Abstract

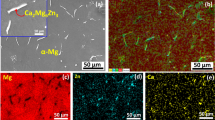

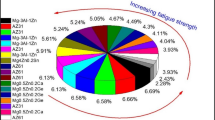

A new biodegradable Zn-2Cu-0.8 Mg-(Sr, Gd) zinc alloy was designed by using Zn-2Cu-0.8 Mg as the base alloy and adding microalloying elements Sr and Gd. After adding Sr and Gd, the corrosion resistance of Zn-2Cu-0.8 Mg zinc alloy was improved. The comprehensive mechanical properties of composite adding Sr and Gd are better than that of adding Sr alone, but lower than that of adding Gd alone. The corrosion rate of Zn-2Cu-0.8 Mg alloy decreased with Sr and Gd addition. The corrosion rate of Zn-2Cu-0.8 Mg is 0.304 mm/year, while that of Zn-2Cu-0.8 Mg-0.2Gd zinc alloy is the lowest, 0.185 mm/year in electrochemical test.

Similar content being viewed by others

References

X. Dandan, Y. Fan, Z. Yufeng, L. Yunsong, and Z. Yongsheng, Research Status of Biodegradable Metals Designed for Oral and Maxillofacial Applications: A Review, Bioact. Mater., 2021, 6, p 4186–4208.

D. Vojtčch, J. Kubásek, J. Šerák, and P. Novák, Mechanical and Corrosion Properties of Newly Developed Biodegradable Zn-Based Alloys for Bone Fixation, Acta Biomater., 2011, 7, p 3515–3522.

H.F. Li, X.H. Xie, Y.F. Zheng, Y. Cong, F.Y. Zhou, K.J. Qiu, X. Wang, S.H. Chen, L. Huang, and L. Tian, Development of Biodegradable Zn-1X Binary Alloys with Nutrient Alloying Elements Mg, Ca and Sr, Sci. Rep., 2015, 5, p 10719–10813.

N.S. Murni, M.S. Dambatta, S.K. Yeap, G.R.A. Froemming, and H. Hermawan, Cytotoxicity Evaluation of Biodegradable Zn-3Mg Alloy Toward Normal Human Osteoblast Cells, Mater. Sci. Eng. C, 2015, 49, p 560–566.

L. Huafang, Y. Hongtao, Z. Yufeng, Z. Feiyu, Q. Kejin, and W. Xiang, Design and Characterizations of Novel Biodegradable tErnary Zn-Based Alloys with IIA Nutrient Alloying Elements Mg, Ca and Sr, Mater. Des., 2015, 83, p 95–102.

J. Kubásek and D. Vojtĕch, Structural and Corrosion Characteristics of Biodegradable Mg-RE(RE=Gd, Y, Nd) Alloys, Trans Nonferrous Met. Soc. China, 2013, 23, p 1215–1225.

M.S. Dambatta, S. Izman, D. Kurniawan, Saeed Farahany, H. Bashir Yahaya, and Hermawan, Influence of Thermal Treatment on Microstructure, Mechanical and Degradation Properties of Zn-3Mg Alloy as Potential Biodegradable Implant Material, Mate. Des., 2015, 85, p 431–437.

X.W. Liu, J.K. Sun, K.J. Qiu, Y.H. Yang, Z.G. Pu, L. Li, and Y.F. Zheng, Effects of Alloying Elements (Ca and Sr)on Microstructure, Mechanical Property and in vitro Corrosion Behavior of Biodegradable Zn-1.5Mg Alloy, J. Alloys Compd., 2016, 664, p 444–452.

Z.W. Yang, H. Liu, K.X. Ren, L.F. Ye, X.R. Zhuo, J. Ju, F. Xue, J. Bai, J.H. Jiang, and Y.C. Xin, A High Strength and Ductility Zn-Cu-Mg alloy Achieved by Bandlike Distribution of Ultra-Fine CuZn5 and Mg2Zn11 Particles, Mater. Sci. Eng. A, 2022, 850, p 143584.

H. Liu, L.F. Ye, K.X. Ren, C. Sun, X.R. Zhuo, K. Yan, J. Ju, J.H. Jiang, F. Xue, and J. Bai, Evolutions of CuZn5 and Mg2Zn11 Phases During ECAP and their Impact on Mechanical Properties of Zn-Cu-Mg Alloys, J. Mater. Res. Technol., 2022, 21, p 5032–5044.

B.K. Prasad, Wear Response of a Zinc-Based Alloy Containing Silicon as Influenced by Material Microstructure and Test Conditions, Mater. Sci. Eng. A, 2004, 367, p 63–73.

D.C.M. Eleani, C.V. Cesar Edilda, R.S. Felipe Dalla, Maurício Cristiane, D.S.A. Carlos, and A.D. Berenice, Study of the Influence of Copper and Magnesium Additions on the Microstructure Formation of Zn-Al Hypoeutectic Alloys, J. Alloys. Compd., 2009, 488, p 89–99.

M. Sharififar and S.A.A.A. Mousavi, Tensile Deformation and Fracture Behavior of CuZn5 Brass Alloy at High Temperature, Mater. Sci. Eng. A, 2014, 594, p 118–124.

Z.B. Tang, J.L. Niu, H. Huang, H. Zhang, J. Pei, J.G. Ou, and G.Y. Yuan, Potential Biodegradable Zn-Cu Binary Alloys Developed for Cardiovascular Implant Applications, J. Mech. Beha. Biomed. Mater., 2017, 72, p 182–191.

Z.B. Tang, H. Huang, J.L. Niu, L. Zhang, H. Zhang, J. Pei, J.Y. Tan, and G.Y. Yuan, Design and Characterizations of Novel Biodegradable Zn-Cu-Mg Alloys for Potential Biodegradable Implants, Mater. Des., 2017, 117, p 84–94.

C.Z. Yao, Z.C. Wang, S.L. Tay, T.P. Zhu, and W. Gao, Effects of Mg on Microstructure and Corrosion Properties of Zn–Mg Alloy, J. Alloys. Compd., 2014, 602, p 101–107.

L.L. Zhu, S. Zaidi, Y. Peng, H. Zhou, B.S. Moonga, A. Blesius, I. Dupin-Roger, M. Zaidi, and L. Sun, Induction of a Program Gene Expression during Osteoblast Differentiation with Strontium Ranelate, Biochem. Biophys. Res. Commun., 2007, 355, p 307–311.

B. Jia, H.T. Yang, Z.C. Zhang, X.H. Qu, X.F. Jia, Q. Wu, Y. Han, Y.F. Zheng, and K. Dai, Biodegradable Zn-Sr Alloy for Bone Regeneration in rat Femoral Condyle Defect Model: In vitro and in vivo Studies, Bioa. Mater., 2021, 6, p 1588–1604.

H.X. Wang, Y. Zhang, C.H. Wu, Q.Y. Lu, L.L. Liu, and Y.J. Xue, Effect of Gd Content on Microstructure and Properties of Zn-1.2Cu-1.2Mg Zinc Alloy, Rare Metal Mater. Eng., 2021, 12, p 4282–4285.

S.H. Cai, T. Lei, N.F. Li, and F.F. Feng, Effects of Zn on Microstructure, Mechanical Properties and Corrosion Behavior of Mg–Zn Alloys, Mater. Sci. Eng. C Mater. Biol. Appl., 2012, 32, p 2570–2577.

D. Vojtech, J. Kubasek, J. Serak, and P. Novak, Mechanical and Corrosion Properties of Newly Developed Biodegradable Zn-Based Alloys for Bone Fixation, Acta Biomater., 2011, 7, p 3515–3522.

J. Kubásek, D. Vojtěch, E. Jablonská, I. Pospíšilová, J. Lipov, and T. Ruml, Structure, Mechanical Characteristics and in vitro Degradation, Cytotoxicity, Genotoxicity and Mutagenicity of Novel Biodegradable Zn-Mg Alloys, Mater. Sci. Eng. C, 2016, 58, p 24–35.

J. Venezuela and M.S. Dargusch, The Influence of Alloying and Fabrication Techniques on the Mechanical Properties, Biodegradability and Biocompatibility of Zinc: A Comprehensive Review, Acta Biomater., 2019, 87, p 11–40.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, H., Zhang, Y., Mao, X. et al. Effect of Sr and Gd on Microstructure and Properties of Zn-2Cu-0.8 Mg Alloy. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08293-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08293-7