Abstract

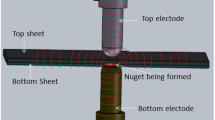

The process monitoring (PM) of refill friction stir spot welding (Refill FSSW) can play a substantial role in detecting various issues, especially defects in the spot being formed and the tool state degradation, which allows in time intervention to improve the welding process. Since Refill FSSW is somewhat an emergent technology, PM has received scarce attention. In this paper, the performance of PM using acoustic emission (AE) technique is studied for two purposes: detecting defects in weld while being formed and predicting the tool state. To do so, the common defects that can occur during the process were first intentionally created and monitored using AE. The corresponding collected data have served then as an input for two defect detection models. The first one is based on novelty detection and has shown an average classification performance. The second, which shows higher performance, uses multi-class classification algorithms. Concerning the tool state, a novel state index was developed to predict when the process must be stopped in order to clean the tool and avoid hence related weld defects and tool fracture.

Similar content being viewed by others

References

A.M. Nasiri, Z. Shen, J.S.C. Hou, and A.P. Gerlich, Failure Analysis of Tool Used in Refill Friction Stir Spot Welding of Al 2099 Alloy, Eng. Fail. Anal., 2018, 84, p 2533.

Z. Shen, Y. Chen, J.S.C. Hou, X. Yang, A.P. Gerlich, Influence of processing parameters on microstructure and mechanical performance of refill friction stir spot welded 7075–T6 aluminium alloy. Sci. Technol. Weld. Join., 2015, 20(1), p 48–57.

C. Schilling and J. dos Santos, U.S. Patent No. 6,722,556B2 (2002). Method and and device for joining at least two adjoining work pieces by friction welding. https://patents.google.com/patent/US6722556B2/en

U. Suhuddin, R. Mesquita, and J.F. Santos, Friction Spot Welding of Similar Aluminum Alloys AA6082-T6 for Application in Automotive Industry. Int. Automot. Congr.-IABC. (2016)

E. Boldsaikhan, S. Fukada, M. Fujimoto, K. Kamimuki, and H. Okada, Refill Friction Stir Spot Welding of Surface-Treated Aerospace Aluminum Alloys with Faying-Surface Sealant, J. Manuf. Process., 2019, 42, p 113–120.

I. Kwee, W. De Waele, and K. Faes, Weldability of High-Strength Aluminium Alloy EN AW-7475-T761 Sheets for Aerospace Applications, Using Refill Friction Stir Spot Welding, Weld. World, 2019, 63(4), p 1001–1011.

J.Y. Cao, M. Wang, L. Kong, H.X. Zhao, and P. Chai, Microstructure, Texture and Mechanical Properties During Refill Friction Stir Spot Welding of 6061–T6 Alloy, Mater. Charact., 2017, 128, p 54–62.

B.H. Silva, G. Zepon, C. Bolfarini, and J.F. dos Santos, Refill Friction Stir Spot Welding of AA6082-T6 Alloy: Hook Defect Formation and Its Influence on the Mechanical Properties and Fracture Behavior, Mater. Sci. Eng. A, 2020, 773, p 138724.

C.C. de Castro, A.H. Plaine, G.P. Dias, N.G. de Alcântara, and J.F. dos Santos, Investigation of Geometrical Features on Mechanical Properties of AA2198 Refill Friction Stir Spot Welds, J. Manuf. Process., 2018, 36, p 330–339.

U.F.H. Suhuddin, V. Fischer, A. Kostka, and J.F. Dos Santos, Microstructure Evolution in Refill Friction Stir Spot Weld of A Dissimilar Al-Mg Alloy to Zn-Coated Steel, Sci. Technol. Weld. Join., 2017, 22(8), p 658–665.

Y.Q. Zhao, H.J. Liu, S.X. Chen, Z. Lin, and J.C. Hou, Effects of Sleeve Plunge Depth on Microstructures and Mechanical Properties of Friction Spot Welded Alclad 7B04-T74 Aluminum Alloy, Mater. Des., 2014, 1980–2015(62), p 40–46.

A.C. Ferreira, L.C. Campanelli, U.F.H. Suhuddin, N.G. de Alcântara, and J.F. dos Santos, Investigation of Internal Defects and Premature Fracture of Dissimilar Refill Friction Stir Spot Welds of AA5754 and AA6061, Int. J. Adv. Manuf. Technol., 2020, 106(7), p 3523–3531.

A. Kubit and T. Trzepiecinski, A Fully Coupled Thermo-Mechanical Numerical Modelling of the Refill Friction Stir Spot Welding Process in Alclad 7075–T6 Aluminium Alloy Sheets, Arch. Civ. Mech. Eng., 2020, 20(4), p 1–14.

R.C. Brzostek, U. Suhuddin, and J.F. Dos Santos, Fatigue Assessment of Refill Friction Stir Spot Weld in AA 2024–T3 Similar Joints, Fatigue Fract. Eng. Mater. Struct., 2018, 41(5), p 1208–1223.

Z. Xu, Z. Li, S. Ji, and L. Zhang, Refill Friction Stir Spot Welding of 5083-O Aluminum Alloy, J. Mater. Sci. Technol., 2018, 34(5), p 878–885.

C. Schmal, G. Meschut, and N. Buhl, Joining of High Strength Aluminum Alloys by Refill Friction Stir Spot Welding (III-1854-18), Weld. World, 2019, 63(2), p 541–550.

SIST EN 1330–9: 2017-Non-destructive testing - Terminology - Part 9: Terms used in acoustic emission testing. https://standards.iteh.ai/catalog/standards/cen/a4599dc9-83ab-41f5-9afa-07ac2ea9f8db/en-1330-9-2017

ASTM E751/E751M-17: Standard practice for acoustic emission monitoring during resistance spot-welding. https://www.boutique.afnor.org/fr-fr/norme/astm-e751-e751m17//am97528/275744

K. Dudzik, The Possibility of Application Acoustic Emission Method to Optimize Determination of Finish Lathing Parameters, J. Kones, 2015, 22(3), p 33–39.

C.N. Suresha, B.M. Rajaprakash, and S. Upadhya, Applicability of Acoustic Emission in the Analysis of Friction Stir Welded Joints, Int. J. Recent Trends Eng., 2009, 1(5), p 86.

S.K. Oh, A. Hasui, T. Kunio, and KWang, K., Effects of Initial Energy on Acoustic Emission Relating to Weld Strength in Friction Welding, Trans. JWS, 1982, 13(2), p 24–26.

C. Chen, R. Kovacevic, and D. Jandgric, Wavelet Transform Analysis of Acoustic Emission in Monitoring Friction Stir Welding of 6061 Aluminum, Int. J. Mach. Tools Manuf, 2003, 43(13), p 1383–1390.

A. Levikhina, Nondestructive Online Testing Method for Friction Stir Welding using acoustic emission. in AIP Conference Proceedings (Vol 1909, No. 1, p. 020116). AIP Publishing LLC 2017

D. Ambrosio, G. Dessein, V. Wagner, M. Yahiaoui, J.Y. Paris, M. Fazzini, and O. Cahuc, On the Potential Applications of Acoustic Emission in Friction Stir Welding, J. Manuf. Process., 2022, 75, p 461–475.

W.D. Jolly, Use of Acoustic Emission as a Weld Quality Monitor (No. BNWL-SA-2727; CONF-690962–1). Battelle-Northwest, Richland, Wash. Pacific Northwest Lab. (1969)

S. Charunetratsamee, B. Poopat, and C. Jirarungsatean, Feasibility Study of Acoustic Emission Monitoring of Hot Cracking in GTAW Weld. In Key Engineering Materials (Vol. 545, pp. 236–240). Trans Tech Publications Ltd. (2013)

S. Yaacoubi, F. Dahmene, M. El Mountassir, and A.E. Bouzenad, A Novel AE Algorithm-Based Approach for the Detection of Cracks in Spot Welding in View of Online Monitoring: Case Study, Int. J. Adv. Manuf. Technol., 2021, 117(5), p 1807–1824.

F. Dahmene, S. Yaacoubi, M.E. Mountassir, A.E. Bouzenad, P. Rabaey, M. Masmoudi, and A. Taram, On the Nondestructive Testing and Monitoring of Cracks in Resistance Spot Welds: Recent Gained Experience, Weld. World, 2022, 66(4), p 629–641.

W.M. Zeng, H.L. Wu, and J. Zhang, Effect of Tool Wear on Microstructure, Mechanical Properties and Acoustic Emission of Friction Stir Welded 6061 Al Alloy, Acta Metallurgica Sinica (English Lett.), 2006, 19(1), p 9–19.

F. Al-Badour, A. Mahgoub, A. Bazoune, A. Shuaib, and N. Merah, On-Line Condition Monitoring of Friction Stir Spot Welding Tool Using Vibration Measurements. in Pressure Vessels and Piping Conference (vol. 57991, p. V06AT06A023). American Society of Mechanical Engineers. (2017)

L. Zuo, D. Zuo, Y. Zhu, and H. Wang, Acoustic Emission Analysis for Tool Wear State During Friction Stir Joining of SiCp/Al Composite, Int. J. Adv. Manuf. Technol., 2018, 99(5), p 1361–1368.

K. Balachandar and R. Jegadeeshwaran, Friction Stir Welding Tool Condition Monitoring Using Vibration Signals and Random Forest Algorithm–A Machine Learning Approach, Mater. Today Proc., 2021, 46, p 1174–1180.

T. Montag, J.P. Wulfsberg, H. Hameister, and R. Marschner, Influence of Tool Wear on Quality Criteria for Refill Friction Stir Spot Welding (RFSSW) process, Procedia Cirp, 2014, 24, p 108–113.

N. Morizet, N. Godin, J. Tang, E. Maillet, M. Fregonese, and B. Normand, Classification of Acoustic Emission Signals Using Wavelets and RANDOM Forests: Application to Localized Corrosion, Mech. Syst. Signal Process., 2016, 70, p 1026–1037.

T.J. Saravanan, N. Gopalakrishnan, and N.P. Rao, Damage Detection in Structural Element Through Propagating Waves Using Radially Weighted and Factored RMS, Measurement, 2015, 73, p 520–538.

D. D’Angela and M. Ercolino, Acoustic Emission Entropy: An Innovative Approach for Structural Health Monitoring of Fracture-Critical Metallic Components Subjected to Fatigue Loading, Fatigue Fract. Eng. Mater. Struct., 2021, 44(4), p 1041–1058.

S. Chen, C. Yang, G. Wang, and W. Liu, Similarity Assessment of Acoustic Emission Signals and Its Application in Source Localization, Ultrasonics, 2017, 75, p 36–45.

P. Senin, Dynamic Time Warping Algorithm Review Information and Computer Science Department University of Hawaii, Technical Report, Manoa Honolulu, 2008.

H.W. Lilliefors, On the Kolmogorov-Smirnov Test for Normality with Mean and Variance Unknown, J. Am. Stat. Assoc., 1967, 62(318), p 399–402.

M. Hofmann, Support Vector Machines-Kernels and the Kernel Trick, Notes, 2006, 26(3), p 1–16.

Platt, J. (1998). Sequential Minimal Optimization: A Fast Algorithm for Training Support Vector Machines.

S.I. Amari and S. Wu, Improving Support Vector Machine Classifiers by Modifying Kernel Functions, Neural Netw., 1999, 12(6), p 783–789.

E. Fix and J.L. Hodges, Discriminatory Analysis. Nonparametric Discrimination: Consistency Properties, Int. Stat. Rev., 1989, 57(3), p 238–247.

D.W. Aha Ed., Lazy Learning. Springer, Berlin, 2013

L. Breiman, J.H. Friedman, R.A. Olshen, and C.J. Stone, Classification and Regression Trees, Routledge, Oxford, 2017.

T. Hastie, R. Tibshirani, J.H. Friedman, and J.H. Friedman, The Elements of Statistical Learning: Data Mining, Inference, and Prediction, Springer, New York, 2009.

R.A. Fisher, The Use of Multiple Measurements in Taxonomic Problems, Ann. Eugen., 1936, 7, p 179–188.

C.R. Rao, The Utilization of Multiple Measurements in Problems of Biological Classification, J. Royal Stat. Soc. Ser. B (Methodol.), 1948, 10(2), p 159–203.

B.L. Welch, Note on Discriminant Functions, Biometrika, 1939, 31, p 218–220.

T.T. Wong, Performance Evaluation of Classification Algorithms by k-Fold and Leave-One-Out Cross Validation, Pattern Recogn., 2015, 48(9), p 2839–2846.

Giesteira, F. A. G. (2018). Refill Friction Stir Spot Welding of Casting AM50A Mg Alloy to Zn Coated DP600 Steel Dissimilar Joints.

A. Marec, J.H. Thomas, and R. El Guerjouma, Damage Characterization of Polymer-Based Composite Materials: Multivariable Analysis and Wavelet Transform for Clustering Acoustic Emission Data, Mech. Syst. Signal Process., 2008, 22(6), p 1441–1464.

A.H. Najmi and J. Sadowsky, The Continuous Wavelet Transform and Variable Resolution Time-Frequency Analysis, J. Hopkins APL Tech. Dig., 1997, 18(1), p 134–140.

H. Suzuki, T. Kinjo, Y. Hayashi, M. Takemoto, K. Ono, and Y. Hayashi, Wavelet Transform of Acoustic Emission Signals, J. Acoust. Emiss., 1996, 14, p 69–84.

M. El Mountassir, S. Yaacoubi, G. Mourot, and D. Maquin, An Adaptive PCA-Based Method for More Reliable Ultrasonic Guided Waves SHM: Data-Driven Modeling and Experimental Validation in High Attenuating Medium, Struct. Control. Health Monit., 2021, 28(1), p e2634.

Acknowledgments

This work has been conducted within the scope of the European Project DAHLIAS (Development and Application of Hybrid Joining in Lightweight Integral Aircraft Structures). This project is funded by European Union’s HORIZON 2020 framework program, Clean Sky 2 Joint Undertaking, and AIRFRAME ITD under grant agreement No 821081.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dahmene, F., Yaacoubi, S., El Mountassir, M. et al. An Original Machine Learning-Based Approach for the Online Monitoring of Refill Friction Stir Spot Welding: Weld Diagnostic and Tool State Prognostic. J. of Materi Eng and Perform 33, 1931–1947 (2024). https://doi.org/10.1007/s11665-023-08102-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08102-1