Abstract

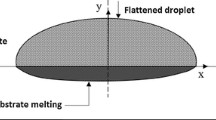

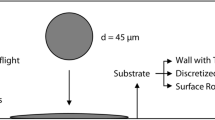

The coating deposit on the substrate in thermal spray coating process develops by solidification of individual molten particle which impacts, flattens and solidifies on the surface of the substrate. Droplet flattening and solidification typically involves rapid cooling. In this paper, a model for non-equilibrium rapid solidification of a molten droplet spreading onto a substrate is presented. Transient flow during droplet impact and its subsequent spreading is considered using the volume of fluid surface tracking method which was fully coupled with the rapid solidification model. The rapid solidification model includes undercooling, nucleation, interface tracking, non-equilibrium solidification kinetics and combined heat transfer and fluid flow as required to treat a non-stagnant splat formed from droplet flattening. The model is validated with the literature results on stagnant splats. Subsequently, using the model the characteristics of the rapidly solidifying interface for non-stagnant splat, such as interface velocity and interface temperature, are described and the effect of undercooling and interfacial heat transfer coefficient are highlighted. In contrast to the stagnant splat, the non-stagnant splat considered in this study displays interesting features in the rapidly solidifying interface. These are attributed to droplet thinning and droplet recoiling that occur during the droplet spreading process.

Similar content being viewed by others

Abbreviations

- c :

-

Specific heat (J kg−1 K−1)

- C :

-

Constant related to Darcy source term (kg m−3 s−1)

- D 0 :

-

Initial droplet diameter (m)

- f s :

-

Weight fraction of solid

- f l :

-

Weight fraction of liquid

- F :

-

Volume of fluid function

- F vol :

-

Continuum surface tension force (N m−3)

- \(\vec{g}\) :

-

Acceleration due to gravity vector (m s−2)

- \(\Delta G_{\text{am}}\) :

-

Activation energy for molecular migration (\({\text{J}}\,{\text{mol}}^{ - 1}\))

- h :

-

Heat transfer coefficient (\({\text{W}}\,{\text{m}}^{ - 2} \,{\text{K}}^{ - 1}\))

- H :

-

Enthalpy (J)

- \(\Delta H_{\text{m}}\) :

-

Heat of fusion (\({\text{J}}\;{\text{mol}}^{ - 1}\))

- k :

-

Thermal conductivity (W m−1 K−1)

- L d :

-

Latent heat of fusion (J kg−1)

- P :

-

Pressure (Pa)

- T :

-

Temperature (K)

- T i :

-

Interface temperature (K)

- t :

-

Time (s)

- \(t_{\text{s}}^{*}\) :

-

Dimensionless spreading time

- \(T_{\text{m}}\) :

-

Equilibrium melting temperature (K)

- \(T_{\text{N}}\) :

-

Nucleation temperature (K)

- \(T_{0}\) :

-

Initial temperature (K)

- \(\Delta T_{\text{i}}\) :

-

Interface undercooling (K)

- \(U_{0}\) :

-

Droplet’s initial impact velocity (m s−1)

- \(\vec{u}\) :

-

Continuum mixture velocity vector (m s−1)

- \(V_{\text{i}}\) :

-

Interface velocity (m s−1)

- μ :

-

Dynamic viscosity (kg m−1 s−1)

- \(\mu_{k}\) :

-

Linear kinetic coefficient (\({\text{m s K}}^{ - 1}\))

- \(\theta\) :

-

Contact angle

- \(\beta\) :

-

Kinetics constant

- \(\kappa\) :

-

Boltzmann’s constant (\({\text{J}}\;{\text{K}}^{ - 1}\))

- \(\delta\) :

-

Solid–liquid interface thickness (m)

- ξ:

-

Maximum spreading ratio

- air:

-

Air

- eff:

-

Effective

- i:

-

Solid–liquid interface

- l:

-

Liquid

- d:

-

Droplet

- l, d:

-

Liquid droplet

- 0:

-

Initial

- sub:

-

Substrate

- s, d:

-

Solid droplet

References

T. Chraska and A.H. King, Transmission Electron Microscopy Study of Rapid Solidification of Plasma Sprayed Zirconia—Part I. First Splat Solidification, Thin Solid Films, 2001, 397(1), p 30-39

T. Chraska and A.H. King, Transmission Electron Microscopy Study of Rapid Solidification of Plasma Sprayed Zirconia—Part II. Interfaces and Subsequent Splat Solidification, Thin Solid Films, 2001, 397(1), p 40-48

T.W. Clyne, Numerical Treatment of Rapid Solidification, Metall. Trans. B, 1984, 15(2), p 369-381

Y. Lahmar-Mebdoua, A. Vardelle, P. Fauchais, and D. Gobin, Modelling the Nucleation Process in Alumina Lamellae Deposited on a Steel Substrate, Int. J. Therm. Sci., 2010, 49(3), p 522-528

H. Liu, M. Bussmann, and J. Mostaghimi, A Comparison of Hyperbolic and Parabolic Models of Phase Change of a Pure Metal, Int. J. Heat Mass Transf., 2009, 52(5–6), p 1177-1184

M. Pasandideh-Fard, Y.M. Qiao, S. Chandra, and J. Mostaghimi, Capillary Effects During Droplet Impact on a Solid Surface, Phys. Fluids, 1996, 8(3), p 650-659

M. Bussmann, J. Mostaghimi, and S. Chandra, On a Three-Dimensional Volume Tracking Model of Droplet Impact, Phys. Fluids, 1999, 11(6), p 1406-1417

M. Pasandideh-Fard, V. Pershin, S. Chandra, and J. Mostaghimi, Splat Shapes in a Thermal Spray Coating Process: Simulations and Experiments, J. Therm. Spray Technol., 2002, 11(2), p 206-217

M. Xue, Y. Heichal, S. Chandra, and J. Mostaghimi, Modeling the Impact of a Molten Metal Droplet on a Solid Surface Using Variable Interfacial Thermal Contact Resistance, J. Mater. Sci., 2007, 42(1), p 9-18

S. Kamnis and S. Gu, Numerical Modelling of Droplet Impingement, J. Phys. D Appl. Phys., 2005, 38(19), p 3664-3673

Y.Z. Zheng, Q. Li, Z.H. Zheng, J.F. Zhu, and P.L. Cao, Modeling the Impact, Flattening and Solidification of a Molten Droplet on a Solid Substrate During Plasma Spraying, Appl. Surf. Sci., 2014, 317, p 526-533

C. Le Bot, S. Vincent, E. Meillot, F. Sarret, J.-P. Caltagirone, and L. Bianchi, Numerical Simulation of Several Impacting Ceramic Droplets with Liquid/solid Phase Change, Surf. Coati. Technol., 2015, 268, p 272-277

Y.M. Liao, Y.Z. Zheng, Z.H. Zheng, and Q. Li, Numerical Simulation of Zirconia Splat Formation and Cooling During Plasma Spray Deposition, Appl. Phys. A Mater. Sci. Process., 2016, 122(7), p 1-7

Y. Zhang, S. Matthews, A.T.T. Tran, and M. Hyland, Effects of Interfacial Heat Transfer, Surface Tension and Contact Angle on the Formation of Plasma-Sprayed Droplets Through Simulation Study, Surf. Coat. Technol., 2016, 307, p 807-816

P. Wei, Z. Wei, S. Li, C. Tan, and J. Du, Splat Formation During Plasma Spraying for 8 Mol % Yttria-Stabilized Zirconia Droplets Impacting on Stainless Steel Substrate, Appl. Surf. Sci., 2014, 321, p 538-547

R.C. Ruhl, Cooling Rates in Splat Cooling, Mater. Sci. Eng., 1967, 1, p 313-320

P.H. Shingu and R. Ozaki, Solidification Rate in Rapid Conduction Cooling, Metall. Trans. A, 1975, 6(1), p 33-37

T. Clyne, Numerical Treatment of Rapid Solidification, Metall. Trans. B, 1984, 15(June), p 369-381

G.-X. Wang and E.F. Matthys, Modelling of Heat Transfer and Solidification during Splat Cooling: Effect of Splat Thickness and Splat/Substrate Thermal Contact, Int. J. Rapid Solidif., 1991, 6, p 141-174

G.-X. Wang and E.F. Matthys, Numerical Modelling of Phase Change and Heat Transfer during Rapid Solidification Processes: Use of Control Volume Integrals with Element Subdivision, Int. J. Heat Mass Transf., 1992, 35(1), p 141-153

T. Bennett and D. Poulikakos, Heat Transfer Aspects of Splat-Quench Solidification: Modelling and Experiment, J. Mater. Sci., 1994, 29, p 2025-2039

Y.K. Chae, J. Mostaghimi, and T. Yoshida, Deformation and Solidification Process of a Super-Cooled Droplet Impacting on the Substrate under Plasma Spraying Conditions, Sci. Technol. Adv. Mater., 2000, 1(3), p 147-156

P.S. Wei and F.B. Yeh, Heat Transfer Coefficient in Rapid Solidification of a Liquid Layer on a Substrate, J. Heat Transfer, 2000, 122, p 792-800

H. Zhang, X.Y. Wang, L.L. Zheng, and S. Sampath, Numerical Simulation of Nucleation, Solidification, and Microstructure Formation in Thermal Spraying, Int. J. Heat Mass Transf., 2004, 47(10–11), p 2191-2203

H. Zhang, X.Y. Wang, L.L. Zheng, and X.Y. Jiang, Studies of Splat Morphology and Rapid Solidification During Thermal Spraying, Int. J. Heat Mass Transf., 2001, 44(24), p 4579-4592

G.-X. Wang, R. Goswami, S. Sampath, and V. Prasad, Understanding the Heat Transfer and Solidification of Plasma-Sprayed Yttria-Partially Stabilized Zirconia Coatings, Mater. Manuf. Process., 2004, 19(2), p 259-272

A. Kumar and S. Gu, Porous Surfaces via Impinging and Solidifying Molten Hollow Melt Droplets on Substrates, Trans. Indian Inst. Met., 2012, 65(6), p 771-775

A. Kumar and S. Gu, Modelling Impingement of Hollow Metal Droplets onto a Flat Surface, Int. J. Heat Fluid Flow, 2012, 37, p 189-195

A. Kumar, S. Gu, and S. Kamnis, Simulation of Impact of a Hollow Droplet on a Flat Surface, Appl. Phys. A Mater. Sci. Process., 2012, 109(1), p 101-109

A. Kumar, S. Gu, H. Tabbara, and S. Kamnis, Study of Impingement of Hollow ZrO2 Droplets onto a Substrate, Surf. Coat. Technol., 2013, 220, p 164-169

R.K. Shukla and A. Kumar, Substrate Melting and Re-solidification During Impact of High-Melting Point Droplet Material, J. Therm. Spray Technol., 2015, 24(8), p 1368-1376

N. Pathak, A. Kumar, A. Yadav, and P. Dutta, Effects of Mould Filling on Evolution of the Solid–Liquid Interface during Solidification, Appl. Therm. Eng., 2009, 29(17–18), p 3669-3678

W.D. Bennon, F.P. Incropera, and A. Continuum, Model for Momentum, Heat and Species Transport in Binary Solid–Liquid Phase Change Systems—I. Model Formulation, Int. J. Heat Mass Transf., 1987, 30(10), p 2161-2170

A.D. Brent, V.R. Voller, and K.J. Reid, Enthalpy-Porosity Technique for Modeling Convection-Diffusion Phase Change: Application to the Melting of a Pure Metal, Numer. Heat Transf., 1988, 13(3), p 297-318

J.U. Brackbill, D.B. Kothe, and C. Zemach, A Continuum Method for Modeling Surface Tension, J. Comput. Phys., 1992, 100(2), p 335-354

M. Pasandideh-Fard and J. Mostaghimi, On the Spreading and Solidification of Molten Particles in a Plasma Spray Process: Effect of Thermal Contact Resistance, Plasma Chem. Plasma Processing, 1996, 16(1), p 83-98

M. Vardelle, A. Vardelle, A.C. Leger, P. Fauchais, and D. Gobin, Influence of Particle Parameters at Impact on Splat Formation and Solidification in Plasma Spraying Processes, J. Therm. Spray Technol., 1995, 4(1), p 50-58

C.G. Levi and R. Mehrabian, Heat Flow During Rapid Solidification of Undercooled Metal Droplets, Metall. Trans. A, 1982, 13(2), p 221-234

J.W. Cahn, W.B. Hillig, and G.W. Sears, The Molecular Mechanism of Solidification, Acta Metall., 1964, 12(12), p 1421-1439

F.B. Yeh, P.S. Wei, and S.H. Chiu, Distinct Property Effects on Rapid Solidification of a Thin Liquid Layer on a Substrate Subject to Self-consistent Melting, J. Cryst. Growth, 2003, 247(3–4), p 563-575

J. Mostaghimi, S. Chandra, J. Mostaghimi, and S. Chandra, Air Bubble Entrapment under an Impacting Droplet Air Bubble Entrapment under an Impacting Droplet, Phys. Fluids, 2003, 2003(173), p 173-183

K. Shinoda, T. Koseki, and T. Yoshida, Influence of Impact Parameters of Zirconia Droplets on Splat Formation and Morphology in Plasma Spraying, J. Appl. Phys., 2006, 100(7), p 074903

K. Shinoda, Y. Kojima, and T. Yoshida, In Situ Measurement System for Deformation and Solidification Phenomena of Yttria-Stabilized Zirconia Droplets Impinging on Quartz Glass Substrate under Plasma-Spraying Conditions, J. Therm. Spray Technol., 2005, 14(4), p 511-517

S. Sampath, X. Jiang, J. Matejicek, A. Leger, and A. Vardelle, Substrate Temperature Effects on Splat Formation, Microstructure Development and Properties of Plasma Sprayed Coatings Part I: Case Study for Partially Stabilized Zirconia, Mater. Sci. Eng., A, 1999, 272(1), p 181-188

X. Jiang, J. Matejicek, and S. Sampath, Substrate Temperature Effects on the Splat Formation, Microstructure Development and Properties of Plasma Sprayed Coatings, Mater. Sci. Eng., A, 1999, 272(1), p 189-198

Y. Tanaka and M. Fukumoto, Investigation of Dominating Factors on Flattening Behavior of Plasma Sprayed Ceramic Particles, Surf. Coat. Technol., 1999, 120–121, p 124-130

L. Bianchi, A.C. Leger, M. Vardelle, A. Vardelle, and P. Fauchais, Splat Formation and Cooling of Plasma-Sprayed Zirconia, Thin Solid Films, 1997, 305(1–2), p 35-47

M. Fukumoto, K. Yang, K. Tanaka, T. Usami, T. Yasui, and M. Yamada, Effect of Substrate Temperature and Ambient Pressure on Heat Transfer at Interface between Molten Droplet and Substrate Surface, J. Therm. Spray Technol., 2011, 20(1–2), p 48-58

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shukla, R.K., Patel, V. & Kumar, A. Modeling of Rapid Solidification with Undercooling Effect During Droplet Flattening on a Substrate in Coating Formation. J Therm Spray Tech 27, 269–287 (2018). https://doi.org/10.1007/s11666-017-0666-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0666-y