Abstract

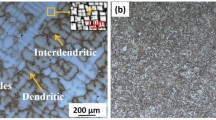

The effect of post-weld heat treatment (PWHT) temperatures (650, 750, 850, and 950°C with a 2-h hold time on the microstructure, intergranular corrosion resistance, and mechanical properties of Inconel 625/AISI 4130 steel bimetal plates, which was manufactured through pulsed tungsten inert gas, was investigated. The results showed that the as-welded Inconel 625 overlay is mainly composed of equiaxed dendrites and columnar dendrites. With an increase in PWHT temperatures, equiaxed dendrites transfer into columnar dendrites, and columnar dendrites transfer into cellular dendrites. It is observed that there are seldom residual equiaxed dendrites distributed in the heat-treated Inconel 625 overlay at 750°C, and the Inconel 625 overlay heat treated at 850 and 950°C consisted of columnar dendrites and cellular dendrites. The intergranular corrosion tests indicated that heat treatment at 650°C is beneficial to improve the intergranular corrosion resistance of the Inconel 625 overlay, but the corrosion rates increase sharply with the rise of PWHT temperatures. In addition, the tensile tests demonstrated that the PWHT has detrimental effect on the yield strength (YS) and tensile strength (TS) of the substrate; however, it is beneficial to the elongation. It is found that the heat-treated substrate at 650°C features relatively good YS, TS, and elongation compared with those of heat treated at higher temperatures. Therefore, considering the intergranular corrosion resistance and mechanical properties, 650°C is recommended as the optimal PWHT temperature for the Inconel 625/AISI 4130 steel bimetal plates.

Similar content being viewed by others

References

C.P. Alvarães, J.C.F. Jorge, L.F.G.D. Souza, L.S. Araújo, M.C. Mendes, H.N. Farneze, Microstructure and corrosion properties of single layer Inconel 625 weld cladding obtained by the electroslag welding process. J. Market. Res. 9, 16146–16158 (2020)

H.R. Zareie Rajani, S.A.A. Akbari Mousavi, S.F. Madani, Comparison of corrosion behavior between fusion cladded and explosive cladded Inconel 625/plain carbon steel bimetal plates. Mater. Des. 43, 467–474 (2013)

G. Longlong, Z. Hualin, L. Shaohu, L. Yueqin, X. Xiaodong, F. Chunyu, Formation quality optimization and corrosion performance of Inconel 625 weld overlay using hot wire pulsed TIG. Rare Metal Mat Eng. 45, 2219–2226 (2016)

L. Wang, H. Li, Q. Liu, L. Xu, S. Lin, K. Zheng, Effect of sodium chloride on the electrochemical corrosion of Inconel 625 at high temperature and pressure. J Alloy Compd. 703, 523–529 (2017)

L. Xu, J. Zhang, Y. Han, L. Zhao, H. Jing, Insights into the intergranular corrosion of overlay welded joints of X65-Inconel 625 clad pipe and its relationship to damage penetration. Corros Sci. (2019). https://doi.org/10.1016/j.corsci.2019.108169

S. Seddighi, F. Ostovan, E. Shafiei, M. Toozandehjani, A study on the effect of stress relief heat treatment on the microstructure and mechanical properties of dissimilar GTAW weld joints of Inconel 625 and A106 carbon steel. Mater Res Express. (2019). https://doi.org/10.1088/2053-1591/ab1fcb

V. Rajkumar, T.V. Arjunan, K.A. Rajesh, Investigations on hardfacing and wear characteristics of nickel-based Inconel 625 overlaid welds over AISI 347 pipe. J Braz Soc Mech Sci. (2020). https://doi.org/10.1007/s40430-019-2092-1

N. Wang, J. Shen, S. Hu, Y. Liang, Numerical analysis of the TIG arc preheating effect in CMT based cladding of Inconel 625. Eng. Res. Express. (2020). https://doi.org/10.1088/2631-8695/ab70e9

V. Rajkumar, T.V. Arjunan, A. Vasan, K.A. Rajesh, Effect of heat input on micro-hardness and shear strength of inconel 625 hardfacing onto AISI 347 steel pipes by GMAW process. J. phys. Conf. series. (2019). https://doi.org/10.1088/1742-6596/1355/1/012029

S. Ban, Y. Shin, S.R. Lee, H. Lee, Corrosion resistance of Inconel 625 overlay welded inside pipes as a function of heat treatment temperature. Int J Electrochem Sc. 11, 7764–7774 (2016)

A. Evangeline, P. Sathiya, Cold metal arc transfer (CMT) metal deposition of Inconel 625 superalloy on 316L austenitic stainless steel: microstructural evaluation, corrosion and wear resistance properties. Mater Res Express. (2019). https://doi.org/10.1088/2053-1591/ab0a10

A. Evangeline, P. Sathiya, Structure–property relationships of Inconel 625 cladding on AISI 316L substrate produced by hot wire (HW) TIG metal deposition technique. Mater Res Express. (2019). https://doi.org/10.1088/2053-1591/ab350f

L. Guo, F. Xiao, F. Wang, W. Wei, Y. He, F. Luo, Influence of heat treatments on microstructure, mechanical properties and corrosion resistance of Inconel 625 overlay cladded using PTIG. Mater Res Express. (2020). https://doi.org/10.1088/2053-1591/abb858

T.E. Abioye, D.G. McCartneyb, A.T. Clare, Laser cladding of Inconel 625 wire for corrosion protection. J Mater Process Tech. 217, 232–240 (2015)

M. Naghiyan Fesharaki, R. Shoja-Razavi, H.A. Mansouri, H. Jamali, Evaluation of the hot corrosion behavior of Inconel 625 coatings on the Inconel 738 substrate by laser and TIG cladding techniques. Optics Laser Technol. (2018). https://doi.org/10.1016/j.optlastec.2018.09.011

L.L. Guo, H.L. Zheng, S.H. Liu, Y.Q. Li, C.Y. Feng, X.D. Xu, Effect of heat treatment temperatures on microstructure and corrosion properties of Inconel 625 weld overlay deposited by PTIG. Int J Electrochem Sc. 11, 5507–5519 (2016)

M. Diehl, N. Messler, Using stress relaxation tests for evaluating and optimizing postweld heat treatments of alloy 625 welds. Weld J. 74, 109–114 (1995)

G. Marchese, M. Lorusso, S. Parizia, E. Bassini, J. Lee, F. Calignano, D. Manfredi, M. Terner, H. Hong, D. Ugues, M. Lombardi, S. Biamino, Influence of heat treatments on microstructure evolution and mechanical properties of Inconel 625 processed by laser powder bed fusion. Mater Sci Eng: A. 729, 64–75 (2018)

G. Marchese, E. Bassini, M. Calandri, E.P. Ambrosio, F. Calignano, M. Lorusso, D. Manfredi, M. Pavese, S. Biamino, P. Fino, Microstructural investigation of as-fabricated and heat-treated Inconel 625 and Inconel 718 fabricated by direct metal laser sintering: contribution of Politecnico di Torino and Istituto Italiano di Tecnologia (IIT) di Torino. Met. Powder Rep. 71, 273–278 (2016)

Y.L. Hu, X. Lin, S.Y. Zhang, Y.M. Jiang, X.F. Lu, H.O. Yang, W.D. Huang, Effect of solution heat treatment on the microstructure and mechanical properties of Inconel 625 superalloy fabricated by laser solid forming. J Alloy Compd. 767, 330–344 (2018)

X. Xing, X. Di, B. Wang, The effect of post-weld heat treatment temperature on the microstructure of Inconel 625 deposited metal. J Alloy Compd. 593, 110–116 (2014)

F. Xu, Y. Lv, Y. Liu, B. Xu, P. He, Effect of heat treatment on microstructure and mechanical properties of Inconel 625 alloy fabricated by pulsed plasma arc deposition. Phys. Procedia. 50, 48–54 (2013)

E.A. Lass, M.R. Stoudt, M.B. Katz, M.E. Williams, Precipitation and dissolution of δ and γ″ during heat treatment of a laser powder-bed fusion produced Ni-based superalloy. Scripta Mater. 154, 83–86 (2018)

L.Y. Xu, J.Y. Zhang, Y.D. Han, L. Zhao, H.Y. Jing, Insights into the intergranular corrosion of overlay welded joints of X65-Inconel 625 clad pipe and its relationship to damage penetration. Corr. Sci. (2019). https://doi.org/10.1016/j.corsci.2019.108169

Acknowledgments

This study is financially supported by the Natural Science Basic Research Plan in Shaanxi Province of China (No. 2020JQ-780), Open Foundation of Chongqing Engineering Technology Research Center for Light Alloy Materials and Processing (No. GCZX202001), and Graduate Student Innovation and Practice Ability Training Program Funding of Xi'an Shiyou University (No. YCS20211036).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, L., Xiao, F., Wang, F. et al. Effect of Post-Weld Heat Treatment Temperatures on Microstructure, Intergranular Corrosion Resistance, and Mechanical Properties of 4130 Steel with Inconel 625 Weld Overlay. J Fail. Anal. and Preven. 21, 1775–1783 (2021). https://doi.org/10.1007/s11668-021-01225-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-021-01225-4