Abstract

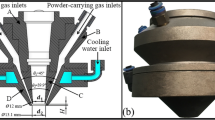

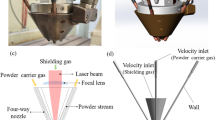

The results of theoretical and experimental investigations of direct metal deposition (DMD) processes involving a CO2-laser with the power up to 5 kW and wave length of 10.6 μm are presented. The physical and mathematical model of multi-layer gas flows with gas-jet transportation of metal powder particles has been developed. To simulate the flows of carrier and shaping gases in annular channels of a triple coaxial nozzle, Navier-Stokes equations were applied for an axisymmetric flow. Thermodynamics and powder particles transport are calculated from a discrete-trajectory model with due regard to particle collision with solid walls of the transport nozzle. It is shown that particles may overheat on their way between the nozzle and substrate; the overheating depends on the trajectories by which particles move, on their size, and time of their retention in the laser-radiation region. The results of performed experimental researches on DMD processes visualization are presented. Some results of numerical simulation and experimental data are compared and analyzed.

Similar content being viewed by others

Abbreviations

- t :

-

time

- {x, y} or {x α, α = 1, 2}:

-

cylindrical system of coordinates

- p, ρ, T, μ, λ:

-

gas pressure, density, temperature, viscosity, and thermal conductivity

- \( \vec{V} \), V:

-

velocity vector and absolute value of the velocity vector of the gas

- uα or u, v:

-

gas velocity in the x α or x, y directions, respectively

- \( \vec{n},\,\vec{\uptau } \) :

-

normal and tangential vectors

- \( \uptau_{ij} = \upmu \left( {{\frac{{\partial u_{i} }}{{\partial x_{j} }}} + {\frac{{\partial u_{j} }}{{\partial x_{i} }}} - \frac{2}{3}\updelta_{ij} {\frac{{\partial u_{k} }}{{\partial x_{k} }}}} \right) \) :

-

viscosity stress tensor; \( \updelta_{ij} = \left\{ \begin{gathered} \begin{array}{*{20}c} {0,} & {i \ne j} \\ \end{array} \hfill \\ \begin{array}{*{20}c} {1,} & {i = j} \\ \end{array} \hfill \\ \end{gathered} \right.; \)

- Re, Pr, Nu :

-

Reynolds, Prandtl, and Nusselt numbers

- c p , c v ,:

-

heat capacity at constant pressure and constant volume, respectively

- γ = c p /c v :

-

the ratio of specific heats

- R :

-

gas constant

- E, e:

-

gas total energy and internal energy, respectively

- \( \Upphi = \uptau_{ij} {\frac{{\partial u_{i} }}{{\partial x_{j} }}} \) :

-

dissipative function

- \( q = - \uplambda \nabla T \) :

-

a heat flux

- g :

-

acceleration of gravity

- σ:

-

Boltzmann constant

- A ab :

-

coefficient of laser radiation absorption

- I(x, y):

-

laser radiation intensity

- C d :

-

drag coefficient

- Gn, Gs, Gc:

-

flow rate of nozzle, shaping, and carrier gas

- r :

-

radius

- φ:

-

nonsphericity degree of a particle

- 0:

-

initial value

- p:

-

particle

- s:

-

solid

- m:

-

liquid or melting

- g:

-

gas

- n, τ:

-

normal and tangential components

References

D. Lepski and F. Bruckner, Laser Cladding, The Theory of Laser Materials Processing (Heat and Mass Transfer in Modern Technology). Springer Series in Material Science 119, J.M. Dowden, Ed., Springer, Canopus Academic Publishing, 2009

S. Angel, E. Ratte, W. Bleck, K. Bobzin, E. Lugscheider, R. Nickel, K. Richardt, N. Bagcivan, K. Walther, E.W. Kreutz, I. Kelbassa, and R. Poprawe, Open Porous Metallic Foams with Thermal Barrier Coating and Cooling Hole Array for High Temperature Turbine Applications, High Temp. Mater. Process., 2007, 11(3), p 321-343

S. Nowotny, S. Scharek, E. Beyer, and K.-H. Richter, Laser Beam Build-Up Welding: Precision in Repair, Surface Cladding, and Direct 3D Metal Deposition, J. Therm. Spray Tech., 2007, 16(3), p 334-348

I. Smurov, Laser Cladding and Laser Assisted Direct Manufacturing, Surf. Coat. Technol., 2008, 202, p 4496-4502

C.-Y. Liu and J. Lin, Thermal Processes of a Powder Particle in Coaxial Laser Cladding, Optics Laser Technol., 2003, 35, p 81-86

L. Han, F.W. Liou, and K.M. Phatak, Modeling of Laser Cladding with Powder Injection, Metall. Mater. Trans. B, 2004, 35B, p 1139-1150

J. Choi, L. Han, and Y. Hua, Modeling and Experiments of Laser Cladding with Droplet Injection, Trans. ASME, 2005, 127, p 978-986

H. Pan and F. Liou, Numerical Simulation of Metallic Powder Flow in a Coaxial Nozzle for the Laser Aided Deposition Process, J. Mater. Process. Technol., 2005, 168, p 230-244

H. Qia, J. Mazumder, and H. Ki, Numerical Simulation of Heat Transfer and Fluid Flow in Coaxial Laser Cladding Process for Direct Metal Deposition, J. Appl. Phys., 2006, 100, p 024903. doi:10.1063/1.2209807

S. Zekovic, R. Dwivedi, and R. Kovacevic, Numerical Simulation and Experimental Investigation of Gas-powder Flow from Radially Symmetrical Nozzles in Laser-Based Direct Metal Deposition, Int. J. Mach. Tools Manuf., 2007, 47, p 112-123

P. Peyre, P. Aubry, R. Fabbro, R. Neveu, and A. Longuet, Analytical and Numerical Modeling of the Direct Metal Deposition Laser Process, J. Phys. D: Appl. Phys., 2008, 41, p 025403 (10 pp)

N.N. Yanenko et al., Economical Methods for Solving the Problems of Gas Dynamics, Lect. Notes Phys., 1981, 141, p 448-453

X.-D. Liu, S. Osher, and T. Chan, Weighted Essentially Non-Oscillatory Schemes, J. Comput. Phys., 1994, 115, p 200-212

P. Taheri and C. Dehghanian, A Phenomenological Model of Nanocrystalline Coating Production Using the Plasma Electrolytic Saturation (PES) Technique, Trans. B: Mech. Eng., 2009, 16(1), p 87-91

M.V. Kravtsov, Resistance to the Free Steady-State Motion of a Sphere in a Viscous Medium, J. Eng. Phys., 1968, 15(3), p 464-470

H.-P. Li, X. Chen, Plasma. Three-Dimensional Modeling of the Turbulent Plasma Jet Impinging upon a Flat Plate and with Transverse Particle and Carrier-Gas Injection, Chem. Plasma Process., 2002, 22(1), p 27-58

A. Haider and O. Levenspiel, Drag Coefficient and Terminal Velocity of Spherical and Nonspherical Particles, Powder Technol., 1989, 58(1), p 63-70

M. Sommerfeld and N. Huber, Experimental Analysis and Modeling of Particle-Wall Collisions, Int. J. Multiph. Flow, 1999, 25(6/7), p 1457-1489

B.V.R. Vittal and W. Tabakoff, Two-Phase Flow Around a Two-Dimensional Cylinder, AIAA J., 1987, 25(5), p 648-654

M. Doubenskaya, Ph. Bertrand, and I. Smurov, Optical Monitoring of Nd:YAG Laser Cladding, Thin Solid Films, 2003, 453-454C, p 447-485

Acknowledgment

This research was supported by the Russian Foundation for Basic Research (Grant No. 08-08-00238_a).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kovalev, O.B., Zaitsev, A.V., Novichenko, D. et al. Theoretical and Experimental Investigation of Gas Flows, Powder Transport and Heating in Coaxial Laser Direct Metal Deposition (DMD) Process. J Therm Spray Tech 20, 465–478 (2011). https://doi.org/10.1007/s11666-010-9539-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-010-9539-3