Abstract

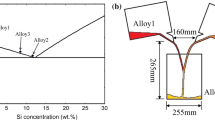

The microstructure and mechanical properties of hypereutectic Ai-Si alloys prepared by serpentine channel with spoiler were investigated. The flow state of the melt during the slurry preparation by the serpentine channel was simulated. The Al-Si alloy with the spoiler was superior to that without the spoiler at identical pouring conditions. The microstructure of the hypereutectic Ai-Si alloy was composed of the primary Si and Al-Si eutectic phases. The flow direction of the alloy slurry was disorganized because of the stirring effect of the spoiler, which improved the nuclei exfoliation and spherical growth of the primary Si. The spoiler refined the primary Si grains, and enhanced the mechanical properties of the Al-Si alloy. As the pouring temperature decreased from 746 to 701 °C, the size of the primary Si grains gradually decreased, and the tensile strength of the Al-Si alloy increased. The equivalent diameter of the primary Si grains could be reduced to 21.2 μm, and the tensile strength could be increased to 298 MPa under a pouring temperature of 701 °C.

Similar content being viewed by others

References

R. Haghayeghi and G. Timelli, An Investigation on Primary Si Refinement by Sr and Sb Additions in a Hypereutectic Al-Si Alloy, Mater. Lett., 2021, 283, p 128779.

G.L. Mao, H. Yan, C.C. Zhu, Z. Wu, and W.L. Gao, The Varied Mechanisms of Yttrium (Y) Modifying a Hypoeutectic Al-Si Alloy Under Conditions of Different Cooling Rates, J. Alloy. Compd., 2019, 806, p 909–916.

X.Z. Zhu, S.H. Wang, X.X. Dong, X.F. Liu, and S.X. Ji, Morphologically Templated Nucleation of Primary Si on AlP in Hypereutectic Al-Si Alloys, J. Mater. Sci. Technol., 2022, 100, p 36–45.

E. Damavandi, S. Nourouzi, S.M. Rabiee, R. Jamaati, A.A. Tiamiyu, and J.A. Szpunar, Effects of Prior ECAP Process on the Dynamic Impact Behaviors of Hypereutectic Al-Si Alloy, Mater. Sci. Eng. A-Struct., 2020, 793, p 139902.

H.R. Kotadia, G. Gibbons, A. Das, and P.D. Howes, A Review of Laser Powder Bed Fusion Additive Manufacturing of Aluminium Alloys: Microstructure and Properties, Addit. Manuf., 2021, 46, p 102155.

Y.K. Li, S.Y. Xi, G.D. Ma, Y. Xiao, L. Li, Z.T. Yuan, Y.H. He, R.F. Zhou, and Y.H. Jiang, Understanding the Influencing Mechanism of Sub-Micron Sized TiB2p on the Microstructures and Properties of Rheological Squeeze Casting Hypereutectic Al–Si Alloys, J. Mater. Res. Technol., 2021, 14, p 57–68.

C. Sumalatha, P.V.C.S. Rao, V.V.S. Rao, and M.S.K. Deepak, Influence of Grain Refiner, Modifier and Graphene on the Dry Sliding Wear of Hypereutectic Al-Si Alloys, Metallogr. Microstruct., 2022, 11(2), p 234–244.

Y.J. Xu, Y. Deng, D. Casari, R.H. Mathiesen, X.F. Liu, and Y.J. Li, Revealing the Nucleation Kinetics of Primary Si Particles in Hypereutectic Al-Si Alloys Under the Influence of P Inoculation, J. Mater. Sci., 2020, 55(32), p 15621–15635.

M.J. Li, N.K. Omura, Y. Murakami, I. Matsui, and S.J. Tada, A Comparative Study of the Primary Phase Formation in Al-7 wt% Si and Al-17 wt% Si Alloys Solidified by Electromagnetic Stirring Processing, Mater. Today. Commun., 2020, 24, p 101146.

W.Z. Yu, Y. Xue, J. Mei, X.Z. Zhou, M.L. Xiong, and S.F. Zhang, Segregation and Removal of Transition Metal Impurities During the Directional Solidification Refining of Silicon with Al-Si Solvent, J. Alloy. Compd., 2019, 805, p 198–204.

R.G. Guan, Z.Y. Zhao, C.S. Lee, Q.S. Zhang, and C.M. Liu, Effect of Wavelike Sloping Plate Rheocasting on Microstructures of Hypereutectic Al-18 pct Si-5 pct Fe Alloys, Metall. Mater. Trans. B, 2012, 43(2), p 337–343.

D.K. Yadav and I. Chakrabarty, Effect of Cooling Slope Casting and Partial Remelting Treatment on Microstructure and Mechanical Properties of A319-xMg2Si In-Situ Composites, Mat. Sci. Eng. A-Struct., 2020, 791, p 139790.

P. Das, S.K. Samanta, R. Das, and P. Dutta, Optimization of Degree of Sphericity of Primary Phase During Cooling Slope Casting of A356 Al Alloy: Taguchi Method and Regression Analysis, Measurement, 2014, 55, p 605–615.

L.W. Chen, J. Li, W.P. Chen, X.L. Pei, H. Hou, and Y.H. Zhao, Comprehensive Assessment and Multiple-Response Optimization of Serpentine Channel Pouring Process for Achieving High-Quality Semi-Solid Slurry, J. Mater. Res. Technol., 2023, 24, p 3839–3852.

L.W. Chen, Y.H. Zhao, F. Yan, and H. Hou, Statistical Investigations of Serpentine Channel Pouring Process Parameters on Semi-Solid ZL101 Aluminum Alloy slurry using response surface Methodology, J. Alloy. Compd., 2017, 725, p 673–683.

Z.K. Zheng, Y.J. Ji, W.M. Mao, R. Yue, and Z.Y. Liu, Influence of Rheo-Diecasting Processing Parameters on Microstructure and Mechanical Properties of Hypereutectic Al-30% Si Alloy, Trans. Nonferrous Metal. Soc., 2017, 27(6), p 1264–1272.

Z.K. Zheng, W.M. Mao, Z.Y. Liu, D. Wang, and R. Yue, Refinement of primary Si grains in Al-20%Si alloy slurry through serpentine channel pouring process, Int. J. Min. Met. Mater., 2016, 23(5), p 572–580.

P.Y. Yan, W.M. Mao, J. Fan, B.K. Wang, and Y.B. Liu, Microstructural Evolution, Segregation and Fracture Behavior of A390 Alloy Prepared by Combined Rheo-HPDC Processing and Sr-Modifier, J. Alloy. Compd., 2020, 835, p 155297.

Z.Y. Liu, W.M. Mao, T. Wan, G.T. Cui, and W.P. Wang, Study on Semi-Solid A380 Aluminum Alloy Slurry Prepared by Water-Cooling Serpentine Channel and Its Rheo-Diecasting, Met. Mater. Int., 2021, 27(7), p 2067–2077.

S. O’Regan, P.J. Frawley, and O. Shardt, The Effects of Particle Shape, Orientation, and Reynolds Number on Particle-Wall Collisions, Comput. Fluids, 2023, 266, p 106053.

Y. Bao and H. Wang, Numerical Study on Flow and Heat Transfer Characteristics of a Novel Tesla Valve with Improved Evaluation Method, Int. J. Heat Mass Tran., 2022, 187, p 122540.

I. Shamseddine, F. Pennec, P. Biwole, and F. Fardoun, Supercooling of Phase Change Materials: A Review, Renew. Sust. Energ. Rev., 2022, 158, p 112172.

B. Zhou, Z.Y. Qiu, K.P. Chen, C. Xu, and Z.Y. Wang, Microstructure Properties, and Numerical Simulation of Semi-Solid Aluminum Alloy under Planetary Stirring Process, Materials, 2022, 15(9), p 3009.

P. Jin, Y.B. Liu, and Q.J. Sun, Evolution of Crystallographic Orientation, Columnar to Equiaxed Transformation and Mechanical Properties Realized by Adding TiCps in Wire and Arc Additive Manufacturing 2219 Aluminum Alloy, Addit. Manuf., 2021, 39, p 101878.

T. Aoyama and K. Kuribayashi, Influence of Undercooling on Solid/Liquid Interface Morphology in Semiconductors, Acta Mater., 2000, 48(14), p 3739–3744.

C.Y. Tan, M.A.A.M. Salleh, X.F. Tan, H. Yasuda, N. Saud, M.I.I. Ramli, and K. Nogita, Properties of Sn-3 wt%Ag-5 wt%Cu Alloys with Cu6Sn5 Intermetallics Grain Refined by Mg, Mater. Today. Commun., 2022, 31, p 103221.

C. Xu, H. Wang, Y. Yang, and Q. Jiang, Effect of Al-P-Ti-TiC-Nd2O3 Modifier on the Microstructure and Mechanical Properties of Hypereutectic Al-20wt.%Si Alloy, Mater. Sci. Eng. A, 2007, 452, p 341–346.

R. Haghayeghi, L.C. Paula, and E.J. Zoqui, Comparison of Si Refinement Efficiency of Electromagnetic Stirring and Ultrasonic Treatment for a Hypereutectic Al-Si Alloy, J. Mater. Eng. Perform., 2017, 26, p 1900–1907.

M.H. Abdelaziz, A.M. Samuel, H.W. Doty, S. Valtierra, and F.H. Samuel, Effect of Additives on the Microstructure and Tensile Properties of Al-Si Alloys, J. Mater. Res. Technol., 2019, 8(2), p 2255–2268.

G.D. Niu, Y. Wang, L.J. Zhu, J.W. Ye, and J. Mao, Fluidity of Casting Al-Si Series Alloys for Automotive Light-Weighting: A Systematic Review, Mater. Sci. Tech-Lond., 2022, 38(13), p 902–911.

X. Zhang, H. Xu, T. Chen, C.S. Wang, Y.L. Wang, L.J. Xu, and H.W. Li, Forming Properties and Microstructure of Al-Cu Alloy Prepared by Liquid-Die Forging, J. Cent. South. Univ., 2022, 29(1), p 60–79.

M. Li, Y.D. Li, and H.W. Zhou, Effects of Pouring Temperature on Microstructure and Mechanical Properties of the A356 Aluminum Alloy Diecastings, Mat. Res., 2020, 23(1), p e20190676.

M. Li, N. Omura, Y. Murakami, I. Matsui, and S. Tada, A Comparative Study of the Primary Phase Formation in Al-7 wt% Si and Al-17 wt% Si Alloys Solidified by Electromagnetic Stirring Processing, Mater. Today Commun., 2020, 24, p 101146.

M.M. Shehata, S. El-Hadad, M.E. Moussa, and M. El-Shennawy, Optimizing the Pouring Temperature for Semisolid Casting of a Hypereutectic Al–Si Alloy Using the Cooling Slope Plate Method, Int. J. Metalcast., 2021, 15, p 488–499.

M. Nowak, L. Bolzoni, and N.H. Babu, The Effect of Nb-B Inoculation on Binary Hypereutectic and Near-Eutectic LM13 Al-Si Cast Alloys, J. Alloy. Compd., 2015, 641, p 22–29.

Acknowledgment

This work was supported financially by the Scientific and Technological Project of Henan Province (212102210350), the Research Foundation for Advanced Talents of Henan University of Technology (2019BS052), and Henan Province science and technology research project (222102220018).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, D., Jiang, C., Cai, G. et al. Refinement of Primary Si in Hypereutectic Al-Si Alloy by Serpentine Channel with Spoiler. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09258-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09258-0