Abstract

Diffusion of oxygen in the ash layer usually dominated the combustion of oil shale semicoke particles due to the high ash content. Thus, effective diffusivity of oxygen in the ash layer was a crucial parameter worthy of careful investigation. In this paper, the effective diffusivity of oxygen in the ash layer of Huadian oil shale semicoke was measured directly using an improved Wicke-Kallenbach diffusion apparatus. The experimental results showed that higher temperature would lead to a higher effective diffusivity and a thicker ash layer had the negative effect. Especially, the effective diffusivity along the direction perpendicular to bedding planes was much lower than that along the direction parallel to bedding planes. In addition, an effective diffusivity model was developed, which could be used to describe the mass transfer of oxygen in the ash layer of oil shale semicoke.

Similar content being viewed by others

References

Strizhakova Y A, Usova T V. Current trends in the pyrolysis of oil shale: a review. Solid Fuel Chemistry, 2008, 42(4): 197–201

Kok M V. Oil shale: pyrolysis, combustion, and environment: a review. Energy Sources, 2002, 24(2): 135–143

Kuang W, Lu M, Yeboah I, Qian G, Duan X, Yang J, Chen D, Zhou X. A comprehensive kinetics study on non-isothermal pyrolysis of kerogen from green river oil shale. Chemical Engineering Journal, 2019, 377: 120275

Tian Y, Li M, Lai D, Chen Z, Gao S, Xu G. Characteristics of oil shale pyrolysis in a two-stage fluidized bed. Chinese Journal of Chemical Engineering, 2018, 26(2): 407–414

Han X, Kulaots I, Jiang X, Suuberg E. Review of oil shale semicoke and its combustion utilization. Fuel, 2014, 126(12): 143–161

Yang Y, Lu X, Wang Q, Mei L, Song D, Hong Y. Experimental study on combustion of low calorific oil shale semicoke in fluidized bed system. Energy & Fuels, 2016, 30(11): 9882–9890

Qin H, Sun B, Wang Q, Zhou M, Liu H, Li S. Analysis on influence factors of the characteristic of pore structure during combustion of oil shale semi-coke. Proceedings of the CSEE, 2008, 28(35): 14–20 (in Chinese)

Wang X, Wang J, Qian J, Zhu Y. Diffusion effects in the ash layer of the oil shale char combustion. Acta Petrolei Sinica (Petroleum Processing Section), 1987, 3(4): 4–11

Yang Y, Wang Q, Lu X, Li J, Liu Z. Combustion behaviors and pollutant emission characteristics of low calorific oil shale and its semi-coke in a lab-scale fluidized bed combustor. Applied Energy, 2018, 211: 631–638

Mu M, Han X, Chen B, Jiang X. Oxidation characteristics of the semicoke from the retorting of oil shale and wheat straw blends in different atmospheres. Oil Shale, 2019, 36(1): 43–61

Yörük C R, Meriste T, Sener S, Kuusik R, Trikkel A. Thermogravimetric analysis and process simulation of oxy-fuel combustion of blended fuels including oil shale, semicoke, and biomass. International Journal of Energy Research, 2018, 42(6): 2213–2224

Wang P, Wang C, Du Y, Feng Q, Wang Z, Yao W, Liu J, Zhang J, Che D. Experiments and simulation on co-combustion of semi-coke and coal in a full-scale tangentially fired utility boiler. Energy & Fuels, 2019, 33(4): 3012–3027

Wang J, Wang X. A study of the combustion reaction model of oil shale particles. Acta Petrolei Sinica (Petroleum Processing Section), 1987, 3(3): 1–9

Huang Y, Zhang M, Lyu J, Yang H. Modeling study of combustion process of oil shale semicoke in a circulating fluidized bed boiler. Carbon Resources Conversion, 2018, 1(3): 273–278

Han X, Jiang X, Yan J, Liu J. Effects of retorting factors on combustion properties of shale char. 2. porestructure. Energy & Fuels, 2011, 25(1): 97–102

Bai J, Wang Q, Jiao G. Study on the pore structure of oil shale during low-temperature pyrolysis. Energy Procedia, 2012, 17(1): 1689–1696

Tiwari P, Deo M, Lin C L, Miller J D. Characterization of oil shale pore structure before and after pyrolysis by using X-ray micro CT. Fuel, 2013, 107(9): 547–554

Sun W, Chen S, Xu M, Wei Y, Fan T, Guo J. The diffusion of molecules inside porous materials with bidisperse pore structures. Chemical Engineering Journal, 2019, 365: 201–219

Le Blévec J M, Barthel E, Briens C. Measurement of volatile diffusivity in polymer particles. Chemical Engineering & Processing Process Intensification, 2000, 39(4): 315–322

Zheng Y, Wang Q, Yang C, Qiu T. Experimental study on mass transport mechanism in poly (styrene-co-divinylbenzene) micro-spheres with hierarchical pore structure. Chemical Engineering and Processing, 2019, 139: 183–192

Wheeler A. Reaction rates and selectivity in catalyst pores. Advances in Catalysis, 1951, 3(6): 249–327

Mota O D S, Campos J B L. Combustion of coke with high ash content in fluidised beds. Chemical Engineering Science, 1995, 50 (3): 433–439

Laurendeau N M. Heterogeneous kinetics of coal char gasification and combustion. Progress in Energy and Combustion Science, 1978, 4(4): 221–270

Sun J K, Hurt R H. Mechanisms of extinction and near-extinction in pulverized solid fuel combustion. Proceedings of the Combustion Institute, 2000, 28(2): 2205–2213

Wakao N, Smith J M. Diffusion in catalyst pellets. Chemical Engineering Science, 1962, 17(11): 825–834

Johnson M F L, Stewart W E. Pore structure and gaseous diffusion in solid catalysts. Journal of Catalysis, 1965, 4(2): 248–252

Fu W B, Zhang B L. Experimental determination of the equivalent mass diffusivity for a porous coal-ash particle. Journal of Combustionence & Technology, 1995, 101(3): 371–377 (in Chinese)

Yan J H, Ni M J, Zhang H T, Cen K F. Gas diffsuion through the ash layer of coal particle. Journal of Engineering Thermophysics, 1994, 15(3): 341–344 (in Chinese)

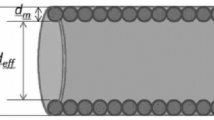

Liu J, Yan J, Han X, Jiang X. Study on the anisotropy of mass transfer for oxygen in the ash layer of shale char particles. Energy & Fuels, 2010, 24(6): 3488–3497

Yang Y, Lu X, Wang Q, Song D, Chen Y, Hong Y. Study on the anisotropy of mass transfer for oxygen in the ash layer of extremely low calorific oil shale semi-coke. Applied Thermal Engineering, 2018, 128: 1494–1501

Wicke E, Kallenbach R. The surface diffusion of carbon dioxide in active carbons. Colloid Journal, 1941, 97(2): 135–151 (in German)

Cao L, He R. Gas diffusion in fractal porous media. Combustion Science and Technology, 2010, 182(7): 822–841

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. U1810126).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Huang, Y., Li, Y., Zhang, M. et al. Effective diffusivity of oxygen in the ash layer of Huadian oil shale semicoke. Front. Energy 15, 320–327 (2021). https://doi.org/10.1007/s11708-020-0674-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11708-020-0674-3