Abstract

The mathematical model for the process of plasma-arc wire spraying is proposed, which describes behavior of molten metal droplets in the plasma jet, allowing for the processes of their deformation and gas-dynamic breakup. Numerical analysis of the processes of motion, heating, and breakup of molten metal droplets, detached from the sprayed wire at plasma-arc spraying of coatings, was performed. It is shown that during molten droplets movement in the plasma jet their multiple breakup takes place, leading to formation of sprayed particles with dimensions much smaller than dimensions of initial droplets, detached from the sprayed wire tip.

Similar content being viewed by others

References

L. Pawlowski, Science and Engineering of Thermal Spray Coatings, 2nd ed., Wiley, New York, 2008

R.I. Nigmatulin, Dynamics of Multiphase Media, Vol 1, Taylor & Francis, Philadelphia, 1990

Yu.S. Borisov, I.V. Krivtsun, A.F. Muzhichenko, E. Lugscheider, and U. Eritt, Computer Modelling of the Plasma Spraying Process, Paton Weld. J., 2000, 12, p 40-50

K. Remesh, S.C.M. Yu, H.W. Ng, and C.C. Berndt, Computational Study and Experimental Comparison of the In-flight Particle Behavior for an External Injection Plasma Spray Process, J. Therm. Spray Technol., 2003, 12(4), p 508-522

H.-P. Li and X. Chen, Three-dimensional Simulation of a Plasma Jet with Transverse Particle and Carrier Gas Injection, Thin Solid Films, 2001, 390, p 175-180

Yu.S. Borisov, A.S. Zatserkovny, and I.V. Krivtsun, Mathematical Modelling of the Process of Plasma Spraying of Composite Powders Allowing for the Exothermic Reaction of Synthesis of Coating Material, Paton Weld. J., 2004, 1, p 22-24

Yu. Borisov, A. Bushma, and I. Krivtsun, Modeling of Motion and Heating of Powder Particles in Laser, Plasma, and Hybrid Spraying, J. Therm. Spray Technol., 2006, 15(4), p 553-558

Yu.S. Korobov, V.N. Boronenkov, Pacчeт пapaмeтpoв движeния, нaгpeвa и oкиcлeния чacтиц пpи элeктpoдyгoвoй мeтaллизaции (Calculation of the parameters of movement, heating and oxidation of particles at electric-arc metalizing), Svarochnoje proizvodstvo, 1998, No 9, p 9-13. (in Russian)

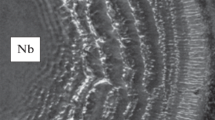

M.Yu. Kharlamov, I.V. Krivtsun, V.N. Korzhik, and S.V. Petrov, Formation of Liquid Metal Film at the Tip of Wire-anode in Plasma-arc Spraying, Paton Weld. J., 2011, 12, p 2-6

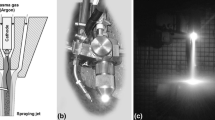

M.Yu. Kharlamov, I.V. Krivtsun, and V.N. Korzhyk, Dynamic Model of the Wire Dispersion Process in Plasma-Arc Spraying, J. Therm. Spray Technol., 2014, 23(3), p 420-430

E. Pfender and C.H. Chang, Plasma Spray Jets and Plasma-Particulate Interaction: Modeling and Experiments, Thermal Spray: Meeting the Challenges of the 21st Century, C. Coddet, Ed., May 25-29, 1998 (Nice, France), ASM International, Materials Park, 1998, p 315-327.

L.D. Landau, E.M. Lifshitz, Fluid Mechanics, 2nd ed. (Course of Theoretical Physics, Vol. 6), Butterworth-Heinemann, Boston, 1987

R. Schmehl, Advanced Modeling of Droplet Deformation and Breakup for CFD Analysis of Mixture Preparation, ILASS-Europe 2002, September 9-11, 2002 (Zürich, Schweiz), ILASS, 2002, p 1-10. http://www.ilasseurope.org/ICLASS/ilass2002/papers/012.pdf)

R. Clift, J.R. Grace, M.E. Weber, Bubbles, Droplets, and Particles, Dover Publications, New York, 2005

B.J. O’Donnel and B.T. Helenbrook, Drag on Ellipsoids at Finite Reynolds Number, Atomization Sprays, 2005, 15(4), p 363-376

E.E. Michaelides, Particles, Bubbles and Droplets: Their Motion, Heat And Mass Transfer, World Scientific Publ., New Jersey, 2006

A.A. Samarskii and B.D. Moiseyenko, An Economic Continuous Calculation Scheme for the Stefan Multidimensional Problem, USSR Comput Math. Math. Phys., 1965, 5(5), p 43-58

S.S. Kutateladze, Fundamentals of Heat Transfer, Academic Press, New York, 1963

S.V. Dresvin, A.V. Donskoj, V.M. Goldfarb, and V.S. Klubnikin, Физикa и тexникa низкoтeмпepaтypнoй плaзмы (Physics and Technology of Low-temperature Plasma), Atomizdat, 1972 (in Russian)

Ch.J. Knight, Theoretical Modeling of Rapid Surface Vaporization with Back Pressure, AIAA J., 1979, 17(5), p 519-523

A.M. Podvisotskii, V.V. Dubrovskii, Кpитичecкиe ycлoвия paзpyшeния кaпeль гaзoвым пoтoкoм (Critical Conditions of Droplet Breakup by Gas Flow), Phys. Aerodispersed Syst, 1998, 37, p 32-37, (in Russian). http://phys.onu.edu.ua/files/journals/fas/articles/37/fas37_podvisockiy.pdf

M. Pilch and C.A. Erdman, Use of Breakup Time Data and Velocity History Data to Predict the Maximum Size of Stable Fragments for Acceleration-induced Breakup of Liquid Droplet, Int. J. Multiphase Flow, 1987, 13, p 741-757

M.Yu. Kharlamov, I.V. Krivtsun, and V.N. Korzhyk, Numerical Simulation of Movement, Heating and Breakup of Particles, Formed at Wire Dispersion Under the Conditions of Plasma-arc Spraying, Mathematical Modeling and Information Technologies in Welding and Related Processes: Proceedings of 6th Intern. Conf., V.I. Makhnenko, Ed., May 29-June 1, 2012, (Katsiveli, Crimea, Ukraine), E.O. Paton Electric Welding Institute of the NAS of Ukraine, 2012, p 147-155

D.R. Guildenbecher, C. López-Rivera, and P.E. Sojka, Secondary Atomization, Exp. Fluids, 2009, 46(3), p 371-402

C. Lasheras, C. Eastwood, C. Martinez-Bazán, and J.L. Montañés, A Review of Statistical Models for the Break-up of an Immiscible Fluid Immersed into a Fully Developed Turbulent Flow, Int. J. Multiphase Flow, 2002, 28(2), p 247-278

J.M. Marchetti, L.E. Patruno, H.A. Jakobsen, and H.F. Svendsen, Mathematical Framework for Higher Order Breakage Scenarios, Chem. Eng. Sci., 2010, 65, p 5881-5886

R. Andersson and B. Andersson, On the Breakup of Fluid Particles in Turbulent Flows, AIChE J., 2006, 52(6), p 2020-2030

H. Bahmanyar and M.J. Slater, Studies of Droplet Break-up in Liquid-Liquid Systems in a Rotating Disc Contactor. Part I: Condition of no Mass Transfer, Chem. Eng. Technol., 1991, 14, p 79-89

P.J. Hill and K.M. Ng, Statistics of Multiple Particle Breakage, AIChE J., 1996, 42(6), p 1600-1611

M.Yu. Kharlamov, I.V. Krivtsun, V.N. Korzhik, S.V. Petrov, and A.I. Demianov, Mathematical Model of Arc Plasma Generated by Plasmatron with Anode Wire, Paton Weld. J., 2007, 12, p 9-14

J. Hu and H.L. Tsai, Heat and Mass Transfer in Gas Metal Arc Welding. Part I: The Arc, Int. J Heat Mass Transfer, 2007, 50(5–6), p 833-846

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kharlamov, M.Y., Krivtsun, I.V., Korzhyk, V.N. et al. Simulation of Motion, Heating, and Breakup of Molten Metal Droplets in the Plasma Jet at Plasma-Arc Spraying. J Therm Spray Tech 24, 659–670 (2015). https://doi.org/10.1007/s11666-015-0216-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0216-4