Abstract

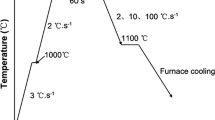

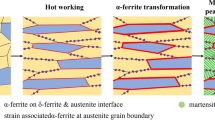

Microstructure evolution on the surface of Fe-20Mn-6Al-0.6C-0.15Si austenitic low-density steel was studied by comparing with the microstructure at the core. In the present study, the austenite grain growth was in situ observed using laser scanning confocal microscope (LSCM). The microstructure of specimens on surface and at core was analyzed after LSCM experiments. The distribution of Mn and Al along axial direction was analyzed. The results show that the volatilization of Mn on the specimen surface during isothermal holding at high temperatures varying from 900 to 1200 °C results in a low stability of the austenite on the specimen surface, leading to the transformation of less stable austenite to ferrite during subsequent cooling process. The ferrite fraction on the specimen surface increases with isothermal temperature, indicating more Mn volatilization at higher temperature. In addition, because Mn volatilizes during isothermal holding at high temperatures, the austenite grain growth on the surface is different from that at the core.

Similar content being viewed by others

References

K.T. Park, Tensile Deformation of Low-Density Fe-Mn-Al-C Austenitic Steels at Ambient Temperature, Scr. Mater., 2013, 68(6), p 375–379.

D.W. Suh and N.J. Kim, Low-Density Steels, Scr. Mater., 2013, 68(6).

S. Hu, Z. Zheng, W. Yang, and H. Yang, Fe-Mn-C-Al Low-Density Steel for Structural Materials: A Review of Alloying, Heat Treatment, Microstructure, and Mechanical Properties, Steel Res. Int., 2022, 93(9), p 2200191.

Y. Feng, R. Song, Z. Pei, R. Song, and G. Dou, Effect of Aging Isothermal Time on the Microstructure and Room-Temperature Impact Toughness of Fe-24.8Mn-7.3Al-1.2C Austenitic Steel with κ-Carbides Precipitation, Met. Mater. Int., 2018, 24(5), p 1012–1023.

S. Chen, R. Rana, A. Haldar, and R.K. Ray, Current State of Fe-Mn-Al-C Low Density Steels, Prog. Mater. Sci., 2017, 89, p 345–391.

R. Rana, Low-Density Steels, JOM, 2014, 66(9), p 1730–1733.

B. Kim, S. Jeong, S.J. Park, J. Moon, and C. Lee, Roles of (Fe, Mn)3Al Precipitates and MBIP on the Hot Ductility Behavior of Fe-30Mn-9Al-0.9C Lightweight Steels, Met. Mater. Int., 2019, 25(4), p 1019–1026.

J. Zhang, Y. Jiang, C. Hu, G. Ji, C. Song, and Q. Zhai, Effect of Cr on Phase Transformation Behavior of Austenite in Fe-20Mn-9Al-1.2C-XCr Low-Density Steels During Isothermal Aging, Met. Mater. Int., 2022, 28(11), p 2583–2595.

P. Wan, H. Yu, F. Li, P. Gao, L. Zhang, and Z. Zhao, Hot Deformation Behaviors and Process Parameters Optimization of Low-Density High-Strength Fe-Mn-Al-C Alloy Steel, Met. Mater. Int., 2022, 28(10), p 2498–2512.

Y.P. Li, R.B. Song, E.D. Wen, and F.Q. Yang, Hot Deformation and Dynamic Recrystallization Behavior of Austenite-Based Low-Density Fe-Mn-Al-C Steel, Acta Metall. Sin. Engl. Lett., 2016, 29(5), p 441–449.

K.T. Park, S.W. Hwang, C.Y. Son, and J.K. Lee, Effects of Heat Treatment on Microstructure and Tensile Properties of a Fe-27Mn-12Al-0.8C Low-Density Steel, JOM, 2014, 66(9), p 1828–1836.

H. Jung, G. Lee, M. Koo, H. Song, W.S. Ko, and S.S. Sohn, Effects of Mn Segregations on Intergranular Fracture in a Medium-Mn Low-Density Steel, Steel Res. Int., 2023, 94(2), p 2200240.

I. Hwang, D. Kim, M. Kang, J.H. Kwak, and Y.M. Kim, Resistance Spot Weldability of Lightweight Steel with a High Al Content, Met. Mater. Int., 2017, 23(2), p 341–349.

S. Guo, H. Zhu, J. Zhao, M. Song, J. Li, and Z. Xue, Effects of Nitrogen on the Microstructure and Mechanical Properties of Fe-28Mn-10Al-0.8 C Low-Density Steel, Steel Res. Int., 2022, 93(8), p 2100643.

Y.T. Huo, Y.L. He, N.Q. Zhu, M.L. Ding, R.D. Liu, and Y. Zhang, Deformation Mechanism Investigation on Low Density 18Mn Steels under Different Solid Solution Treatments, Metals., 2021, 11(9), p 1497.

S.W. Park, J.Y. Park, K.M. Cho, J.H. Jang, S.J. Park, J. Moon, T.H. Lee, and J.H. Shin, Effect of Mn and C on Age Hardening of Fe-Mn-Al-C Lightweight Steels, Met. Mater. Int., 2019, 25(3), p 683–696.

D.T. Pierce, D.M. Field, K.R. Limmer, T. Muth, and K.M. Sebeck, Hot Deformation Behavior of an Industrially Cast Large Grained Low Density Austenitic Steel, Mater. Sci. Eng. A, 2021, 825, p 141785.

J. Pang, Z. Zhou, Z. Zhao, D. Tang, J. Liang, and Q. He, Tensile Behavior and Deformation Mechanism of Fe-Mn-Al-C Low Density Steel with High Strength and High Plasticity, Metals., 2019, 9(8), p 897.

J. Lee, S. Park, H. Kim, S.J. Park, K. Lee, M.Y. Kim, P.P. Madakashira, and H.N. Han, Simulation of κ-Carbide Precipitation Kinetics in Aged Low-Density Fe-Mn-Al-C Steels and Its Effects on Strengthening, Met. Mater. Int., 2018, 24(4), p 702–710.

D. Xu, C. Ji, H. Zhao, D. Ju, and M. Zhu, A New Study on the Growth Behavior of Austenite Grains during Heating Processes, Sci. Rep., 2017, 7(1), p 3968–4013.

Q. Gao, F. Qu, H. Zhang, and Q. Huo, Austenite Grain Growth in Alumina-Forming Austenitic Steel, J. Mater. Res., 2016, 31(12), p 1732–1740.

F. Meng, J. Wang, J. Guo, K. Fu, M. Zhao, Z. Wang, and Z. Xu, Growth Behavior and Kinetics of Austenite Grain in Low-Carbon High-Strength Steel with Copper, Mater. Res. Express, 2021, 8(9), p 96504.

W. Mu, P. Hedström, H. Shibata, P.G. Jönsson, and K. Nakajima, High-Temperature Confocal Laser Scanning Microscopy Studies of Ferrite Formation in Inclusion-Engineered Steels: A Review, JOM, 2018, 70(10), p 2283–2295.

W. Wang, Z. An, S. Luo, and M. Zhu, In-Situ Observation of Peritectic Solidification of Fe-Mn-Al-C Steel with Medium Manganese, J. Alloys Compd., 2022, 909, p 164750.

J. Tian, H. Wang, M. Zhu, M. Zhou, Q. Zhang, X. Su, A. Guo, and G. Xu, Improving Mechanical Properties in High-Carbon Pearlitic Steels by Replacing Partial V with Nb, Mater. Sci. Eng. A, 2022, 834, p 142622.

N. Yan, S. Yu, and Y. Chen, In Situ Observation of Austenite Grain Growth and Transformation Temperature in Coarse Grain Heat Affected Zone of Ce-Alloyed Weld Metal, J. Rare Earths, 2017, 35(2), p 203–210.

Q. Zhang, H. Wang, M. Zhu, X. Su, M.I. Zhou, and X. Guang, In-Situ Observation on Austenite Grain Growth of a Nb Microalloyed High-Carbon Steel, J. Iron Steel Res., 2022, 34(08), p 840–847.

N. Fuchs, P. Krajewski, and C. Bernhard, In-Situ Observation of Austenite Grain Growth in Plain Carbon Steels by Means of High-Temperature Laser Scanning Confocal Microscopy, BHM Berg-Hüttenmänn. Monatshefte, 2015, 160(5), p 214–220.

R.K. Wild, Vacuum Annealing of Stainless Steel at Temperatures between 770 and 1470K, Corros. Sci., 1974, 14(10), p 575–586.

A.F. Smith and R. Hales, Diffusion of Manganese in Type 316 Austenitic Stainless Steel, Met. Sci., 1975, 1(9), p 181–184.

N. Fuchs and C. Bernhard, Potential and Limitations of Direct Austenite Grain Growth Measurement by Means of HT-LSCM, Mater. Today Commun., 2021, 28, p 102468.

C.G. de Andrés, F.G. Caballero, C. Capdevila and M.D. San, Revealing Austenite Grain Boundaries by Thermal Etching: Advantages and Disadvantages, Mater Charact, 2002, 49(2), p 121–127.

B. Aashranth, G. Shankar, D. Samantaray, and S. Suwas, The Role of Hot Deformation Texture on Dynamic Transformation of Austenite to Ferrite in a 9%Cr Alloy Steel, JOM, 2022, 74(6), p 2377–2385.

S. Martin, O. Fabrichnaya, and D. Rafaja, Prediction of the Local Deformation Mechanisms in Metastable Austenitic Steels from the Local Concentration of the Main Alloying Elements, Mater. Lett., 2015, 159, p 484–488.

J. Chu, Y. Bao, X. Li, M. Wang, and F. Gao, Kinetic Study of Mn Vacuum Evaporation from Mn Steel Melts, Sep. Purif. Technol., 2021, 255, p 117698.

G. Coccia Lecis, C. Lenardi, and A. Sabatini, The Effect of Mn-Depleted Surface Layer on the Corrosion Resistance of Shape Memory Fe-Mn-Si-Cr Alloys, Metall. Mater. Trans. A, 1997, 28(5), p 1219–1222.

A.M. De Sousa Malafaia, L. Latu-Romain, and Y. Wouters, High Temperature Oxidation Resistance Improvement in an FeMnSiCrNi Alloy by Mn-Depletion under Vacuum Annealing, Mater. Lett., 2019, 241, p 164–167.

B. Qian, H. Peng, and Y. Wen, A Novel Sandwich Fe-Mn Damping Alloy with Ferrite Shell Prepared by Vacuum Annealing, Smart Mater. Struct., 2018, 27(4), p 045005.

F. Lan, C. Zhuang, C. Li, J. Chen, G. Yang, and H. Yao, Study on Manganese Volatilization Behavior of Fe-Mn-C-Al Twinning-Induced Plasticity Steel, High Temp. Mater. Process., 2021, 40(1), p 461–470.

S. Catteau, T. Sourmail, and A. Moine, Dilatometric Study of Phase Transformations in Steels: Some Issues, Mater. Perform. Charact., 2016, 5(5), p 564–584.

Y. Tomota, N. Sekido, S. Harjo, T. Kawasaki, W. Gong, and A. Taniyama, In Situ Observations of Transformation Behavior upon Heating for a 1.5Mn-1.5Si-0.2C Steel-Comparison Between Neutron Diffraction, XRD EBSD Dilatometry-ISIJ Int., 2017, 57(12), p 2237–2244.

P. Jimbert, T. Guraya, I. Kaltzakorta, T. Gutiérrez, R. Elvira, and K.L. Tafaghodi, Different Phenomena Encountered during Dilatometry of Low-Density Steels, J. Mater. Eng. Perform., 2022, 1, p 1–1.

J. Chu and Y. Bao, Volatilization Behavior of Manganese from Molten Steel with Different Alloying Methods in Vacuum, Metals, 2020, 10(10), p 1348.

S. Khare and P. Mahajan, Controlling the Ferrite Kinetics in Fe-C-Mn Alloys, Met. Mater. Int., 2015, 21(3), p 446–452.

M. Khorrami, A.Z. Hanzaki, H.R. Abedi, M. Moallemi, J. Mola, and G. Chen, On the Effect of Mn-Content on the Strength-Ductility Balance in Ni-Free High N Transformation Induced Plasticity Steels, Mater. Sci. Eng. A, 2021, 814, p 141260.

H. Fang, S. Van Der Zwaag, and N.H. Van Dijk, A Novel 3D Mixed-Mode Multigrain Model with Efficient Implementation of Solute Drag Applied to Austenite-Ferrite Phase Transformations in Fe-C-Mn Alloys, Acta Mater., 2021, 212, p 116897.

Easterling, K.E. Phase Transformations in Metals and Alloys, Third Edition (Revised Reprint), Phase Transformations in Metals and Alloys, Third Edition (Revised Reprint), (1992).

M. Bhattacharyya, B. Langelier, G.R. Purdy, and H.S. Zurob, Effect of Mn and C on Grain Growth in Mn Steels, Metall. Mater. Trans. Phys. Metall. Mater. Sci., 2019, 50(2), p 905–914.

A. Saeed-Akbari, J. Imlau, U. Prahl, and W. Bleck, Derivation and Variation in Composition-Dependent Stacking Fault Energy Maps Based on Subregular Solution Model in High-Manganese Steels, Metall. Mater. Trans. A, 2009, 40(13), p 3076–3090.

J.K. Kim and B.C. De Cooman, Stacking Fault Energy and Deformation Mechanisms in Fe-XMn-0.6C-YAl TWIP Steel, Mater. Sci. Eng. A, 2016, 676, p 216–231.

M. Bhattacharyya, Y. Brechet, G.R. Purdy, and H.S. Zurob, Austenite Grain Growth in High Manganese Steels, Metall. Mater. Trans. A, 2019, 50(12), p 5760–5766.

Acknowledgments

The authors gratefully acknowledge the financial supports from the National Natural Science Foundation of China (No. U20A20270), the Joint Development Project from Lianyuan Iron and Steel Company Limited (2020-13#) and China Postdoctoral Science Foundation (No. 2022M722486). We would like to thank Dr. Zhen Wang at the Analytical & Testing Center of Wuhan University of Science and Technology for the help on EBSD analyses.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, Q., Chen, G., Shen, Y. et al. Microstructure Evolution on the Surface of Fe-20Mn-6Al-0.6C-0.15Si Austenitic Low-Density Steel during Heat Treatment. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08803-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08803-7