Abstract

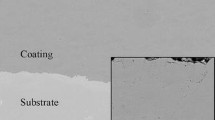

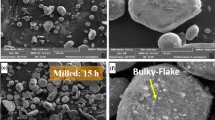

Free-standing VPS and HVOF CoNiCrAlY coatings were produced. The as-sprayed HVOF coating retained the γ/β microstructure of the feedstock powder, and the VPS coating consisted of a single (γ) phase. A 3-h, 1100 °C heat treatment in vacuum converted the single-phase VPS coating to a two-phase γ/β microstructure and coarsened the γ/β microstructure of the HVOF coating. Oxidation of free-standing as-sprayed and heat-treated coatings of each type was carried out in air at 1100 °C for a duration of 100 h. Parabolic rate constant(s), K p, were determined for free-standing, as-sprayed VPS and HVOF coatings as well as for free-standing coatings that were heat treated prior to oxidation. The observed increase in K p following heat treatment is attributed to a sintering effect eliminating porosity from the coating during heat treatment. The lower K p values determined for both HVOF coatings compared to the VPS coatings is attributed to the presence of oxides in the HVOF coatings, which act as the barrier to diffusion. Oxidation of the as-sprayed coatings produced a dual-layer oxide consisting of an inner α-Al2O3 layer and outer spinel layer. Oxidation of the heat-treated samples resulted in a single-layer oxide, α-Al2O3. The formation of a thin α-Al2O3 layer during heat treatment appeared to prevent nucleation and growth of spinel oxides during subsequent oxidation.

Similar content being viewed by others

References

J. Toscano, R.Vaβen, A. Gil, M. Subanovic, D. Naumenko, L. Singheiser, W.J. Quadakkers, Parameters affecting TGO growth and adherence on MCrAlY-bond coats for TBC’s, Surface and Coatings Technology, 2006, 201, p 3906-3910, in English.

W. Brandl, G. Marginean, D. Maghet, D. Utu (2004) Effects of Specimen Treatment and Surface Preparation on the Isothermal Oxidation Behavior of the HVOF-sprayed MCrAlY Coatings. Surface and Coatings Technology 188-189:20-26

W. Brandl, H.J. Grabke, D. Toma, J. Krüger (1996) The Oxidation Behaviour of Sprayed MCrAlY Coatings. Surface and Coatings Technology 86-87:41-47

M.P. Taylor.:An oxidation study of an MCrAlY overlay coating, Materials at High Temperatures, 2005, 22, p 433-436, in English

D. Zhang, S.J. Harris, and D.G. McCartney, Mechanical Properties and Microstructure of HVOF Sprayed Co and Ni Alloy Coatings, Thermal Spray 2003, Proceedings of the International Thermal Spray Conference, (Orlando, FL, USA), ASM International, 2003, p 829-836 (in English)

R. Prescott, M.J. Graham, The formation of aluminium oxide scales on high-temperature alloys, Oxidataion of Metals, 1992, 38, p 233-254, in English

F. Tang, L. Ajdelsztajn, and J.M. Schoenung, Effects of Cryomilling on the Oxidation of Thermally Sprayed MCrAlY, Thermal Spray 2004, Proceedings of the International Thermal Spray Conference, (Osa Japan), 2004, p 148-153 (in English)

F. Tang, L. Ajdelsztajn, G.E. Kim, V. Provenzano, J.M. Schoenung, Effects of surface oxidation during HVOF processing on the primary stage oxidation of a CoNiCrAlY coating, Surface and Coatings Technology, 2004,185, p 228-233, in English

H. Choi, B. Yoon, H. Kim, C. Lee, Isothermal oxidation of air plasma spray NiCrAlY bond coatings, Surface and Coatings Technology, 2002,150, p 297-308, in English

P. Poza, P.S. Grant, Microstructure evolution of vacuum plasma sprayed CoNiCrAlY coatings after heat treatment and isothermal oxidation, Surface and Coatings Technology, 2006, 201, p 2887-2896, in English

K. Fritscher, Y.T. Lee (2005). Investigation of an As-Sprayed NiCoCrAlY overlay Coating—Microstructure and Evolution of the Coating. Materials and Corrosion 56(1):5-14

L. Ajdelsztajn, J.A. Picas, G.E. Kim, F.L. Bastian, J. Schoenung, V. Provenzano, Oxidation behavior of HVOF sprayed nanocrystalline NiCrAlY powder, Materials Science and Engineering A, 2002, 338, p 33-43, in English

V. Higuera, F.J. Belzunce, J. Riba, Influence of the thermal-spray procedure on the properties of a CoNiCrAlY coating, Surface and Coatings Technology, 2006, 200, p 5550-5556, in English

R. Mobarra, A.H. Jafari, and M. Karaminezhaad, Hot corrosion behavior of MCrAlY coatings on IN738LC, Surface and Coatings Technology, 201 (6), pp. 2202-2207, 2006

M. Shibata, S. Kuroda, M. Watanabe, Y. Sakamoto (2006) Oxidation Property of CoNiCrAlY Coatings Prepared by Various Thermal Spraying Techniques. Materials Science Forum 522-523:339-344

A. Feuerstein, J. Knapp, T. Taylor, A. Ashary, A. Bolcavage, and N. Hitchman, Technical and economical aspects of current thermal barrier coating systems for gas turbine engines by thermal spray and EBPVD: A review, Journal of Thermal Spray Technology, 17 (2), pp. 199-213, 2008

Y. Itoh, M. Saitoh, M. Tamura, Characteristics of MCrAlY coatings sprayed by high velocity oxy-fuel spraying system, Journal of Engineering for Gas Turbines and Power, 2000, 122, p 43-49

W. Brandl, D. Toma, J. Krüger, H.J. Grabke, G. Matthäus (1997). The Oxidation Behaviour of HVOF Thermal-sprayed MCrAlY Coatings. Surface and Coatings Technology 94-95:21-26

C.H. Lee, H.K. Kim, H.S. Choi, H.S. Ahn, Phase transformation and bond coat oxidation behavior of plasma-sprayed zirconia thermal barrier coating, Surface and Coatings Technology, 2000, 124, p 1-12, in English

F. Tang, L. Ajdelsztajn, J.M. Schoenung, Characterisation of oxide scales formed on HVOF NiCrAlY coatings with various oxygen contents introduced during thermal spraying, Scripta Materialia, 2004, 51, p 25-29, in English

Acknowledgments

We acknowledge with thanks the facilities that were provided to make the VPS coatings at The University of Cambridge, courtesy of Prof. T.W. Clyne and with the assistance of Mr K.A. Roberts.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saeidi, S., Voisey, K.T. & McCartney, D.G. The Effect of Heat Treatment on the Oxidation Behavior of HVOF and VPS CoNiCrAlY Coatings. J Therm Spray Tech 18, 209–216 (2009). https://doi.org/10.1007/s11666-009-9311-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-009-9311-8