Abstract

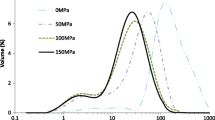

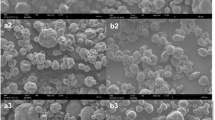

Non-thermal strategies have shown potential application in fruit processing. In this study, we evaluated the use of high hydrostatic pressure (HHP) (100–500 MPa) in the rheology of nectarine pulp and spray drying (190 °C/300.05 mL h−1) on powder properties. Empirical models were used to describe the rheological behavior of the pulp, in addition, the obtained powders were characterized in terms of their physical, morphological, structural and bioaccessibility properties. The treatment with HHP reduced the viscosity of the pulp, which showed pseudoplastic behavior and the Ostwald–de-Waele model showed the best fit (R2 > 0.99). While for the powder characteristics (yield between 34.58 and 59.19%), the GAB model best represents the water adsorption isotherms. The physical properties were influenced according to the applied pressure (p < 0.05) and zeta potential showed values in the range of − 28.78 mV to − 25.94 mV. It was seen that the pressure facilitated the extraction of total phenolic compounds, with a subsequent reduction in digestibility, the highlight being the pulp previously treated at 500 MPa, which presented a bioaccessibility of 31.61%. Morphologically, the increase in pressure changed the appearance of the surfaces from ovoid to spherical and rough, while for the FT-IR only the absorption intensities were modified. The HHP treatment applied to the pulp is a fast and efficient non-thermal method to improve the properties of the nectarine pulp and obtaining its powder by spray drying was feasible, guaranteeing greater stability during storage.

Graphical abstract

Similar content being viewed by others

Data availability

Research data are not shared.

References

I.B. Coutinho, M.B. Quezadas, L.F.G. de Souza, M. Nitz, K. Andreola, Spray drying of avocado pulp using the seed as an adjuvant. Powder Technol. 408, 117738 (2022). https://doi.org/10.1016/j.powtec.2022.117738

M. Cheng, J. He, C. Li, G. Wu, K. Zhu, X. Chen et al., Comparison of microwave, ultrasound and ultrasound-microwave assisted solvent extraction methods on phenolic profile and antioxidant activity of extracts from jackfruit (Artocarpus heterophyllus Lam.) pulp. LWT (2023). https://doi.org/10.1016/j.lwt.2022.114395

Y. Wang, Y. Hao, D. Zhou, L. Pan, K. Tu, Differences in commercial quality and carotenoids profile of yellow- and white-fleshed nectarine fruit during low temperature storage and the regulation of carotenoids by sugar. Postharvest Biol. Technol. 197, 112206 (2023). https://doi.org/10.1016/j.postharvbio.2022.112206

E.S. Silva, S.C.R. Brandão, A.L. da Silva, J.H.F. da Silva, A.C.D. Coêlho, P.M. Azoubel, Ultrasound-assisted vacuum drying of nectarine. J. Food Eng. 246, 119–124 (2019). https://doi.org/10.1016/j.jfoodeng.2018.11.013

S. Singh, S. Kawade, A. Dhar, S. Powar, Analysis of mango drying methods and effect of blanching process based on energy consumption, drying time using multi-criteria decision-making. Clean. Eng. Technol. 8, 100500 (2022). https://doi.org/10.1016/j.clet.2022.100500

B.A.O. Sanchez, S.M.C. Celestino, M.B. de Abreu Gloria, I.C. Celestino, M.I.O. Lozada, S.D.A. Júnior et al., Pasteurization of passion fruit Passiflora setacea pulp to optimize bioactivecompounds retention. Food Chem. 6, 100084 (2020)

O.Y. Barrón-García, M. Gaytán-Martínez, A.K. Ramírez-Jiménez, I. Luzardo-Ocampo, G. Velazquez, E. Morales-Sánchez, Physicochemical characterization and polyphenol oxidase inactivation of Ataulfo mango pulp pasteurized by conventional and ohmic heating processes. LWT 143, 111113 (2021). https://doi.org/10.1016/j.lwt.2021.111113

S.M. Castro, J.A. Saraiva, High-pressure processing of fruits and fruit products, in Emerging Technologies for Food Processing (2014), pp. 65–76. ISBN: 9780124114791

R.M. Ferreira, R.A. Amaral, A. Silva, S.M. Cardoso, J.A. Saraiva, Effect of high-pressure and thermal pasteurization on microbial and physico-chemical properties of Opuntia ficus-indica juices. Beverages 8(4), 84 (2022). https://doi.org/10.3390/beverages8040084

H.W. Huang, S.J. Wu, J.K. Lu, Y.T. Shyu, C.Y. Wang, Current status and future trends of high-pressure processing in food industry. Food Control 72, 1–8 (2017). https://doi.org/10.1016/j.foodcont.2016.07.019

R.B. Mastello, N.S. Janzantti, A. Bisconsin-Júnior, M. Monteiro, Impact of HHP processing on volatile profile and sensory acceptance of Pêra-Rio orange juice. Innov. Food Sci. Emerg. Technol. 45, 106–114 (2018). https://doi.org/10.1016/j.ifset.2017.10.008

R. Sun, R. Xing, J. Zhang, T. Deng, Y. Ge, W. Zhang, Y. Chen, Quality changes of HHP orange juice during storage: metabolomic data integration analyses. Food Chem. 404, 134612 (2023). https://doi.org/10.1016/j.foodchem.2022.134612

R.L.J. Almeida, N.C. Santos, W.B. de Brito Lima, C.E. de Araújo Padilha, N.S. Rios, E.S. Dos Santos, Effect of enzymatic hydrolysis on digestibility and morpho-structural properties of hydrothermally pre-treated red rice starch. Int. J. Biol. Macromol. 222, 65–76 (2022). https://doi.org/10.1016/j.ijbiomac.2022.09.089

Y. Ding, M. Wang, J. Wang, J. Diao, Y. Wu, J. Cheng, Q. Ban, Exploring the hydration promotion and cooking quality improvement of adlay seed by high hydrostatic pressure. LWT 171, 114158 (2022). https://doi.org/10.1016/j.lwt.2022.114158

N.C. Santos, R.L.J. Almeida, G.M. da Silva, J.V.F. Feitoza, V.M.D.A. Silva, M.M.T. Saraiva et al., Impact of high hydrostatic pressure (HHP) pre-treatment drying cashew (Anacardium occidentale L.): drying behavior and kinetic of ultrasound-assisted extraction of total phenolics compounds. J. Food Meas. Charact. (2022). https://doi.org/10.1007/s11694-022-01688-5

R. De la Peña-Armada, P. Rupérez, M.J. Villanueva-Suarez, I. Mateos-Aparicio, High hydrostatic pressure assisted by food-grade enzymes as a sustainable approach for the development of an antioxidant ingredient. LWT 169, 113968 (2022). https://doi.org/10.1016/j.lwt.2022.113968

M. Kaveh, A. Jahanbakhshi, Y. Abbaspour-Gilandeh, E. Taghinezhad, M.B.F. Moghimi, The effect of ultrasound pre-treatment on quality, drying, and thermodynamic attributes of almond kernel under convective dryer using ANNs and ANFIS network. J. Food Process Eng. 41(7), e12868 (2018). https://doi.org/10.1111/jfpe.12868

K. Lakshmipathy, N. Thirunavookarasu, N. Kalathil, D.V. Chidanand, A. Rawson, C.K. Sunil, Effect of different thermal and non-thermal pre-treatments on bioactive compounds of aqueous ginger extract obtained using vacuum-assisted conductive drying system. J. Food Process Eng. (2022). https://doi.org/10.1111/jfpe.14223

A. Özkan-Karabacak, B. Acoğlu, P. Yolci Ömeroğlu, Ö.U. Çopur, Microwave pre-treatment for vacuum drying of orange slices: drying characteristics, rehydration capacity and quality properties. J. Food Process Eng. 43(11), e13511 (2020). https://doi.org/10.1111/jfpe.13511

N.C. Santos, R.L.J. Almeida, G.M. da Silva, S.S. Monteiro, V.H. de Alcântara Ribeiro, A.P. de França Silva et al., Influence of high hydrostatic pressure (HHP) pretreatment on plum (Prunus salicina) drying: drying approach, physical, and morpho-structural properties of the powder and total phenolic compounds. J. Food Process. Preserv. 46(11), e16968 (2022). https://doi.org/10.1111/jfpp.16968

L. Yuan, F. Lao, X. Shi, D. Zhang, J. Wu, Effects of cold plasma, high hydrostatic pressure, ultrasound, and high-pressure carbon dioxide pretreatments on the quality characteristics of vacuum freeze-dried jujube slices. Ultrason. Sonochem. 90, 106219 (2022). https://doi.org/10.1016/j.ultsonch.2022.106219

M.R.I. Shishir, W. Chen, Trends of spray drying: a critical review on drying of fruit and vegetable juices. Trends Food Sci. Technol. 65, 49–67 (2017). https://doi.org/10.1016/j.tifs.2017.05.006

P. Nazni, G. Vaisnavi, Formulation and characterization of popsicles using dehydrated passion fruit juice with foxtail millet milk. J. Food Meas. Charact. (2022). https://doi.org/10.1007/s11694-022-01772-w

A. Baldelli, D.Y. Liang, Y. Guo, A. Pratap-Singh, Effect of the formulation on mucoadhesive spray-dried microparticles containing iron for food fortification. Food Hydrocoll. 134, 107906 (2023). https://doi.org/10.1016/j.foodhyd.2022.107906

Z. Tu, J. Irudayaraj, Y. Lee, Characterizing spray-dried powders through NIR spectroscopy: effect of two preparation strategies for calibration samples and comparison of two types of NIR spectrometers. Foods 12(3), 467 (2023). https://doi.org/10.3390/foods12030467

B.R. Bhandari, A. Senoussi, E.D. Dumoulin, A. Lebert, Spray drying of concentrated fruit juices. Dry. Technol. 11(5), 1081–1092 (1993). https://doi.org/10.1080/07373939308916884

V. Braga, L.R. Guidi, R.C. de Santana, M.F. Zotarelli, Production and characterization of pineapple-mint juice by spray drying. Powder Technol. 375, 409–419 (2020). https://doi.org/10.1016/j.powtec.2020.08.012

L. Wang, A. Clardy, D. Hui, Y. Wu, Physiochemical properties of encapsulated bitter melon juice using spray drying. Bioact. Carbohydr. Diet. Fibre 26, 100278 (2021). https://doi.org/10.1016/j.bcdf.2021.100278

M. Souza, A. Mesquita, P. Souza, G. Borges, T. Silva, A. Converti, M.I. Maciel, New functional non-dairy mixed tropical fruit juice microencapsulated by spray drying: physicochemical characterization, bioaccessibility, genetic identification and stability. LWT 152, 112271 (2021). https://doi.org/10.1016/j.lwt.2021.112271

A. Baldelli, H. Oguzlu, D.Y. Liang, A. Subiantoro, M.W. Woo, A. Pratap-Singh, Spray freeze drying of dairy products: effect of formulation on dispersibility. J. Food Eng. 335, 111191 (2022). https://doi.org/10.1016/j.jfoodeng.2022.111191

S. Srivastava, M. Bansal, D. Jain, Y. Srivastava, Encapsulation for efficient spray drying of fruit juices with bioactive retention. J. Food Meas. Charact. 16(5), 3792–3814 (2022). https://doi.org/10.1007/s11694-022-01481-4

M.A. Schutyser, E.M. Both, I. Siemons, E.M. Vaessen, L. Zhang, Gaining insight on spray drying behavior of foods via single droplet drying analyses. Dry. Technol. 37(5), 525–534 (2019). https://doi.org/10.1080/07373937.2018.1482908

S. Rojas-Moreno, F. Cárdenas-Bailón, G. Osorio-Revilla, T. Gallardo-Velázquez, J. Proal-Nájera, Effects of complex coacervation-spray drying and conventional spray drying on the quality of microencapsulated orange essential oil. J. Food Meas. Charact. 12, 650–660 (2018). https://doi.org/10.1007/s11694-017-9678-z

S.D.F. Sousa, A.J.D.M. Queiroz, R.M.F.D. Figueirêdo, F.B.D. Silva, Rheological behavior of whole and concentrated noni pulp. Braz. J. Food Technol. 20, e2016067 (2017). https://doi.org/10.1590/1981-6723.6716

O. Bashir, S.Z. Hussain, K. Ameer, T. Amin, I.A.M. Ahmed, M.O. Aljobair et al., Influence of anticaking agents and storage conditions on quality characteristics of spray dried apricot powder: shelf life prediction studies using Guggenheim-Anderson-de Boer (GAB) model. Foods 12(1), 171 (2023). https://doi.org/10.3390/foods12010171

A.A. Santana, D.M. Cano-Higuita, R.A. De Oliveira, V.R. Telis, Influence of different combinations of wall materials on the microencapsulation of jussara pulp (Euterpe edulis) by spray drying. Food Chem. 212, 1–9 (2016). https://doi.org/10.1016/j.foodchem.2016.05.148

Y. Suhag, G.A. Nayik, V. Nanda, Modelling of moisture sorption isotherms and glass transition temperature of spray-dried honey powder. J. Food Meas. Charact. 12(4), 2553–2560 (2018). https://doi.org/10.1007/s11694-018-9872-7

M. Smita, M. Bashir, S. Haripriya, Physicochemical and functional properties of peeled and unpeeled coconut haustorium flours. J. Food Meas. Charact. 13(1), 61–69 (2019). https://doi.org/10.1007/s11694-018-9919-9

J.I. Wells, Pharmaceutical Preformulation: The Physicochemical Properties of drug Substances (E. Horwood, Chichester, 1988)

R.V. Tonon, C. Brabet, M.D. Hubinger, Influence of process conditions on the physicochemical properties of açai (Euterpe oleraceae Mart.) powder produced by spray drying. J. Food Eng. 88(3), 411–418 (2008). https://doi.org/10.1016/j.jfoodeng.2008.02.029

J.L. Maia, T.N.P. Dantas, B.P.D.C. Neto, K.C. Borges, E.C. Lima, A.L.D.M.L. da Mata et al., Extract of spray-dried Malay apple (Syzygium malaccense L.) skin. J. Food Process Eng. 42(8), e13275 (2019). https://doi.org/10.1111/jfpe.13275

U. Gawlik-Dziki, D. Dziki, B. Baraniak, R. Lin, The effect of simulated digestion in vitro on bioactivity of wheat bread with Tartary buckwheat flavones addition. LWT 42(1), 137–143 (2009). https://doi.org/10.1016/j.lwt.2008.06.009

A. Brodkorb, L. Egger, M. Alminger, P. Alvito, R. Assunção, S. Ballance et al., INFOGEST static in vitro simulation of gastrointestinal food digestion. Nat. Protoc. 14(4), 991–1014 (2019). https://doi.org/10.1038/s41596-018-0119-1

S. Thummajitsakul, P. Piyaphan, S. Khamthong, M. Unkam, K. Silprasit, Comparison of FTIR fingerprint, phenolic content, antioxidant and anti-glucosidase activities among Phaseolus vulgaris L., Arachis hypogaea L. and Plukenetia volubilis L. Electron. J. Biotechnol. 61, 14–23 (2023). https://doi.org/10.1016/j.ejbt.2022.10.003

J. Liu, R. Wang, X. Wang, L. Yang, Y. Shan, Q. Zhang, S. Ding, Effects of high-pressure homogenization on the structural, physical, and rheological properties of lily pulp. Foods 8(10), 472 (2019). https://doi.org/10.3390/foods8100472

M. Opazo-Navarrete, G. Tabilo-Munizaga, A. Vega-Gálvez, M. Miranda, M. Pérez-Won, Effects of high hydrostatic pressure (HHP) on the rheological properties of Aloe vera suspensions (Aloe barbadensis Miller). Innov. Food Sci. Emerg. Technol. 16, 243–250 (2012). https://doi.org/10.1016/j.ifset.2012.06.006

M.D. Alvarez, R. Fuentes, W. Canet, Effects of pressure, temperature, treatment time, and storage on rheological, textural, and structural properties of heat-induced chickpea gels. Foods 4(2), 80–114 (2015). https://doi.org/10.3390/foods4020080

D.F. Keenan, N. Brunton, F. Butler, R. Wouters, R. Gormley, Evaluation of thermal and high hydrostatic pressure processed apple purees enriched with prebiotic inclusions. Innov. Food Sci. Emerg. Technol. 12(3), 261–268 (2011). https://doi.org/10.1016/j.ifset.2011.04.003

R.L. Almeida, N.C. Santos, T. dos Santos Pereira, V.M. de Alcântara Silva, V.H. de Alcantara Ribeiro, L.N. Silva et al., Estudo reológico da polpa de Jabuticaba com diferentes concentrações de goma arábica. Res. Soc. Dev. 9(3), e91932511 (2020). https://doi.org/10.33448/rsd-v9i3.2511

S.S. Sakr, S.H. Mohamed, A.A. Ali, W.E. Ahmed, R.M. Algheshairy, M.S. Almujaydil et al., Nutritional, physicochemical, microstructural, rheological, and organoleptical characteristics of ice cream incorporating adansonia digitata pulp flour. Foods 12(3), 533 (2023). https://doi.org/10.3390/foods12030533

B. Yuan, M.G.C. Danao, M. Lu, S.A. Weier, J.E. Stratton, C.L. Weller, High pressure processing (HPP) of aronia berry puree: pilot scale processing and a shelf-life study. Innov. Food Sci. Emerg. Technol. 47, 241–248 (2018). https://doi.org/10.1016/j.ifset.2018.03.006

S.L. Barros, N.C. Santos, R.D. Almeida, V.M. de Alcântara Silva, R.L.J. Almeida, A.P.S. Nascimento, Comportamento reológico e perfil de textura de iogurte integral com polpa de achachairu (Garcinia humilis). Revista Principia 1(47), 145–152 (2019). https://doi.org/10.18265/1517-03062015v1n47p145-152

C.G. Pereira, J.V. de Resende, T.M. Giarola, Relationship between the thermal conductivity and rheological behavior of acerola pulp: effect of concentration and temperature. LWT 58(2), 446–453 (2014). https://doi.org/10.1016/j.lwt.2014.04.016

B. Saberi, Q.V. Vuong, S. Chockchaisawasdee, J.B. Golding, C.J. Scarlett, C.E. Stathopoulos, Water sorption isotherm of pea starch edible films and prediction models. Foods 5(1), 1 (2015). https://doi.org/10.3390/foods5010001

G.A. Collazos-Escobar, N. Gutierrez-Guzman, H.A. Vaquiro-Herrera, J. Bon, J.V. Garcia-Perez, Thermodynamic analysis and modeling of water vapor adsorption isotherms of roasted specialty coffee (Coffee arabica L. cv. Colombia). LWT 160, 113335 (2022). https://doi.org/10.1016/j.lwt.2022.113335

J.A.C. Echavarria, A.M.R. Torres, J.E.Z. Montoya, Sorption isotherms and thermodynamic properties of the dry silage of red tilapia viscera (Oreochromis spp.) obtained in a direct solar dryer. Heliyon 7(4), e06798 (2021). https://doi.org/10.1016/j.heliyon.2021.e06798

L. Tavares, C.P.Z. Noreña, Characterization of the physicochemical, structural and thermodynamic properties of encapsulated garlic extract in multilayer wall materials. Powder Technol. 378, 388–399 (2021). https://doi.org/10.1016/j.powtec.2020.10.009

S.K. Velázquez-Gutiérrez, A.C. Figueira, M.E. Rodríguez-Huezo, A. Román-Guerrero, H. Carrillo-Navas, C. Pérez-Alonso, Sorption isotherms, thermodynamic properties and glass transition temperature of mucilage extracted from chia seeds (Salvia hispanica L.). Carbohydr. Polym. 121, 411–419 (2015). https://doi.org/10.1016/j.carbpol.2014.11.068

T. Qadri, H.R. Naik, S.Z. Hussain, B. Naseer, T. Bhat, F.J. Wani, Spray dried apple powder: qualitative, rheological, structural characterization and its sorption isotherm. LWT 165, 113694 (2022). https://doi.org/10.1016/j.lwt.2022.113694

D.P. Rosa, R.R. Evangelista, A.L.B. Machado, M.A.R. Sanches, J. Telis-Romero, Water sorption properties of papaya seeds (Carica papaya L.) formosa variety: an assessment under storage and drying conditions. LWT 138, 110458 (2021). https://doi.org/10.1016/j.lwt.2020.110458

J. Gawałek, Spray drying of chokeberry juice-antioxidant phytochemicals retention in the obtained powders versus energy consumption of the process. Foods 11(18), 2898 (2022). https://doi.org/10.3390/foods11182898

G.D. Tirta, L. Martin, M.D. Bani, K. Kho, I.T. Pramanda, L.P. Pui et al., Spray drying encapsulation of Pediococcus acidilactici at different inlet air temperatures and wall material ratios. Foods 12(1), 165 (2023). https://doi.org/10.3390/foods12010165

A.N. Yüksel, Development of yoghurt powder using microwave-assisted foam-mat drying. J. Food Sci. Technol. 58(7), 2834–2841 (2021). https://doi.org/10.1007/s13197-021-05035-2

K.H. Sarabandi, S.H. Peighambardoust, A.R. Sadeghi Mahoonak, S.P. Samaei, Effect of different carriers on microstructure and physical characteristics of spray dried apple juice concentrate. J. Food Sci. Technol. 55, 3098–3109 (2018). https://doi.org/10.1007/s13197-018-3235-6

C. Zhang, S.L.A. Khoo, P. Swedlund, Y. Ogawa, Y. Shan, S.Y. Quek, Fabrication of spray-dried microcapsules containing noni juice using blends of maltodextrin and gum acacia: physicochemical properties of powders and bioaccessibility of bioactives during in vitro digestion. Foods 9(9), 1316 (2020). https://doi.org/10.3390/foods9091316

S. Sarkhel, D. Manvi, C.T. Ramachandra, M. Manjunath, U.K. Nidoni, Studies on supercritical fluid extraction and spray drying effect on the quality of instant tea of Mulberry leaves (Morus alba L.). Meas. Food 7, 100052 (2022). https://doi.org/10.1016/j.meafoo.2022.100052

N. Jose, M.R. Ravindra, G.P. Deshmukh, Effect of dry-crystallization method on the engineering properties of an instant mix for rice flake-milk pudding. Meas. Food 7, 100044 (2022). https://doi.org/10.1016/j.meafoo.2022.100044

L.M. Cardona, M. Cortés-Rodríguez, F.J.C. Galeano, Optimization of fluidized bed agglomeration process of a pineapple powder mixture using a binder solution of ginger extract and vitamin C. LWT 171, 114075 (2022). https://doi.org/10.1016/j.lwt.2022.114075

M.A. Bednarska, E. Janiszewska-Turak, The influence of spray drying parameters and carrier material on the physico-chemical properties and quality of chokeberry juice powder. J. Food Sci. Technol. 57(2), 564–577 (2020). https://doi.org/10.1007/s13197-019-04088-8

D. Samyor, S.C. Deka, A.B. Das, Physicochemical and phytochemical properties of foam mat dried passion fruit (Passiflora edulis Sims) powder and comparison with fruit pulp. J. Food Sci. Technol. 58, 787–796 (2021). https://doi.org/10.1007/s13197-020-04596-y

M.A. Arebo, J.D. Feyisa, K.D. Tafa, N. Satheesh, Optimization of spray-drying parameter for production of better quality orange fleshed sweet potato (Ipomoea batatas L.) powder: selected physiochemical, morphological, and structural properties. Heliyon (2023). https://doi.org/10.1016/j.heliyon.2023.e13078

J.C.P. Pombo, H.H.B.R. de Medeiros, R.D.S. Pena, Optimization of the spray drying process for developing cupuassu powder. J. Food Sci. Technol. 57, 4501–4513 (2020). https://doi.org/10.1007/s13197-020-04487-2

A.H. Sourki, A. Koocheki, M. Elahi, Influence of β-glucan extracted from hull-less barley on droplet characterization, stability and rheological properties of soy protein isolate stabilized oil-in-water emulsions. J. Food Sci. Technol. 59(5), 1781–1791 (2022). https://doi.org/10.1007/s13197-021-05189-z

D.J. McClements, Food Emulsions: Principles, Practices, and Techniques (CRC Press, Boca Raton, 2015)

S. Siriamornpun, N. Weerapreeyakul, S. Barusrux, Bioactive compounds and health implications are better for green jujube fruit than for ripe fruit. J. Funct. Foods 12, 246–255 (2015). https://doi.org/10.1016/j.jff.2014.11.016

P. Kashyap, C.S. Riar, N. Jindal, Effect of extraction methods and simulated in vitro gastrointestinal digestion on phenolic compound profile, bio-accessibility, and antioxidant activity of Meghalayan cherry (Prunus nepalensis) pomace extracts. LWT 153, 112570 (2022). https://doi.org/10.1016/j.lwt.2021.112570

G.I. Peña-Vázquez, M.T. Dominguez-Fernández, B.D. Camacho-Zamora, M. Hernandez-Salazar, V. Urías-Orona, M.P. De Peña, A.L. de la Garza, In vitro simulated gastrointestinal digestion impacts bioaccessibility and bioactivity of Sweet orange (Citrus sinensis) phenolic compounds. J. Funct. Foods 88, 104891 (2022). https://doi.org/10.1016/j.jff.2021.104891

L. Pollini, A. Juan-García, F. Blasi, J. Mañes, L. Cossignani, C. Juan, Assessing bioaccessibility and bioavailability in vitro of phenolic compounds from freeze-dried apple pomace by LC-Q-TOF-MS. Food Biosci. (2022). https://doi.org/10.1016/j.fbio.2022.101799

W. Qin, S. Ketnawa, Y. Ogawa, Effect of digestive enzymes and pH on variation of bioavailability of green tea during simulated in vitro gastrointestinal digestion. Food Sci. Hum. Wellness 11(3), 669–675 (2022). https://doi.org/10.1016/j.fshw.2021.12.024

T. Lafarga, S. Villaró, A. Rivera, G. Bobo, I. Aguiló-Aguayo, Bioaccessibility of polyphenols and antioxidant capacity of fresh or minimally processed modern or traditional lettuce (Lactuca sativa L.) varieties. J. Food Sci. Technol. 57(2), 754–763 (2020). https://doi.org/10.1007/s13197-019-04108-7

A. Chandrasekara, F. Shahidi, Bioaccessibility and antioxidant potential of millet grain phenolics as affected by simulated in vitro digestion and microbial fermentation. J. Funct. Foods 4(1), 226–237 (2012). https://doi.org/10.1016/j.jff.2011.11.001

K. Cabezas-Terán, C. Grootaert, J. Ortiz, S. Donoso, J. Ruales, F. Van Bockstaele et al., In vitro bioaccessibility and uptake of β-carotene from encapsulated carotenoids from mango by-products in a coupled gastrointestinal digestion/Caco-2 cell model. Food Res. Int. 164, 112301 (2023). https://doi.org/10.1016/j.foodres.2022.112301

V. Valková, H. Ďúranová, A. Falcimaigne-Cordin, C. Rossi, F. Nadaud, A. Nesterenko et al., Impact of freeze- and spray-drying microencapsulation techniques on β-glucan powder biological activity: a comparative study. Foods 11(15), 2267 (2022). https://doi.org/10.3390/foods11152267

K.H. Lee, T.Y. Wu, L.F. Siow, Spray drying of red (Hylocereus polyrhizus) and white (Hylocereus undatus) dragon fruit juices: physicochemical and antioxidant properties of the powder. Int. J. Food Sci. Technol. 48(11), 2391–2399 (2013). https://doi.org/10.1111/ijfs.12230

K. Lim, M. Ma, K.D. Dolan, Effects of spray drying on antioxidant capacity and anthocyanidin content of blueberry by-products. J. Food Sci. 76(7), 156–164 (2011). https://doi.org/10.1111/j.1750-3841.2011.02286.x

R.L.J. Almeida, N.C. Santos, J.V.F. Feitoza, T. dos Santos Pereira, R. da Silva Eduardo, M.M. de Almeida Mota et al., Evaluation of the technological properties of rice starch modified by high hydrostatic pressure (HHP). Innov. Food Sci. Emerg. Technol. 83, 103241 (2022). https://doi.org/10.1016/j.ifset.2022.103241

F. Cincotta, M. Merlino, A. Verzera, E. Gugliandolo, C. Condurso, Innovative process for dried caper (Capparis spinosa L.) powder production. Foods 2022(11), 3765 (2022). https://doi.org/10.3390/foods11233765

A. Hamdi, I. Viera-Alcaide, R. Guillén-Bejarano, R. Rodríguez-Arcos, M.J. Muñoz, J.M. Monje Moreno, A. Jiménez-Araujo, Asparagus fructans as emerging prebiotics. Foods 12(1), 81 (2023). https://doi.org/10.3390/foods12010081

N. Nicolaou, Y. Xu, R. Goodacre, Fourier transform infrared spectroscopy and multivariate analysis for the detection and quantification of different milk species. J. Dairy Sci. 93(12), 5651–5660 (2010). https://doi.org/10.3168/jds.2010-3619

G.D. Feng, F. Zhang, L.H. Cheng, X.H. Xu, L. Zhang, H.L. Chen, Evaluation of FT-IR and Nile Red methods for microalgal lipid characterization and biomass composition determination. Bioresour. Technol. 128, 107–112 (2013). https://doi.org/10.1016/j.biortech.2012.09.123

M.A. Khatun, M. Razzak, M.A. Hossain, A. Hossain, M. Islam, M. Shahjalal et al., Gamma radiation processing of honey of mustard, black seed and lychee flower: measurement of antioxidant, antimicrobial, and Fourier transform infrared (FT-IR) spectra. Meas. Food 6, 100026 (2022). https://doi.org/10.1016/j.meafoo.2022.100026

Acknowledgements

The authors are grateful to supported by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) and Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq). The authors are grateful also to the Federal University of Rio Grande do Norte (UFRN), Federal University of Ceará (UFC), Federal University of Campina Grande (UFCG) for technical support.

Author information

Authors and Affiliations

Contributions

NCS: conceptualization, methodology, investigation, formal analysis, writing (draft and review), and visualization. RLJA: dara curation and writing (draft and review). GMS: formal analysis. JCA: formal analysis. RSS: data curation. LPSN: software. JVFF: methodology. LSSP: validation. ROC: methodology. NMAJ: formal analysis. YASB: conceptualization. VMAS: supervision, project administration and writing (draft and review). All authors read and approved the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Ethical approval

Ethics approval was not required for this research.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Santos, N.C., Almeida, R.L.J., da Silva, G.M. et al. Effects of high hydrostatic pressure (HHP) on the rheological properties of pulp nectarine and the spray drying on the powder properties. Food Measure 17, 5644–5659 (2023). https://doi.org/10.1007/s11694-023-02081-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-023-02081-6