grinding, the stress-induced transformation from the tetragonal to the monoclinic phase of ZrO2 particles ensures a high strength in combination with a high fracture toughness even after processing with unavoidable surface and subsurface damage due to micro-cracks. The thermal impact during grinding can be one of the main limitations of this transformation toughening effect in case of exceeding the temperature of retransformation back to the tetragonal phase. Thus, the technological basis for a reliable grinding process of mixed oxide ceramics requires a fundamental understanding of the grinding temperatures to maintain workpiece quality and strength requirements. This paper presents an analytical method to calculate the maximum grinding temperatures beneath a single abrasive grain and show their effect on the bending strength of ground mixed oxide ceramics as well as on the monoclinic phase content and on the residual stresses.

Similar content being viewed by others

References

Garvie RC, Hannink RH, Pascoe RT (1975) Ceramic steel? Nature 258:703–704

Chevalier J, Gremillard L, Virkar AV, Clarke DR (2009) The tetragonal-monoclinic transformation in Zirconia: lessons learned and future trends. J Am Ceram Soc 92(9):1901–1920

Claussen N (1982) Umwandlungsverstärkte keramische Werkstoffe. Z Werkstofftech 13:138–147

Tönshoff HK, Denkena B (2013) Basics of cutting and abrasive processes. Lecture Notes in Production Engineering, Springer

Rowe WB, Black SCE, Mills B, Qi HS (1996) Analysis of grinding temperatures by energy partitioning. Proc Instn Mech Engrs 210:579–588

Guo C, Wu Y, Varghese V, Malkin S (1999) Temperatures and energy partition for grinding with vitrified CBN wheels. Ann CIRP 48:247–250

Zhu B, Guo C, Sunderland JE, Malkin S (1995) Energy partition to the workpiece for grinding of ceramics. Ann CIRP 44:267–271

Malkin S, Guo C (2007) Thermal analysis of grinding. Ann CIRP 56:760–782

Kohli S, Guo C, Malkin S (1995) Energy partition to the workpiece for grinding with aluminum oxide and CBN abrasive wheels. Trans ASME 117:160–168

Hessert R, Eigenmann B, Vöhringer O, Löhe D (1997) Fracture mechanical evaluation of the effects of grinding residual stresses on bending strength of ceramics. Mater Sci Eng A 234-236:1126–1129

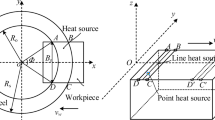

Jaeger JC (1942) Moving sources of heat and the temperature at sliding contacts. J Proc Soc NSW 76:202–224

Surberg CH, Wuthnow H (1996) Rötgenographische analyse der ZrO2-polymorphen an Pulvern. Cfi/Ber DKG 73(11/12):674–677

Jahanmir S, Ramulu M, Philip K (1999) Machining of ceramics and composites. Marcel Dekker

Lierse T (1998) Mechanische und thermische Wirkungen beim Schleifen keramischer Werkstoffe. Dr.-Ing. Dissertation, Hannover

Ramanath S, Shaw MC (1988) Abrasive grain temperature at the beginning of the cut in fine grinding. J Eng Ind 110:15–18

Klocke F, König W (2005) Fertigungsverfahren 2, Schleifen, Honen, Läppen. Springer

Battaglia JL (2008) Heat transfer in materials forming processes. Wiley

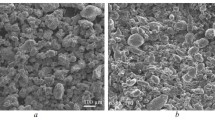

Denkena B, Gottwik L, Grove T, Wippermann A (in press) Material removal mechanisms in grinding of mixed oxide ceramics. Procedia CIRP, 3rd BioManufacturing Conference (CIRP BioM)

Claussen N (1977) Stress-induced transformation of tetragonal ZrO2 particles in ceramic matrices. J Am Ceram Soc 61:85–86

Claussen N (1982) Umwandlungsverstärkte keramische Werkstoffe. Z. Werkstofftech. 13:185–196

Acknowledgements

The authors would like to thank the German Research Foundation (DFG) for its support of the subproject T5 within the Collaborative Research Center 599 “Sustainable bioresorbable and permanent implants of metallic and ceramic materials”.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Denkena, B., Gottwik, L., Grove, T. et al. Temperature and energy partition for grinding of mixed oxide ceramics. Prod. Eng. Res. Devel. 11, 409–417 (2017). https://doi.org/10.1007/s11740-017-0757-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11740-017-0757-0