Abstract

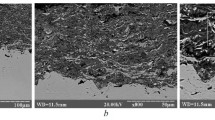

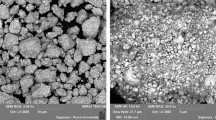

For the first time, the formation of coatings by detonation spraying (DS) of a binder-free tungsten carbide, WC, was studied. The coating phase composition was shown to depend on the O/C molar ratio in the oxygen-acetylene mixture used for the spraying. Along with WC, cubic carbide/oxycarbide WC1-xOy, tungsten semicarbide W2C and metallic W were present in the coatings formed at O/C = 0.9 and O/C = 1.0, indicating the formation of cermet composite coatings. When O/C was greater than 1.1, WC almost fully transformed into metallic tungsten in the coatings. The hardness of the cermet coatings was higher than that of the metallic tungsten-based coatings. During the coating formation, noticeable compression stresses accumulated in the deposited layers. These stresses do not lead to coating detachment or cracking: coatings with thicknesses of up to 500 μm retain their integrity.

Similar content being viewed by others

References

D. He, Y. Zhao, W. Li, L. Shang, L. Wang and G. Zhang, Superior Mechanical and Tribological Properties Governed by Optimized Modulation Ratio in WC/a-C Nano- Multilayers, Ceram. Int., 2021, 47(12), p 16861-16869. https://doi.org/10.1016/j.ceramint.2021.02.261

Y. Huan, K. Wu, C. Li, H. Liao, M. Debliquy and C. Zhang, Micro-Nano Structured Functional Coatings Deposited by Liquid Plasma Spraying, J. Adv. Ceram., 2020, 9(5), p 517-534. https://doi.org/10.1007/s40145-020-0402-9

Z. Sun, S. Zhu, W. Dong, H. Ding, Y. Bai, Y. Luo and P. Di, Densification During the Formation of WC-Based Coating Prepared by Electric Contact Strengthening, Ceram. Int., 2021, 47(12), p 16441-16449. https://doi.org/10.1016/j.ceramint.2021.01.122

Q. Wang, Q. Li, L. Zhang, D. Chen, H. Jin, J. Li, J. Zhang and C. Ban, Microstructure and Properties of Ni-WC Gradient Composite Coating Prepared by Laser Cladding, Ceram. Int., 2022, 48(6), p 7905-7917. https://doi.org/10.1016/j.ceramint.2021.11.338

L. Chen and G.-J. Yang, Epitaxial Growth and Cracking of Highly Tough 7YSZ Splats by Thermal Spray Technology, J. Adv. Ceram., 2018, 7(1), p 17-29. https://doi.org/10.1007/s40145-017-0252-2

M. Dai, X. Song, C. Lin, Z. Liu, W. Zheng and Y. Zeng, Investigation of Microstructure Changes in Al2O3 –YSZ Coatings and YSZ Coatings and Their Effect on Thermal Cycle Life, J. Adv. Ceram., 2022, 11(2), p 345-353. https://doi.org/10.1007/s40145-021-0538-2

D. Ni, Y. Cheng, J. Zhang, J.-X. Liu, J. Zou, B. Chen, H. Wu, H. Li, S. Dong, J. Han, X. Zhang, Q. Fu and G.-J. Zhang, Advances in Ultra-High Temperature Ceramics, Composites, and Coatings, J. Adv. Ceram., 2022, 11(1), p 1-56. https://doi.org/10.1007/s40145-021-0550-6

L. Qiao, Y. Wu, S. Hong, W. Long and J. Cheng, Wet Abrasive Wear Behavior of WC- Based Cermet Coatings Prepared by HVOF Spraying, Ceram. Int., 2021, 47(2), p 1829-1836. https://doi.org/10.1016/j.ceramint.2020.09.009

H. Wang, X. Yan, H. Zhang, M. Gee, C. Zhao, X. Liu and X. Song, Oxidation- Dominated Wear Behaviors of Carbide-Based Cermets: A Comparison Between WC- WB-Co and Cr 3 C 2 -NiCr Coatings, Ceram. Int., 2019, 45(17), p 21293-21307. https://doi.org/10.1016/j.ceramint.2019.07.113

J. Singh, S. Kumar and S. Mohapatra, Tribological Performance of Yttrium (III) and Zirconium (IV) Ceramics Reinforced WC–10Co4Cr Cermet Powder HVOF Thermally Sprayed on X2CrNiMo-17-12-2 Steel, Ceram. Int., 2019, 45(17), p 23126-23142. https://doi.org/10.1016/j.ceramint.2019.08.007

P. Fauchais, J. Heberlein and M. Boulos, Thermal Spray Fundamentals: From Powder to Part, Springer, New York, 2014.

L.-M. Berger, Application of Hardmetals as Thermal Spray Coatings, Int. J. Refract. Met. Hard Mater., 2015, 49, p 350-364. https://doi.org/10.1016/j.ijrmhm.2014.09.029

M. Karhu, J. Lagerbom, K. Kaunisto, T. Suhonen, J. Metsäjoki and E. Turunen, Nanocrystalline WC-Co HVAF Coatings by Utilizing Novel Powder Manufacturing Route Using Water-Soluble Raw Materials, J. Therm. Spray Technol., 2018, 27, p 196-206. https://doi.org/10.1007/s11666-017-0668-9

J. Sun, J. Zhao, Z. Huang, K. Yan, X. Shen, J. Xing, Y. Gao, Y. Jian, H. Yang and B. Li, A Review on Binderless Tungsten Carbide: Development and Application, Nanomicro Lett., 2020 https://doi.org/10.1007/s40820-019-0346-1

J. Poetschke, V. Richter and A. Michaelis, Fundamentals of Sintering Nanoscaled Binderless Hardmetals, Int. J. Refract. Met. Hard Mater., 2015, 49, p 124-132. https://doi.org/10.1016/j.ijrmhm.2014.04.022

B. Huang, L. Chen and S. Bai, Bulk Ultrafine Binderless WC Prepared by Spark Plasma Sintering, Scr. Mater., 2006, 54(3), p 441-445. https://doi.org/10.1016/j.scriptamat.2005.10.014

I.-J. Shon, B.-R. Kim, J.-M. Doh, J.-K. Yoon and K.-D. Woo, Properties and Rapid Consolidation of Ultra-Hard Tungsten Carbide, J. Alloys Compd., 2010, 489(1), p L4-L8. https://doi.org/10.1016/j.jallcom.2009.09.040

V. Ulianitsky, I. Batraev, A. Shtertser, D. Dudina, N. Bulina and I. Smurov, Detonation Spraying Behaviour of Refractory Metals: Case Studies for Mo and Ta- Based Powders, Adv. Powder Technol., 2018, 29(8), p 1859-1864. https://doi.org/10.1016/j.apt.2018.04.023

D. Rybin, I. Batraev, D. Dudina, A. Ukhina and V. Ulianitsky, Deposition of Tungsten Coatings by Detonation Spraying, Surf. Coat. Technol., 2021, 409, p 126943. https://doi.org/10.1016/j.surfcoat.2021.126943

V. Ulianitsky, A. Shtertser, S. Zlobin and I. Smurov, Computer-Controlled Detonation Spraying: From Process Fundamentals Toward Advanced Applications, J. Therm. Spray Technol., 2011, 20(4), p 791-801. https://doi.org/10.1007/s11666-011-9649-6

M. Guagliano, Relating Almen Intensity to Residual Stresses Induced by Shot Peening: A Numerical Approach, J. Mater. Process. Technol., 2001, 110(3), p 277-286. https://doi.org/10.1016/s0924-0136(00)00893-1

W. Tillmann, L. Hagen and W. Luo, Process Parameter Settings and Their Effect on Residual Stresses in WC/W2C Reinforced Iron-Based Arc Sprayed Coatings, Coatings, 2017, 7(8), p 125. https://doi.org/10.3390/coatings7080125

P. Babu, B. Basu and G. Sundararajan, Processing–Structure–Property Correlation and Decarburization Phenomenon in Detonation Sprayed WC–12Co Coatings, Acta Mater., 2008, 56(18), p 5012-5026. https://doi.org/10.1016/j.actamat.2008.06.023

E. Pruuel and A. Vasilev, Equation of State of Gas Detonation Products. Allowance for the Formation of the Condensed Phase of Carbon, Combust. Explos., 2021, 57(5), p 576-587. https://doi.org/10.1134/S0010508221050075

T. Gavrilenko, Y. Nikolaev, V. Ulianitsky, M. Kim, J. Hong. Computational Code for Detonation Spraying Process. Coddet C, ed. In: Thermal Spray: Meeting the Challenges of the 21st Century. Nice, France (May 25–29, 1998), ASM International, 1475-1483 (1998)

A.S. Kurlov and A.I. Gusev, Phase Equilibria in the W-C System and Tungsten Carbides, Russ. Chem. Rev., 2006, 75, p 617-636. https://doi.org/10.1070/RC2006v075n07ABEH003606

J.E. Krzanowski and J.L. Endrino, The Effects of Substrate Bias on Phase Stability and Properties of Sputter-Deposited Tungsten Carbide, Mater. Lett., 2004, 58, p 3437-3440. https://doi.org/10.1016/j.matlet.2004.04.036

D. Dudina, M. Korchagin, S. Zlobin, V. Ulianitsky, O. Lomovsky, N. Bulina, I. Bataev and V. Bataev, Compositional Variations in the Coatings Formed by Detonation Spraying of Ti3Al at Different O2/C2H2 Ratios, Intermetallics, 2012, 29, p 140-146. https://doi.org/10.1016/j.intermet.2012.05.010

V. Ulianitsky, D. Dudina, I. Batraev, A. Kovalenko, N. Bulina and B. Bokhonov, Detonation Spraying of Titanium and Formation of Coatings with Spraying Atmosphere-Dependent Phase Composition, Surf. Coat. Technol., 2015, 261, p 174-180. https://doi.org/10.1016/j.surfcoat.2014.11.038

Acknowledgments

This research was funded by the Ministry of Science and Higher Education of the Russian Federation (Project No. 075-15-2020-781). The authors are grateful to Prof. V. A. Sadykov for fruitful discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Batraev, I.S., Ulianitsky, V.Y., Shtertser, A.A. et al. Detonation Spraying of Binder-Free Tungsten Carbide: In-Situ Formation of Composite Coatings. J Therm Spray Tech 32, 249–258 (2023). https://doi.org/10.1007/s11666-022-01486-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01486-x