Abstract

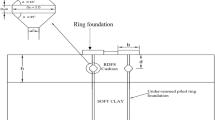

This study investigated the use of recycled tire-derived aggregate (TDA) mixed with kaolin as a method of increasing the ultimate bearing capacity (UBC) of a strip footing. Thirteen 1g physical modeling tests were prepared in a rigid box of 0.6 m × 0.9 m in plan and 0.6 m in height. During sample preparation, 0%, 20%, 40%, or 60% (by weight) of powdery, shredded, small-sized granular (G 1–4 mm) or large-sized granular (G 5–8 mm) TDA was mixed with the kaolin. A strip footing was then placed on the stabilized kaolin and was caused to fail under stress-controlled conditions to determine the UBC. A rigorous 3D finite element analysis was developed in Optum G-3 to determine the UBC values based on the experimental test results. The experimental results showed that, except for the 20% powdery TDA, the TDA showed an increase in the UBC of the strip footing. When kaolin mixed with 20% G (5–8 mm), the UBC showed a threefold increase over that for the unreinforced case. The test with 20% G (1–4 mm) recorded the highest subgrade modulus. It was observed that the UBC calculated using finite element modeling overestimated the experimental UBC by an average of 9%.

Similar content being viewed by others

References

Halder K, Chakraborty D. Probabilistic bearing capacity of strip footing on reinforced anisotropic soil slope. Geomechanics and Engineering, 2020, 23(1): 15–30

EuroSoilStab. Design Guide Soft Soil Stabilisation. Berkshire: IHS BRE Press, 2002

Rashid A S A, Bunawan A R, Said K N M. The deep mixing method: bearing capacity studies. Geotechnical and Geological Engineering, 2017, 35(4): 1271–1298

Dehghanbanadaki A, Ahmad K, Ali N. Influence of natural fillers on shear strength of cement treated peat. Gradevinar, 2013, 65(7): 633–640

Dehghanbanadaki A, Ahmad K, Ali N. Experimental investigations on ultimate bearing capacity of peat stabilized by a group of soil-cement column: Acomparative study. Acta Geotechnica, 2016, 11(2): 295–307

CDIT (Coastal Development Institute of Technology). The Deep Mixing Method—Principle, Design and Construction. Florida: CRC Press, 2002

Li B, Chi Y, Xu L, Shi Y, Li C. Experimental investigation on the flexural behavior of steel-polypropylene hybrid fiber reinforced concrete. Construction & Building Materials, 2018, 191: 80–94

Shishegaran A, Daneshpajoh F, Taghavizade H, Mirvalad S. Developing conductive concrete containing wire rope and steel powder wastes for route deicing. Construction & Building Materials, 2020, 232: 117184

Zhong H, Poon E W, Chen K, Zhang M. Engineering properties of crumb rubber alkali-activated mortar reinforced with recycled steel fibers. Journal of Cleaner Production, 2019, 238: 117950

Amiri S T, Dehghanbanadaki A, Nazir R, Motamedi S. Unit composite friction coefficient of model pile floated in kaolin clay reinforced by recycled crushed glass under uplift loading. Transportation Geotechnics, 2020, 22: 100313

AlKhatib A, Maslehuddin M, Al-Dulaijan S U. Development of high performance concrete using industrial waste materials and nano-silica. Journal of Materials Research and Technology, 2020, 9(3): 6696–6711

Sharma K, Kumar A. Utilization of industrial waste based geopolymers as a soil stabilizer—A review. Innovative Infrastructure Solutions, 2020, 5(3): 1–20

Djadouni H, Trouzine H, Gomes Correia A, Miranda T F S. 2D numerical analysis of a cantilever retaining wall backfilled with sand-tire chips mixtures. European Journal of Environmental and Civil Engineering, 2021, 25(6): 1119–1135

CWA 14243. Post-consumer Tyre Materials and Applications. CEN, 2002

Hazarika H, Pasha S M K, Ishibashi I, Yoshimoto N, Kinoshita T, Endo S, Karmokar A K, Hitosugi T. Tire-chip reinforced foundation as liquefaction countermeasure for residential buildings. Soil and Foundation, 2020, 60(2): 315–326

Tajabadipour M, Dehghani M, Kalantari B, Lajevardi S H. Laboratory pullout investigation for evaluate feasibility use of scrap tire as reinforcement element in mechanically stabilized earth walls. Journal of Cleaner Production, 2019, 237: 117726

Mahgoub A, El Naggar H. Shallow foundations on lightweight TDA backfill: Field tests and 3D numerical modelling. Computers and Geotechnics, 2020, 126: 103761

Khan B J, Ahmad I, Nasir H, Abdullah A, Gohar Q K. Shear strength and pull-out response of tire shred-sand mixture reinforced with deformed steel bars. Advances in Civil Engineering, 2020, 2020: 1–15

Koohmishi M, Azarhoosh A. Degradation of crumb rubber modified railway ballast under impact loading considering aggregate gradation and rubber size. Canadian Geotechnical Journal, 2021, 58(3): 1–13

Yang Z, Yue Z, Tai B. Investigation of the deformation and strength properties of fouled graded macadam materials in heavy-haul railway subgrade beds. Construction & Building Materials, 2021, 273: 121778

Ahn I S, Cheng L. Seismic analysis of semi-gravity RC cantilever retaining wall with TDA backfill. Frontiers of Structural and Civil Engineering, 2017, 11(4): 455–469

Anastasiadis A, Senetakis K, Pitilakis K. Small-strain shear modulus and damping ratio of sand-rubber and gravel-rubber mixtures. Geotechnical and Geological Engineering, 2012, 30(2): 363–382

Rios S, Kowalska M, da Fonseca A V. Cyclic and dynamic behavior of sand-rubber and clay-rubber mixtures. Geotechnical and Geological Engineering, 2021, 39(5): 1–19

Reddy S B, Krishna A M, Reddy K R. Sustainable utilization of scrap tire derived geomaterials for geotechnical applications. Indian Geotechnical Journal, 2018, 48(2): 251–266

Ghazavi M, Sakhi M A. Influence of optimized tire shreds on shear strength parameters of sand. International Journal of Geomechanics, 2005, 5(1): 58–65

Sheikh M N, Mashiri M S, Vinod J S, Tsang H H. Shear and Compressibility behaviour of sand-tire crumb mixtures. Journal of Materials in Civil Engineering, 2013, 25(10): 1366–1374

Ghaaowd I, McCartney J S, Thielmann S S, Sanders M J, Fox P J. Shearing behavior of tire-derived aggregate with large particle size. I: Internal and concrete interface direct shear. Journal of Geotechnical and Geoenvironmental Engineering, 2017, 143(10): 04017078

Yi Y, Kang C, Bayat A. Predicting one-dimensional compression of tire derived aggregate using a simple method. Soil and Foundation, 2019, 59(5): 1292–1301

Bekhiti M, Trouzine H, Rabehi M. Influence of waste tire rubber fibers on swelling behavior, unconfined compressive strength and ductility of cement stabilized bentonite clay soil. Construction & Building Materials, 2019, 208: 304–313

Gill G, Mittal R K, Dandautiya R. Pressure settlement behaviour of strip footing resting on unreinforced and tire chips reinforced copper slag. KSCE Journal of Civil Engineering, 2021, 25(1): 92–106

Bandyopadhyay S, Sengupta A, Reddy G R. Performance of sand and shredded rubber tire mixture as a natural base isolator for earthquake protection. Earthquake Engineering and Engineering Vibration, 2015, 14(4): 683–693

Hataf N, Rahimi M M. Experimental investigation of bearing capacity of sand reinforced with randomly distributed tire shreds. Construction & Building Materials, 2006, 20(10): 910–916

Mittal R K, Gill G. Pressure settlement behaviour of strip footing resting on tire-chip reinforced sand. International Journal of Geotechnical Engineering, 2020, 14(2): 162–168

Shishegaran A, Khalili M R, Karami B, Rabczuk T, Shishegaran A. Computational predictions for estimating the maximum deflection of reinforced concrete panels subjected to the blast load. International Journal of Impact Engineering, 2020, 139: 103527

Shishegaran A, Karami B, Rabczuk T, Shishegaran A, Naghsh M A, Khani M M. Performance of fixed beam without interacting bars. Frontiers of Structural and Civil Engineering, 2020, 14(5): 1180–1195

Shishegaran A, Varaee H, Rabczuk T, Shishegaran G. High correlated variables creator machine: Prediction of the compressive strength of concrete. Computers & Structures, 2021, 247: 106479

Shishegaran A, Saeedi M, Mirvalad S, Korayem A H. The mechanical strength of the artificial stones, containing the travertine wastes and sand. Journal of Materials Research and Technology, 2021, 11: 1688–1709

Naghsh M A, Shishegaran A, Karami B, Rabczuk T, Shishegaran A, Taghavizadeh H, Moradi M. An innovative model for predicting the displacement and rotation of column-tree moment connection under fire. Frontiers of Structural and Civil Engineering, 2021, 15(1): 1–19

Shishegaran A, Ghasemi M R, Varaee H. Performance of a novel bent-up bars system not interacting with concrete. Frontiers of Structural and Civil Engineering, 2019, 13(6): 1301–1315

Es-Haghi M S, Shishegaran A, Rabczuk T. Evaluation of a novel Asymmetric Genetic Algorithm to optimize the structural design of 3D regular and irregular steel frames. Frontiers of Structural and Civil Engineering, 2020, 14(5): 1110–1130

Mortazavi B, Podryabinkin E V, Roche S, Rabczuk T, Zhuang X, Shapeev A V. Machine-learning interatomic potentials enable first-principles multiscale modeling of lattice thermal conductivity in graphene/borophene heterostructures. Materials Horizons, 2020, 7(9): 2359–2367

Ren H, Zhuang X, Rabczuk T. A higher order nonlocal operator method for solving partial differential equations. Computer Methods in Applied Mechanics and Engineering, 2020, 367: 113132

Ren H L, Zhuang X Y, Anitescu C, Rabczuk T. An explicit phase field method for brittle dynamic fracture. Computers & Structures, 2019, 217: 45–56

Potts D M, Zdravković L, Addenbrooke T I, Higgins K G, Kovačević N. Finite Element Analysis in Geotechnical Engineering: Application (Vol. 2). London: Thomas Telford, 2001

Dehghanbanadaki A, Motamedi S, Ahmad K. FE-based modelling of stabilized fibrous peat by end-bearing cement deep mixing columns. Geomechanics and Engineering, 2020, 20(1): 75–86

Majumder M, Chakraborty D. Bearing and uplift capacities of under-reamed piles in soft clay underlaid by stiff clay using lower-bound finite element limit analysis. Frontiers of Structural and Civil Engineering, 2021, 15(2): 1–15

Arefnia A, Momeni E, Armaghni D J, Kassim K A, Ahmad K. Effect of tire derived aggregate on maximum Dry density of Kaolin. Jurnal Teknologi, 2013, 66(1): 19–23

Arefnia A, Dehghanbanadaki A, Kassim K A, Ahmad K. Stabilization of backfill using TDA material under a footing close to retaining wall. Geomechanics and Engineering, 2020, 22(3): 197–206

Prandtl L. On the penetration resistance of plastic building materials and the strength of cutting edges. Journal for Applied Mathematics and Mechanics, 1921, 1(1): 15–20

BS 1377-1. Methods of Test for Soils for Civil Engineering Purposes Part 1: General Requirements and Sample Preparation. London: British Standards Institute, 1990

Jafari M K, Shafiee A. Mechanical behavior of compacted composite clays. Canadian Geotechnical Journal, 2004, 41(6): 1152–1167

Terzaghi K. Evaluation of coefficients of subgrade reaction. Geotechnique, 1955, 5(4): 297–326

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arefnia, A., Dehghanbanadaki, A. & Kassim, K.A. Ultimate bearing capacity of strip footing resting on clay soil mixed with tire-derived aggregates. Front. Struct. Civ. Eng. 15, 1016–1024 (2021). https://doi.org/10.1007/s11709-021-0751-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-021-0751-7