Abstract

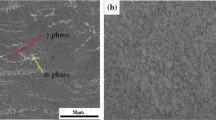

During the forming-reaction integrated process of NiAl alloy thin-walled components, Ni/Al laminates exhibit a complicated deformation behavior. In the present study, a physical-based constitutive model for the preparation of an Ni/Al laminate by vacuum hot-pressing was developed, with consideration of the load-bearing effect and microcracks in the diffusion layers, interface strengthening, and back stress strengthening. The load-bearing effect of the diffusion layer and interface strengthening increased the overall flow stress of the Ni/Al laminate, but did not affect the strain hardening rate. Multiple microcracks in the diffusion layer result into a gradual increase in the strain-softening effect. Unlike in other metal laminates, back stress only exists in the Al layers of an Ni/Al laminate. A gradually increasing back stress can significantly increase the flow stress and strain hardening rate at a strain of less than 0.085, and a gradually decreasing back stress leads to a reduction in the strain hardening rate. Ni/Al laminates with diffusion layers of various thicknesses was used to further verify the robustness of the constitutive model.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

X. Cai, Z. Li, X. Jiao, J. Wang, X. Kang, P. Feng, F. Akhtar, and X. Wang, Preparation of Porous NiAl Intermetallic with Controllable Shape and Pore Structure by Rapid Thermal Explosion with Space Holder, Met. Mater. Int., 2021, 27(10), p 4216–4224.

Y.M. Li, X.G. Wang, Z.H. Tan, Y.H. Yang, J.L. Liu, J.D. Liu, J.G. Li, Y.Z. Zhou, and X.F. Sun, Solidification and Evolution of beta-NiAl Phase in a Re-Containing Single Crystal Superalloy, Met. Mater. Int., 2022, 28(10), p 2305–2317.

Y. Du, G. Fan, Q. Wang, and L. Geng, Synthesis Mechanism and Strengthening Effects of Laminated NiAl by Reaction Annealing, Metall. Mater. Trans. A, 2017, 48(1), p 168–177.

G.H. Fan, Q.W. Wang, Y. Du, L. Geng, W. Hu, X. Zhang, and Y.D. Huang, Producing Laminated NiAl with Bimodal Distribution of Grain Size by Solid-Liquid Reaction Treatment, Mater. Sci. Eng. A, 2014, 590, p 318–322.

Y. Sun, P. Lin, and S. Yuan, Deformation and Fracture Behavior of the Novel NiAl Alloy Sheet with Bimodal Laminated Structure by In-Situ Reaction Synthesis, Intermetallics, 2020, 127, p 106944.

Y. Sun, P. Lin, and S.J. Yuan, A Novel Method for Fabricating NiAl Alloy Sheet Components Using Laminated Ni/Al Foils, Mater. Sci. Eng. A, 2019, 754, p 428–436.

Y. Sun, P. Lin, and S.J. Yuan, A Novel Process for Integrated Forming and Reaction Synthesis of NiAl Alloy Curved shells, J. Mater. Process. Technol., 2020, 285, p 116798.

B. Wang, D. Wang, J. Zhao, H. Ning, and G. Liu, Deformation Behavior and Fracture Mechanism of a Novel Laminated Ni/Al Sheets During In-Situ Tensile Process, Mater. Sci. Eng. A, 2021, 827, p 142050.

H. Wang, R. Kou, H. Yi, S. Figueroa, and K.S. Vecchio, Mesoscale Hetero-Deformation Induced (HDI) Stress in FeAl-Based Metallic-Intermetallic Laminate (MIL) Composites, Acta Mater., 2021, 213, 116949.

Z. Yu, T. Wang, C. Liu, Y. Ma, and W. Liu, Investigation on Microstructure, Mechanical Properties and Fracture Mechanism of Mg/Al Laminated Composites, Mater. Sci. Eng. A, 2022, 848, p 143410.

T.Q. Mo, Z.J. Chen, H. Chen, C. Hu, W.J. He, and Q. Liu, Multiscale Interfacial Structure Strengthening Effect in Al Alloy Laminated Metal Composites Fabricated by Accumulative Roll Bonding, Mater. Sci. Eng. A, 2019, 766, p 138354.

M. Huang, C. Xu, G. Fan, E. Maawad, W. Gan, L. Geng, F. Lin, G. Tang, H. Wu, and Y. Du, Role of Layered Structure in Ductility Improvement of Layered Ti-Al Metal Composite, Acta Mater., 2018, 153, p 235–249.

T. Huang, M. Zhan, Y. Pei, N. Xiang, F. Yang, Y. Li, J. Guo, X. Chen, and F. Chen, Establishment of Constitutive Relationships for Laminated Composites Considering the Variation of the Microhardness with the Strain in the Heterostructure Layers and Bonding Regions, JOM, 2019, 71(11), p 3962–3970.

H. Mecking and U.F. Kocks, Kinetics of Flow and Strain-Hardening, Acta Metall., 1981, 29(11), p 1865–1875.

W. Chen, W. He, Z. Chen, B. Jiang, and Q. Liu, Extraordinary Room Temperature Tensile Ductility of Laminated Ti/Al Composite: Roles of Anisotropy and Strain Rate Sensitivity, Int. J. Plast., 2020, 133, p 102806.

B. He, W. Xu, and M. Huang, Effect of Boron on Bainitic Transformation Kinetics After Ausforming in Low Carbon Steels, J. Mater. Sci. Technol., 2017, 33(12), p 1494–1503.

Y.F. Wang, M.S. Wang, X.T. Fang, F.J. Guo, and Y.T. Zhu, Extra Strengthening in a Coarse/Ultrafine Grained Laminate: Role of Gradient Interfaces, Int. J. Plast., 2019, 123, p 196–207.

R. Yuan and H. Du, Modeling the Effects of Interface Spacing on the Mechanical Properties of Heterogeneous Laminates, Comput. Mater. Sci., 2019, 173, 109391.

X. Chen, B. Zhang, Q. Zou, G. Huang, S. Liu, J. Zhang, A. Tang, B. Jiang, and F. Pan, Design of Pure Aluminum Laminates with Heterostructures for Extraordinary Strength-Ductility Synergy, J. Mater. Sci. Technol., 2022, 100, p 193–205.

H. Wu and G. Fan, An Overview of Tailoring Strain Delocalization for Strength-Ductility Synergy, Prog. Mater. Sci., 2020, 113, p 100675.

C.X. Huang, Y.F. Wang, X.L. Ma, S. Yin, H.W. Höppel, M. Göken, X.L. Wu, H.J. Gao, and Y.T. Zhu, Interface Affected Zone for Optimal Strength and Ductility in Heterogeneous Laminate, Mater. Today, 2018, 21(7), p 713–719.

J. Zhao, K. Wang, L. Lv, and G. Liu, Evolution and Distribution of Geometrically Necessary Dislocations for TA15 Titanium Alloy Sheets During the Hot Tensile Process, JOM, 2019, 71(7), p 2303–2312.

Acknowledgments

This work was financially supported by Program for Heilongjiang Touyan Team (No. HITTY-20190015), National Natural Science Foundation of China (No. 52205345).

Author information

Authors and Affiliations

Contributions

JZ: Conceptualization, Writing—original draft. BW: Formal analysis, Data curation. TG: Formal analysis, Writing—review and editing. KW: Writing—review and editing. DW: Supervision, Writing—review and editing. GL: Funding acquisition, Project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, J., Wang, B., Gao, T. et al. Modeling the Effect of Diffusion Layer and Interface on the Flow Stress for a Ni/Al Laminate Prepared by Vacuum Hot Pressing. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09309-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09309-6