Abstract

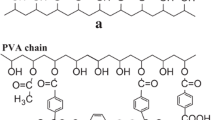

The emergence of vitrimer, a new class of polymer materials can address the problem of recyclability, reprocess ability and recyclability of thermosetting plastics. Rosin, a natural product, is an ideal raw material for the preparation of polymers in a more sustainable way. Nevertheless, due to the huge steric hindrance caused by the hydrogenated phenanthrene ring structure, the cross-link density of materials is frequently lowered. In this study, hydrogenated rosin was adopted for preparing hydrogenated rosin side-chain type diacids, which were reacted with mixed epoxy to obtain rosin side-chain type vitrimers. It was completely characterized by differential scanning calorimetry test, thermogravimetric analysis, shape memory test and self-healing test. The prepared vitrimers exhibited good self-healing properties, excellent heat resistance (Td = 352 °C) as well as high mechanical properties (tensile strength of 46.75 MPa). The tricyclic diterpene structure of rosin was introduced into the side chain in order to avoid the reduction of cross-link density resulting from the huge steric hindrance of the rigid tricyclic hydrophenylene skeleton. Vitrimers can undergo dynamic transesterification reaction without external catalysts due to the autocatalytic effect of tertiary amines from epoxy. Moreover, our work expanded the application field of rosin, increased the added value of rosin, and provided a novel method for preparing rosin-based vitrimers with ideal properties.

Similar content being viewed by others

References

Hirano K, Asami M. Phenolic resins-100 years of progress and their future. Reactive & Functional Polymers, 2013, 73(2): 256–269

Zheng J, Png Z M, Ng S H, Tham G X, Ye E, Goh S S, Loh X J, Li Z. Vitrimers: current research trends and their emerging applications. Materials Today, 2021, 51: 586–625

Chakma P, Konkolewicz D. Dynamic covalent bonds in polymeric materials. Angewandte Chemie International Edition, 2019, 58(29): 9682–9695

Montarnal D, Capelot M, Tournilhac F, Leibler L. Silica-like malleable materials from permanent organic networks. Science, 2011, 334(6058): 965–968

Porath L E, Evans C M. Importance of broad temperature windows and multiple rheological approaches for probing viscoelasticity and entropic elasticity in vitrimers. Macromolecules, 2021, 54(10): 4782–4791

Meng F, Saed M O, Terentjev E M. Elasticity and relaxation in full and partial vitrimer networks. Macromolecules, 2019, 52(19): 7423–7429

Lessard J J, Scheutz G M, Sung S H, Lantz K A, Epps T H III, Sumerlin B S. Block copolymer vitrimers. Journal of the American Chemical Society, 2020, 142(1): 283–289

Ling F, Liu Z, Chen M, Wang H, Zhu Y, Ma C, Wu J, Huang G. Compatibility driven self-strengthening during the radical-responsive remolding process of poly-isoprene vitrimers. Journal of Materials Chemistry A: Materials for Energy and Sustainability, 2019, 7(44): 25324–25332

Yu K, Xin A, Wang Q. Mechanics of self-healing polymer networks crosslinked by dynamic bonds. Journal of the Mechanics and Physics of Solids, 2018, 121: 409–431

Yu L, Zhu C, Sun X, Salter J, Wu H, Jin Y, Zhang W, Long R. Rapid fabrication of malleable fiber reinforced composites with vitrimer powder. ACS Applied Polymer Materials, 2019, 1(9): 2535–2542

Yang H, He C, Russell T P, Wang D. Epoxy-polyhedral oligomeric silsesquioxanes (POSS) nanocomposite vitrimers with high strength, toughness, and efficient relaxation. Giant, 2020, 4: 100035

Hubbard A M, Ren Y, Konkolewicz D, Sarvestani A, Picu C R, Kedziora G S, Roy A, Varshney V, Nepal D. Vitrimer transition temperature identification: coupling various thermomechanical methodologies. ACS Applied Polymer Materials, 2021, 3(4): 1756–1766

Liu T, Hao C, Shao L, Kuang W, Cosimbescu L, Simmons K L, Zhang J. Carbon fiber reinforced epoxy vitrimer: robust mechanical performance and facile hydrothermal decomposition in pure water. Macromolecular Rapid Communications, 2021, 42(3): e2000458

Kassem S, Adam K, Louis C, Matthew A, Abdulla W, Howard A, Yehuda S. The putative adverse effects of bisphenol A on autoimmune diseases. Endocrine, Metabolic & Immune Disorders Drug Targets, 2021, 21: 2212–3873

Sun H, Liu Z, Liu K, Gibril M E, Kong F, Wang S. Lignin-based superhydrophobic melamine resin sponges and their application in oil/water separation. Industrial Crops and Products, 2021, 170: 113798

Xu C, Qu C, Lu M, Meng U, Chen B, Jiao E, Zhang E, Wu K, Shi J. Effect of modified bamboo lignin replacing part of C5 petroleum resin on properties of polyurethane/polysiloxane pressure-sensitive adhesive and its application on the wood substrate. Journal of Colloid and Interface Science, 2021, 602: 394–405

Zhang Y, Huang R, Yu J, Jiang X. Facile fabrication of sodium carboxymethyl cellulose/reduced graphene oxide composite hydrogel and its application for Pb(II) removal. Micro & Nano Letters, 2020, 16(1): 30–38

Pinheiro J A, Marpues N D N, Villetti M A, Balaban R C. Polymer-decorated cellulose nanocrystals as environmentally friendly additives for olefin-based drilling fluids. International Journal of Molecular Sciences, 2020, 22(1): 352

Shipra J, Tamanna T, Bharti G. Rosin-modified o-cresol novolac based vinyl ester thermosets containing methacrylated lignin model compounds: synthesis, curing and thermo-mechanical analysis. Journal of Polymer Research, 2021, 28(4): 111

Zhu E Q, Xu G F, Sun S, Yang J, Yang H Y, Wang D W, Guo Z H, Shi Z J, Deng J. Rosin acid modification of bamboo powder and thermoplasticity of its products based on hydrothermal pretreatment. Advanced Composites and Hybrid Materials, 2021, 4(3): 584–590

Ossei-Bremang R N, Kemausuor F. A decision support system for the selection of sustainable biomass resources for bioenergy production. Environment Systems & Decisions, 2021, 41(3): 437–454

Yang L, Wang X, Dai M, Chen B, Qiao Y, Deng H, Zhang D, Zhang Y, Almeida C M V. Shifting from fossil-based economy to bio-based economy: status quo, challenges, and prospects. Energy, 2021, 228: 7411

Hao C, Liu T, Zhang S, Liu W, Shan Y, Zhang J. Triethanolamine-mediated covalent adaptable epoxy network: excellent mechanical properties, fast repairing, and easy recycling. Macromolecules, 2020, 53(8): 3110–3118

He C, Shi S, Wang D, Helms B A, Russell T P. Poly(oxime-ester) vitrimers with catalyst-free bond exchange. Journal of the American Chemical Society, 2019, 141(35): 13753–13757

Xu Y, Fu P, Dai S, Zhang H, Bi L, Jiang J, Chen Y. Catalyst-free self-healing fully bio-based vitrimers derived from tung oil: strong mechanical properties, shape memory, and recyclability. Industrial Crops and Products, 2021, 171: 113978

Xu Y, Dai S, Bi L, Jiang J, Zhang H, Chen Y. Catalyst-free self-healing bio-based vitrimer for a recyclable, reprocessable, and self-adhered carbon fiber reinforced composite. Chemical Engineering Journal, 2022, 429: 132518

Song J, Kim H, Jae W, Kim T, Futalan C M, Kim J. Porous ZnO/C microspheres prepared with maleopimaric acid as an anode material for lithium-ion batteries. Carbon, 2020, 165: 55–66

Yan X, Zhai Z, Xu J, Song Z, Shang S, Rao X. Hybrids of CO2-responsive water-redispersible single-walled carbon nanotubes by a surfactant based on natural rosin. ACS Omega, 2019, 4(21): 19478–19482

Xu X, Song Z, Shang S, Cui S, Rao X. Synthesis and properties of novel rosin-based water-borne polyurethane. Polymer International, 2011, 60(10): 1521–1526

Yang X, Guo L, Xu X, Shang S, Liu H. A fully bio-based epoxy vitrimer: self-healing, triple-shape memory and reprocessing triggered by dynamic covalent bond exchange. Materials & Design, 2020, 186: 108248

Altuna F I, Espósito L H, Ruseckaite R A, Stefani P M. Thermal and mechanical properties of anhydride-cured epoxy resins with different contents of biobased epoxidized soybean oil. Journal of Applied Polymer Science, 2011, 120(2): 789–798

Magdalena M, Monika S. The influence of curing systems on the cure characteristics and physical properties of styrene-butadiene elastomer. Materials, 2020, 13(23): 5329

Cheng S, Wojnarowska Z, Musial M, Kolodziej S, Drockenmuller E, Paluch M. Studies on ion dynamics of polymerized ionic liquids through the free volume theory. Polymer, 2021, 212: 123286

Tao Y, Fang L, Dai M, Wang C, Sun J, Fang Q. Sustainable alternative to bisphenol A epoxy resin: high-performance recyclable epoxy vitrimers derived from protocatechuic acid. Polymer Chemistry, 2020, 11(27): 4500–4506

Puspita I, Kurniati M, Winarti C, Maddu A. Cassava waste pulp—poly(acrylamide-acrylic acid) based hydrogels using gamma irradiation. Journal of Physics: Conference Series, 2021, 1912(1): 012017

Shi X, Ge Q, Lu H, Yu K. The nonequilibrium behaviors of covalent adaptable network polymers during the topology transition. Soft Matter, 2021, 17(8): 2104–2119

Reisinger D, Kaiser S, Rossegger E, Alabiso W, Rieger B, Schlogl S. Introduction of photolatent bases for locally controlling dynamic exchange reactions in thermo-activated vitrimers. Angewandte Chemie International Edition, 2021, 60(26): 14302–14306

Capelot M, Unterlass M M, Tournilhac F, Leibler L. Catalytic control of the vitrimer glass transition. ACS Macro Letters, 2012, 1(7): 789–792

Han R, Campbell K P. Dysferlin and muscle membrane repair. Current Opinion in Cell Biology, 2007, 19(4): 409–416

Tan P S, Somashekar A A, Casari P, Bhattacharyya D. Healing efficiency characterization of self-repairing polymer composites based on damage continuum mechanics. Composite Structures, 2019, 208: 367–376

Wang S, Urban M W. Self-healing polymers. Nature Reviews Materials, 2020, 5(8): 562–583

Wei K, Zhu G, Tang Y, Liu T, Xie J. The effects of crosslink density on thermo-mechanical properties of shape-memory hydroepoxy resin. Journal of Materials Research, 2013, 28(20): 2903–2910

Tian G, Zhu G, Xu S, Ren T. An investigation on sunlight-induced shape memory behaviors of PCL/TiN composites film. Smart Materials and Structures, 2019, 28(10): 105006

Teng J, Wang Z, Liu J, Sun X. Thermodynamic and shape memory properties of TPI/HDPE hybrid shape memory polymer. Polymer Testing, 2020, 81(C): 106257

Wang Z, Chang M, Kong F, Yun K. Optimization of thermo-mechanical properties of shape memory polymer composites based on a network model. Chemical Engineering Science, 2019, 207(C): 1017–1029

Wang Y, Zhou L, Wang Z, Huang H, Ye L. Analysis of internal stresses induced by strain recovery in a single SMA fiber-matrix composite. Composites Part B: Engineering, 2011, 42(5): 1135–1143

Shi Q, Yu K, Kuang X, Mu X, Dunn C K, Dunn M L, Wang T, Jerry Qi H. Recyclable 3D printing of vitrimer epoxy. Materials Horizons, 2017, 4(4): 598–607

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Grant No. 32171734) and the Scientific Research Funds of Huaqiao University (Grant No. 20BS201).

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Shen, Y., Tang, W., Li, J. et al. Rosin side chain type catalyst-free vitrimers with high cross-link density, mechanical strength, and thermal stability. Front. Chem. Sci. Eng. 17, 1267–1279 (2023). https://doi.org/10.1007/s11705-022-2291-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-022-2291-7