Abstract

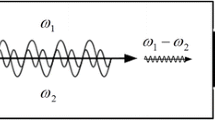

The accuracy of subgrade quality evaluation is important for road safety assessment. Since there is little research work devoted to testing lightweight cellular concrete (LCC) by an ultrasound-based method, the quantitative relation between ultrasonic testing results and the quality of LCC subgrade is not well understood. In this paper, the quality of LCC subgrade was evaluated with respect to compressive strength and crack discrimination. The relation between ultrasonic testing results and LCC quality was explored through indoor tests. Based on the quantitative relation between ultrasonic pulse velocity and compressive strength of LCC, a fitting formula was established. Moreover, after the LCC became cracked, the ultrasonic pulse velocity and ultrasonic pulse amplitude decreased. After determining the lower limiting values of the ultrasonic pulse velocity and ultrasonic pulse amplitude through the statistical data, it could be calculated whether there were cracks in LCC subgrade. The ultrasonic testing results showed that the compressive strength of the LCC subgrade was suitable for purpose and there was no crack in the subgrade. Then core samples were taken from the subgrade. Comparisons between ultrasonic testing results of subgrade and test results of core samples demonstrated a good agreement.

Similar content being viewed by others

References

Ramamurthy K, Nambiar E K K, Ranjani G I S. A classification of studies on properties of foam concrete. Cement and Concrete Composites, 2009, 31(6): 388–396

Ranjani I S, Ramamurthy K. Relative assessment of density and stability of foam produced with four synthetic surfactants. Materials and Structures, 2010, 43(10): 1317–1325

Sayadi A A, Tapia J V, Neitzert T R, Clifton G C. Effects of expanded polystyrene (EPS) particles on fire resistance, thermal conductivity and compressive strength of foamed concrete. Construction & Building Materials, 2016, 112: 716–724

Amran Y H M, Farzadnia N, Ali A A A. Properties and applications of foamed concrete: A review. Construction & Building Materials, 2015, 101(1): 990–1005

Liu X, Sheng K, Li Z, Gan L, Shan H, Hong B. Experimental research on foamed mixture lightweight soil mixed with fly-ash and quicklime as backfill material behind abutments of expressway bridge. Advances in Materials Science and Engineering, 2017, 2017(16): 1–11

Liu X, Ni C, Meng K, Zhang L, Liu D, Sun L. Strengthening mechanism of lightweight cellular concrete filled with fly ash. Construction & Building Materials, 2020, 251: 118954

Jitchaiyaphum K, Sinsiri T, Jaturapitakkul C, Chindaprasirt P. Cellular lightweight concrete containing high-calcium fly ash and natural zeolite. International Journal of Minerals Metallurgy and Materials, 2013, 20(5): 462–471

Bing C, Zhen W, Ning L. Experimental research on properties of high-strength foamed concrete. Journal of Materials in Civil Engineering, 2012, 24(1): 113–118

Liu C, Luo J, Li Q, Gao S, Su D, Zhang J, Chen S. Calcination of green high-belite sulphoaluminate cement (GHSC) and performance optimizations of GHSC-based foamed concrete. Materials & Design, 2019, 182: 107986

Sari K A M, Sani A R M. Applications of foamed lightweight concrete. Matec Web of Conferences, 2017, 97: 01097

Liu X, Ni C, Ji H, Tan S, Hong B. Construction techniques and quality test and evaluation of lightweight cellular concrete mixed with fly ash as subgrade material. Advances in Materials Science and Engineering, 2019, 2019(4): 1–12

Kadela M, Kozlowski M, Kukielka A. Application of foamed concrete in road pavement—Weak soil system. Procedia Engineering, 2017, 193: 439–446

Huang J, Su Q, Zhao W, Li T, Zhang X. Experimental study on use of lightweight foam concrete as subgrade bed filler of ballastless track. Construction & Building Materials, 2017, 149: 911–920

Liu X, Ni C, Zhang L, Sheng K, Hong B. Durability assessment of lightweight cellular concrete in subgrade by the method of analytic hierarchy process combined with fuzzy comprehensive evaluation. Mathematical Problems in Engineering, 2019, 2019: 1–10

Park D W, Vo H V. Evaluation of air-foam stabilized soil of dredged soil waste as a pavement subgrade layer. KSCE Journal of Civil Engineering, 2015, 19(7): 2091–2097

Sychova A, Solomahin A, Hitrov A. The increase of the durability and geoprotective properties of the railway subgrade. Procedia Engineering, 2017, 189: 688–694

Qasrawi H Y. Concrete strength by combined nondestructive methods simply and reliably predicted. Cement and Concrete Research, 2000, 30(5): 739–746

Liu L, Miramini S, Hajimohammadi A. Characterising fundamental properties of foam concrete with a non-destructive technique. Nondestructive Testing and Evaluation, 2019, 34(1): 54–69

Yoo K S, Kim J, Kim I B. Ultrasonic pulses characteristics in lightweight fine aggregate concrete under various load histories. Journal of the Korean Recycled Construction Resources Institute., 2014, 2(3): 209–216

He M, Yang T. Non-destructive evaluation of the bending-fatigue damage in carbon-fiber-composite laminates based on ultrasonic wave propagation. Journal of Testing and Evaluation, 2018, 46(2): 647–655

Demirboga R, Turkmen I, Karakoc M B. Relationship between ultrasonic velocity and compressive strength for high-volume mineral-admixtured concrete. Cement and Concrete Research, 2004, 34(12): 2329–2336

Haach V G, Juliani L M, Roz M R D. Ultrasonic evaluation of mechanical properties of concretes produced with high early strength cement. Construction & Building Materials, 2015, 96: 1–10

Payan C, Quiviger A, Garnier V, Chaix J F, Salin J. Applying diffuse ultrasound under dynamic loading to improve closed crack characterization in concrete. Journal of the Acoustical Society of America, 2013, 134(2): 211–216

Chai H K, Momoki S, Kobayashi Y, Aggelis D G, Shiotani T. Tomographic reconstruction for concrete using attenuation of ultrasound. NDT & E International, 2011, 44(2): 206–215

Hamid R, Yusof K M, Zain M F M. A combined ultrasound method applied to high performance concrete with silica fume. Construction & Building Materials, 2010, 24(1): 94–98

Gul R, Demirboga R, Guvercin T. Compressive strength and ultrasound pulse velocity of mineral admixtured mortars. Indian Journal of Engineering and Materials Sciences, 2006, 13(1): 18–24

Nogueira C L, Rens K L. Experimental analysis of cement-based materials under shear stress. Construction & Building Materials, 2018, 170: 392–401

Xu S, Suorineni F T, Li K, Li Y. Evaluation of the strength and ultrasonic properties of foam-cemented paste backfill. International Journal of Mining, Reclamation and Environment, 2017, 31(8): 544–557

Yilmaz T, Ercikdi B, Karaman K, Külekçi G. Assessment of strength properties of cemented paste backfill by ultrasonic pulse velocity test. Ultrasonics, 2014, 54(5): 1386–1394

Liu X, Sun D, Liu D, Meng K, Ni C, Shao Z, Sun L. Simulation of ultrasonic propagation in porous cellular concrete materials. Construction & Building Materials, 2021, 285: 122852

Pu S, Hong B, Liu X, Xu F, Shan H. Detection technology of foamed mixture lightweight soil embankment based on ultrasonic wave transmission method. Advances in Materials Science and Engineering, 2019, 2019: 1–15

Acknowledgements

This study was funded by the National Natural Science Foundation of China (Grant No. 51609071), the Fundamental Research Funds for the Central Universities (Nos. B200202087, B200204032).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, X., Sun, D., Liao, J. et al. Quality evaluation of lightweight cellular concrete by an ultrasound-based method. Front. Struct. Civ. Eng. 16, 1170–1182 (2022). https://doi.org/10.1007/s11709-022-0874-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-022-0874-5