Abstract

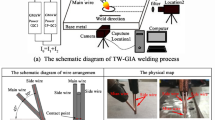

Research on regularity of indirect arc shapes change with variation of applied magnetic field is studied. Results show that indirect arc would be elongated or compressed in XOZ plane with variation of applied transverse magnetic field’s direction and intensity, while the indirect arc would be deflected with the application of longitude magnetic field in YOZ plane, and the deflection degree and direction will be also changed by the variation of longitude magnetic field’s intensity and direction. It is considered that change of arc shapes is caused by variation of arc forces. The influence of Ampere force on indirect arc deformation and deflection is analyzed in this paper.

Similar content being viewed by others

References

Cao M Q, Zou Z D. Electric arc shape of twin-wire indirect arc welding. Transactions of the China Welding Institution, 2006, 27(12): 50–52 (in Chinese)

Zhang S-S, Cao M-Q, Wu D-T, et al. Effects of process parameters on arc shape and penetration in twin-wire indirect arc welding. Frontiers of Materials Science in China, 2009, 3(2): 212–217

Karadeniz E, Ozsarac U, Yildiz C. The effect of process parameters on penetration in gas metal arc welding process. Materials & Design, 2007, 28(2): 649–656

Suban M. Tuek. J. Dependence of melting rate in MIG/MAG welding on the type of shielding gas used. Journal of Materials Processing Technology, 2001, 119(1–3): 185–192

Tanaka M, Tashiro S, Ushio M, et al. CO2-shielded arc as a high-intensity heat source. Vacuum, 2006, 80(11–12): 1195–1198

Lu S. Marangoni convection and weld shape variation in Ar-O2 and Ar-CO2 shielded GTA welding. Materials Science and Engineering A, 2004, 380(1–2): 290–297

Guo Z Y. The temperature and flow field of a free burning arc deflected by a transverse magnetic field. International Journal of Heat and Mass Transfer, 1984, 27(3): 383–390

Li M J, Tamura T, Omura N, et al. Effects of magnetic field and electric current on the solidification of AZ91D magnesium alloys using an electromagnetic vibration technique. Journal of Alloys and Compounds, 2009, 487(1–2): 187–193

Hu J, Tsai H L. Heat and mass transfer in gas metal arc welding. Part II: The metal. International Journal of Heat and Mass Transfer, 2007, 50(5–6): 808–820

Ando K, Hasegawa M. The Phenomenon of Welding Arc. Publishing Company of Mechanical Industry, 1978, 56–58

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, SS., Zou, ZD. Effects of applied magnetic field on twin-wire indirect arc shapes. Front. Mater. Sci. China 4, 321–324 (2010). https://doi.org/10.1007/s11706-010-0096-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11706-010-0096-y