Abstract

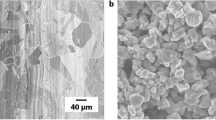

CoCrFeNi alloy is the most well-known four-component equiatomic alloy. In addition, it has a low-cost composition among HEAs. Four-component alloys are considered semi-HEAs. Therefore, a five-component HEA design was made by adding another metal to the main composition of CoCrFeNi. As the fifth metal, two metals such as Al and Ti, which are relatively low in cost and have the potential to improve properties, were chosen. For this purpose, in this study, the effect of Al and Ti on CoCrFeNi main alloy was investigated by producing three different samples as CoCrFeNi, CoCrFeNiAl, and CoCrFeNiTi. The alloys with three different compositions (used three different samples) were successfully produced by the mechanical alloying method. Although Al and Ti have the possibility of intermetallic with other metals in the alloy, such a formation was not observed during mechanical alloying, and it was observed that all metals were homogeneously distributed in the alloy. The microhardness results indicated that CoCrFeNiAl and CoCrFeNiTi samples had similar hardness values. While the hardness of the CoCrFeNi sample was 136 HV, the hardness of the CoCrFeNiAl sample was 262 HV. However, the hardness of the CoCrFeNiTi sample decreased significantly. The hardness of the CoCrFeNiTi sample was measured as 269 HV. It was observed that the addition of Ti and Al to the base alloy was increased a significant change in hardness. It has been observed that Ti supplementation has a more positive effect on improving corrosion properties. It is seen that the corrosion potentials shift toward more negative potentials with the addition of Al and Ti to the CoCrFeNi (−194 mV) alloy (−306 and −224 mV for CoCrFeNiAl and CoCrFeNiTi, respectively). When the surface morphologies of the alloys are compared after corrosion; the damage to the alloy surfaces increases due to the negative Ecorr value in CoCrFeNiAl and CoCrFeNiTi alloys compared to the master alloy. However, the high corrosion current density (12.69 µA/cm2) in the CoCrFeNiTi sample caused much more damage to this alloy.

Graphical Abstract

Similar content being viewed by others

References

Y. Shi, L. Collins, R. Feng, C. Zhang, N. Balke, P.K. Liaw, and B. Yang, Homogenization of AlxCoCrFeNi High-Entropy Alloys with Improved Corrosion Resistance, Corros. Sci., 2018, 133, p 120–131.

T. I-u-H, Evaluation of Corrosion Performance of Two Mn-Containing Stainless Steel Alloys, Int. J. Mater. Res., 2014, 105, p 386–391.

A. Dalmau, C. Richard, and A. Igual-Muñoz, Degradation Mechanisms in Martensitic Stainless Steels: Wear, Corrosion and Tribocorrosion Appraisal, Tribol. Int., 2018, 121, p 167–179.

L. Jinlong, L. Tongxiang, and W. Chen, Surface Enriched Molybdenum Enhancing the Corrosion Resistance of 316L Stainless Steel, Mater. Lett., 2016, 171, p 38–41.

Z. Wang, Y. Huang, Y. Yang, J. Wang, and C. Liu, Atomic-Size Effect and Solid Solubility of Multicomponent Alloys, Scr. Mater., 2015, 94, p 28–31.

K.W. Chan and S.C. Tjong, Effect of Secondary Phase Precipitation on the Corrosion Behavior of Duplex Stainless Steels, Materials, 2014, 7, p 5268–5304.

M.-H. Tsai and J.-W. Yeh, High-Entropy Alloys: A Critical Review, Mater. Res. Lett., 2014, 2, p 107–123.

Ö. Güler, T. Şimşek, İ Özkul, B. Avar, C.A. Canbay, A.K. Chattopadhyay, and S.H. Güler, Investigation of Shape Memory Characteristics and Production of HfZrTiFeMnSi High Entropy Alloy by Mechanical Alloying Method, Curr. Appl. Phys., 2022, 33, p 1–11.

Y. Shi, B. Yang, X. Xie, J. Brechtl, K.A. Dahmen, and P.K. Liaw, Corrosion of Al xCoCrFeNi High-Entropy Alloys: Al-Content and Potential Scan-Rate Dependent Pitting Behavior, Corros. Sci., 2017, 119, p 33–45.

Y. Zhang, X. Yang, and P. Liaw, Alloy Design and Properties Optimization of High-Entropy Alloys, JOM, 2012, 64, p 830–838.

Y. Zhao, J. Qiao, S. Ma, M. Gao, H. Yang, M. Chen, and Y. Zhang, A Hexagonal Close-Packed High-Entropy Alloy: The Effect of Entropy, Mater. Des., 2016, 96, p 10–15.

J. He, W. Liu, H. Wang, Y. Wu, X. Liu, T. Nieh, and Z. Lu, Effects of Al Addition on Structural Evolution and Tensile Properties of the FeCoNiCrMn High-Entropy Alloy System, Acta Mater., 2014, 62, p 105–113.

Z. Tang, T. Yuan, C.-W. Tsai, J.-W. Yeh, C.D. Lundin, and P.K. Liaw, Fatigue Behavior of a Wrought Al0.5CoCrCuFeNi Two-Phase High-Entropy Alloy, Acta Mater., 2015, 99, p 247–258.

D. Xiao, P. Zhou, W. Wu, H. Diao, M. Gao, M. Song, and P. Liaw, Microstructure, Mechanical and Corrosion Behaviors of AlCoCuFeNi-(Cr, Ti) High Entropy Alloys, Mater. Des., 2017, 116, p 438–447.

S.-P. Wang and J. Xu, TiZrNbTaMo High-Entropy Alloy Designed for Orthopedic Implants: As-Cast Microstructure and Mechanical Properties, Mater. Sci. Eng. C, 2017, 73, p 80–89.

E.P. George, W. Curtin, and C.C. Tasan, High Entropy Alloys: A Focused Review of Mechanical Properties and Deformation Mechanisms, Acta Mater., 2020, 188, p 435–474.

S. Yin, W. Li, B. Song, X. Yan, M. Kuang, Y. Xu, K. Wen, and R. Lupoi, Deposition of FeCoNiCrMn High Entropy Alloy (HEA) Coating via Cold Spraying, J. Mater. Sci. Technol., 2019, 35, p 1003–1007.

A. Verma, P. Tarate, A. Abhyankar, M. Mohape, D. Gowtam, V. Deshmukh and T. Shanmugasundaram, High Temperature Wear in CoCrFeNiCux High Entropy Alloys: The Role of Cu, Scr. Mater., 2019, 161, p 28–31.

Y. Tian, S. Sun, H. Lin, and Z. Zhang, Fatigue Behavior of CoCrFeMnNi High-Entropy Alloy under Fully Reversed Cyclic Deformation, J. Mater. Sci. Technol., 2019, 35, p 334–340.

M.A. Hemphill, T. Yuan, G. Wang, J. Yeh, C. Tsai, A. Chuang and P. Liaw, Fatigue Behavior of Al0.5CoCrCuFeNi High Entropy Alloys, Acta Mater., 2012, 60, p 5723–5734.

Z. Wu, H. Bei, G.M. Pharr, and E.P. George, Temperature Dependence of the Mechanical Properties of Equiatomic Solid Solution Alloys with Face-Centered Cubic Crystal Structures, Acta Mater., 2014, 81, p 428–441.

Q. Ye, K. Feng, Z. Li, F. Lu, R. Li, J. Huang, and Y. Wu, Microstructure and Corrosion Properties of CrMnFeCoNi High Entropy Alloy Coating, Appl. Surf. Sci., 2017, 396, p 1420–1426.

A. Raphel, S. Kumaran, K.V. Kumar, and L. Varghese, Oxidation and Corrosion Resistance of AlCoCrFeTi High loy, Mater. Today Proc., 2017, 4, p 195–202.

T. Şimşek, İ Özkul, C.A. Canbay, B. Avar, T. Şimşek, S.H. Güler, S. Özcan, Ö. Güler, and A.K. Chattopadhyay, Effect of Cu, Sn and Sb Addition on the Structural, Thermal and Magnetic Properties of Body-Centered Cubic Structured CoNiMnGaSi High Entropy Alloy, Appl. Phys. A, 2022, 128, p 543.

T.-T. Shun, L.-Y. Chang, and M.-H. Shiu, Microstructure and Mechanical Properties of Multiprincipal Component CoCrFeNiMox Alloys, Mater. Charact., 2012, 70, p 63–67.

Z. Tang, M.C. Gao, H. Diao, T. Yang, J. Liu, T. Zuo, Y. Zhang, Z. Lu, Y. Cheng, and Y. Zhang, Aluminum Alloying Effects on Lattice Types, Microstructures, and Mechanical Behavior of High-Entropy Alloys Systems, JOM, 2013, 65, p 1848–1858.

Y.-J. Hsu, W.-C. Chiang, and J.-K. Wu, Corrosion Behavior of FeCoNiCrCux High-Entropy Alloys in 3.5% Sodium Chloride Solution, Mater. Chem. Phys., 2005, 92, p 112–117.

S. Shuang, Z. Ding, D. Chung, S. Shi, and Y. Yang, Corrosion Resistant Nanostructured Eutectic High Entropy Alloy, Corros. Sci., 2020, 164, p 108315.

G. Salishchev, M. Tikhonovsky, D. Shaysultanov, N. Stepanov, A. Kuznetsov, I. Kolodiy, A. Tortika, and O. Senkov, Effect of Mn and V on Structure and Mechanical Properties of High-Entropy Alloys Based on CoCrFeNi System, J. Alloys Compd., 2014, 591, p 11–21.

R. Sokkalingam, S. Mishra, S.R. Cheethirala, V. Muthupandi, and K. Sivaprasad, Enhanced Relative Slip Distance in Gas-Tungsten-Arc-Welded Al 0.5 CoCrFeNi High-Entropy Alloy, Metall. Mater. Trans. A., 2017, 48, p 3630–3634.

Y.-F. Kao, T.-D. Lee, S.-K. Chen, and Y.-S. Chang, Electrochemical Passive Properties of AlxCoCrFeNi (x= 0, 0.25, 0.50, 1.00) Alloys in Sulfuric Acids, Corros. Sci., 2010, 52, p 1026–1034.

C. Lee, Y. Chen, C. Hsu, J. Yeh, and H. Shih, Enhancing Pitting Corrosion Resistance of AlxCrFe1.5MnNi0.5 High-Entropy Alloys by Anodic Treatment in Sulfuric Acid, Thin Solid Films, 2008, 517, p 1301–1305.

C.-M. Lin, H.-L. Tsai, and H.-Y. Bor, Effect of Aging Treatment on Microstructure and Properties of High-Entropy Cu0.5CoCrFeNi Alloy, Intermetallics, 2010, 18, p 1244–1250.

S.-T. Chen, W.-Y. Tang, Y.-F. Kuo, S.-Y. Chen, C.-H. Tsau, T.-T. Shun, and J.-W. Yeh, Microstructure and Properties of Age-Hardenable AlxCrFe1.5MnNi0.5 Alloys, Mater. Sci. Eng. A, 2010, 527, p 5818–5825.

M.-H. Chuang, M.-H. Tsai, W.-R. Wang, S.-J. Lin, and J.-W. Yeh, Microstructure and Wear Behavior of AlxCo1.5CrFeNi1.5Tiy High-Entropy Alloys, Acta Mater., 2011, 59, p 6308–6317.

M.-H. Hsieh, M.-H. Tsai, W.-J. Shen, and J.-W. Yeh, Structure and Properties of Two Al–Cr–Nb–Si–Ti High-Entropy Nitride Coatings, Surf. Coat. Technol., 2013, 221, p 118–123.

C.-Y. Hsu, T.-S. Sheu, J.-W. Yeh, and S.-K. Chen, Effect of Iron Content on Wear Behavior of AlCoCrFexMo0.5Ni High-Entropy Alloys, Wear, 2010, 268, p 653–659.

C. Huang, Y. Zhang, J. Shen, and R. Vilar, Thermal Stability and Oxidation Resistance of Laser Clad TiVCrAlSi High Entropy Alloy Coatings on Ti–6Al–4V Alloy, Surf. Coat. Technol., 2011, 206, p 1389–1395.

J.C. Jiang and X.Y. Luo, in Advanced Materials Research (Trans Tech Publ, 2013), pp. 1115–1118.

C. Liu, H. Wang, S. Zhang, H. Tang, and A. Zhang, Microstructure and Oxidation Behavior of New Refractory High Entropy Alloys, J. Alloys Compd., 2014, 583, p 162–169.

A.D. Pogrebnjak, Structure and Properties of Nanostructured (Ti-Hf-Zr-V-Nb) N Coatings, J. Nanomater., 2013, 2013, p 1–12.

O. Senkov, S. Senkova, D. Dimiduk, C. Woodward, and D. Miracle, Oxidation Behavior of a Refractory NbCrMo0.5Ta0.5TiZr Alloy, J. Mater. Sci., 2012, 47, p 6522–6534.

R.K. Mishra and R. Shahi, A Systematic Approach for Enhancing Magnetic Properties of CoCrFeNiTi-Based High Entropy Alloys via Stoichiometric Variation and Annealing, J. Alloys Compd., 2020, 821, p 153534.

T. Fujieda, M. Chen, H. Shiratori, K. Kuwabara, K. Yamanaka, Y. Koizumi, A. Chiba, and S. Watanabe, Mechanical and Corrosion Properties of CoCrFeNiTi-Based High-Entropy Alloy Additive Manufactured Using Selective Laser Melting, Addit. Manuf., 2019, 25, p 412–420.

A. Erdoğan, M.S. Gök, and S. Zeytin, Analysis of the High-Temperature Dry Sliding Behavior of CoCrFeNiTi 0.5 Al x High-Entropy Alloys, Friction, 2020, 8, p 198–207.

U. Holzwarth and N. Gibson, The Scherrer Equation Versus the’Debye–Scherrer Equation’, Nat. Nanotechnol., 2011, 6, p 534–534.

V. Mote, Y. Purushotham, and B. Dole, Williamson–Hall Analysis in Estimation of Lattice Strain in Nanometer-Sized ZnO Particles, J. Theor. Appl. Phys., 2012, 6, p 6.

D. Hull and D.J. Bacon, Introduction to Dislocations, Butterworth-Heinemann, Oxford, 2001.

B. Avar, Structural, Thermal and Magnetic Characterization of Nanocrystalline Co65Ti25W5B5 Powders Prepared by Mechanical Alloying, J. Non-Cryst. Solids, 2016, 432, p 246–253.

C.-y Hsu, J.-W. Yeh, S.-K. Chen, and T.-T. Shun, Wear Resistance and High-Temperature Compression Strength of Fcc CuCoNiCrAl 0.5 Fe Alloy with Boron Addition, Metall. and Mater. Trans. A., 2004, 35, p 1465–1469.

A. Gali and E.P. George, Tensile Properties of High-and Medium-Entropy Alloys, Intermetallics, 2013, 39, p 74–78.

Z. Wu, H. Bei, F. Otto, G.M. Pharr, and E.P. George, Recovery, Recrystallization, Grain Growth and Phase Stability of a Family of FCC-Structured Multi-component Equiatomic Solid Solution Alloys, Intermetallics, 2014, 46, p 131–140.

W.-R. Wang, W.-L. Wang, S.-C. Wang, Y.-C. Tsai, C.-H. Lai, and J.-W. Yeh, Effects of Al Addition on the Microstructure and Mechanical Property of AlxCoCrFeNi High-Entropy Alloys, Intermetallics, 2012, 26, p 44–51.

T.-T. Shun, L.-Y. Chang, and M.-H. Shiu, Microstructures and Mechanical Properties of Multiprincipal Component CoCrFeNiTix Alloys, Mater. Sci. Eng. A, 2012, 556, p 170–174.

Y. Zhou, Y. Zhang, Y. Wang, and G. Chen, Solid Solution Alloys of Al Co Cr Fe Ni Ti x with Excellent Room-Temperature Mechanical Properties, Appl. Phys. Lett., 2007, 90, p 181904.

P. Cui, Y. Ma, L. Zhang, M. Zhang, J. Fan, W. Dong, P. Yu, G. Li, and R. Liu, Effect of Ti on Microstructures and Mechanical Properties of High Entropy Alloys Based on CoFeMnNi system, Mater. Sci. Eng. A, 2018, 737, p 198–204.

X. Wang, Y. Zhang, Y. Qiao, and G. Chen, Novel Microstructure and Properties of Multicomponent CoCrCuFeNiTix Alloys, Intermetallics, 2007, 15, p 357–362.

J. Rao, H. Diao, V. Ocelík, D. Vainchtein, C. Zhang, C. Kuo, Z. Tang, W. Guo, J. Poplawsky, and Y. Zhou, Secondary Phases in AlxCoCrFeNi High-Entropy Alloys: An In-Situ TEM Heating Study and Thermodynamic Appraisal, Acta Mater., 2017, 131, p 206–220.

Y.P. Wang, B.S. Li, and H.Z. Fu, Solid Solution or Intermetallics in a High-Entropy Alloy, Adv. Eng. Mater., 2009, 11, p 641–644.

F. Otto, Y. Yang, H. Bei, and E.P. George, Relative Effects of Enthalpy and Entropy on the Phase Stability of Equiatomic High-Entropy Alloys, Acta Mater., 2013, 61, p 2628–2638.

S. Singh, N. Wanderka, B. Murty, U. Glatzel, and J. Banhart, Decomposition in Multi-Component AlCoCrCuFeNi High-Entropy Alloy, Acta Mater., 2011, 59, p 182–190.

M. Gavgali, B. Dikici, and C. Tekmen, The Effect of SiCp Reinforcement on the Corrosion Behaviour of Al Based Metal Matrix Composites, Corros. Rev., 2006, 24, p 27–38.

C.B. Nascimento, U. Donatus, C.T. Ríos, M.C.L. de Oliveira, and R.A. Antunes, A Review on Corrosion of High Entropy Alloys: Exploring the Interplay Between Corrosion Properties, Alloy Composition, Passive Film Stability and Materials Selection. Mater. Res., 2022, 25.

Y. Qiu, S. Thomas, M.A. Gibson, H.L. Fraser, and N. Birbilis, Corrosion of high entropy alloys, npj Mater. Degrad., 2017, 1, p 15.

Acknowledgment

We would like to thank Munzur University (Project No. DPMUB022-01) for the financial support.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Say, Y., Dikici, B., Kaseem, M. et al. Production of CoCrFeNi(Al/Ti) High-Entropy Alloys by Mechanical Alloying: Optimization of Milling Time and Comparison of Corrosion Susceptibilities. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08380-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08380-9