Abstract

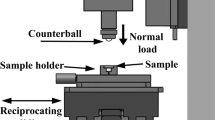

Tribological properties are the significant factors to evaluate the application of polycrystalline cubic boron nitride(PcBN) with hard materials in vacuum conditions. In the current paper, the tribological properties of PcBN and WC-Co cemented carbide (YG8) during the sliding process are carried out under different loads in vacuum by ball-disk friction and wear experiments. The wear tracks of PcBN and wear scars of YG8 were characterized. The results show that the wear mechanisms of PcBN in vacuum are mainly abrasive wear and adhesive wear. Furthermore, furrows are also detected on the surface of YG8 balls due to the plowing of exfoliated cubic boron nitride. As a result, abrasive wear is the failure form of YG8 ball. The average CoF is negatively correlated with the loads. Moreover, the relationship between friction and wear is discussed deeply. The wear rate of YG8 ball is positively correlated with the load. Additionally, the wear rate ratio of PcBN and YG8 indicates that higher loads can promote the wear rate of YG8, but it also leads to the rapid wear of PcBN. The results could provide significant instructions for the regulation and control of the tribological properties of PcBN in the coming outer space exploration activities.

Similar content being viewed by others

References

W. Yu, J. Wang, Y. Wu, Z. Zou, and P. Mo, In Situ Synthesis of Polycrystalline Cubic Boron Nitride with High Mechanical Properties Using Rod-shaped TiB2 Crystals as the Binder, Adv. Appl. Ceram., 2017, 116, p 1–9.

D. Meng, Y. Zhao, W. Yue, Z. Wu, J. Cui, W. Qin, and C. Wang, Thermal Effects on Tribological Behaviors of Polycrystalline Cubic Boron Nitride, Ceram. Int., 2021, 47(1), p 7117–7125.

B. Yaman and H. Mandal, Spark Plasma Sintering of Co-WC Cubic Boron Nitride Composites, Mater. Lett., 2009, 63, p 1041–1043.

U. Umer, High Speed Turning of H-13 Tool Steel Using Ceramics and PCBN, J. Mater. Eng. Perform., 2012, 21, p 1857–1861.

S.N. Monteiro, A.L.D. Skury, M.G. de Azevedo, and G.S. Bobrovnitchii, Cubic Boron Nitride Competing with Diamond as a Superhard Engineering Material– an Overview, J. Mater. Res. Technol., 2013, 2(1), p 68–74.

Z.W. Rao, G.D. Xiao, B. Zhao, Y.J. Zhu, and W.F. Ding, Effect of Wear Behaviour of Single Mono- and Poly-crystalline cBN Grains on the Grinding Performance of Inconel 718, Ceram. Int., 2021, 47, p 17049–17056.

R. Msoubi, D. Axinte, S.L. Soo, C. Nobel, H. Attia, G. Kappmeyer, S. Engin, and W.M. Sim, High Performance Cutting of Advanced Aerospace Alloys and Composite Materials, CIRP Ann. Manuf. Technol., 2015, 64(2), p 557–580.

M.A. Yallese, K. Chaoui, N. Zeghib, L. Boulanouar, and J.F. Rigal, Hard Machining of Hardened Bearing Steel using Cubic Boron Nitride Tool, J. Mater. Process. Technol., 2009, 209, p 1092–1104.

D. Boing, A. Ganea, U. Brohede, E. Stålnacke, and S. Norgren, The Impact of the Retained Austenite in the Case-hardened Steels on the Crater Wear Formation of the PcBN Tools, Wear, 2021, 476, 203691.

B. Zhao, W. Ding, G. Xiao, J. Zhao, and Z. Li, Self-sharpening Property of Porous Metal-bonded Aggregated cBN Wheels during the Grinding of Ti-6Al-4V alloys, Ceram. Int., 2022, 48, p 1715–1722.

B. Sachin and C.M. Rao, Minimum Quantity Lubrication through the Micro-hole Textured PCD and PCBN Inserts in the Machining of the Ti-6Al-4V Alloy, Tribol. Int., 2020, 153, 106619.

Y. Cao, J. Yin, W. Ding, and J. Xu, Alumina Abrasive Wheel Wear in Ultrasonic Vibration-assisted Creep-feed Grinding of Inconel 718 Nickel-based Superalloy, J. Mater. Process. Tech., 2021, 297, 117241.

Q. Miao, W. Ding, J. Xu, L. Cao, H. Wang, Z. Yin, C. Dai, and W. Kuang, Creep Feed Grinding Induced Gradient Microstructures in the Superficial Layer of Turbine Blade Root of Single Crystal Nickel-based Superalloy, Int. J. Extrem. Manuf., 2021, 3, 045102.

B. Zhao, B. Wu, Y. Yue, W. Ding, J. Xu, and G. Guo, Developing a Novel Radial Ultrasonic Vibration-assisted Grinding Device and Evaluating its Performance in Machining PTMCs, Chin. J. Aeronaut., 2023, (in Press).

K.H. Habig, Fundamentals of the Tribological Behaviour of Diamond, Diamond-like Carbon and Cubic Boron Nitride Coatings, Surf. Coat. Tech., 1995, 76–77, p 540–547.

S. Watanabe, S. Miyake, and M. Murakawa, Tribological Behavior of Cubic Boron Nitride Film Sliding Against Diamond, ASME J. Tribol., 1995, 117(4), p 629–633.

Z. Yu, K. Inagawa, and Z. Jin, Tribological properties of c-BN coatings in vacuum at high temperature, Surf. Coat. Tech., 1994, 70(1), p 147–150.

D. Zhao, S. Jiang, D. Tang, and X. Hu, The Application of CBN on the Lunar Rock Drill, Int. Conf. Adv. Eng. Mater. Technol., 2015.

R.B. Soares, A.M.P. de Jesus, R.J.L. Neto, B. Chirita, P.A.R. Rosa, and A. Reis, Comparison Between Cemented Carbide and PCD Tools on Machinability of a High Silicon Aluminum Alloy, J. Mater. Eng. Perform., 2017, 26, p 4638–4657.

F. Yang, Z. Wu, D. Meng, W. Qin, and D. She, Tribological Behaviors of Polycrystalline Cubic Boron Nitride Sliding Against Bearing Steel in Vacuum Condition, Coatings, 2022, 12, p 693.

Y. Li, D. Meng, Z. Wu, D. She, J. Kang, and W. Yue, Contact Stress-induced Wear Mechanism Transitions of PcBN/Al2O3 under Vacuum and Air Conditions, ASME J. Tribol., 2023, 145, p 041704.

J.F. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24, p 981–988.

B Bhatt, TSRC Murthy, A Nagaraj, K Singh, JK Sonber, K Sairam, A Sashanka, GVS Nageswara-Rao, T Srinivasa-Rao, and V Kain, Wear Behaviour of CrB2 + 5 wt.% MoSi2 Composite Against Cemented Tungsten Carbide (WC-Co) under Dry Reciprocative Sliding Condition, J. Aust. Ceram. Soc., 2017, 53, p 611–625.

J. Cui, D. Meng, Z. Wu, W. Qin, D. She, J. Kang, R. Zhang, C. Wang, and W. Yue, Tribological Behaviors of Polycrystalline Cubic Boron Nitride Sliding Against Silicon Nitride in Air and Vacuum Conditions, Ceram. Int., 2022, 48(1), p 363–372.

K.A. Zacny and G.A. Cooper, Friction of Drill Bits under Martian Pressure, J. Geophys. Res.-Planet., 2017, 112, p E03003.

W. Qin, Y. Liu, W. Yue, C. Wang, G. Ma, and H. Wang, Infuence of Frictional Interface State on Tribological Performance of Sintered Polycrystalline Diamond Sliding Against Diferent Mating Materials, Tribol. Lett., 2019, 67, p 87.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (51875537, 41902319), Beijing Natural Science Foundation (3214052), the Fundamental Research Funds for the Central Universities (2652019109), and the Pre-Research Program in National 14th 5-Year Plan (61409230614).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, H., Meng, D., Wu, Z. et al. Tribological Behavior of Polycrystalline Cubic Boron Nitride Sliding against WC-Co Cemented Carbide in Vacuum Conditions. J. of Materi Eng and Perform 33, 1975–1984 (2024). https://doi.org/10.1007/s11665-023-08119-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08119-6