Abstract

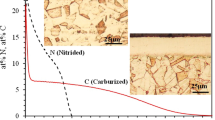

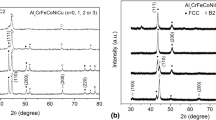

This study explored the effect of pre-corrosion damage on the tribology behavior of the austenitized and the different tempered conditions of 13 wt.% Cr martensitic stainless steel under dry sliding conditions using a “ball on plate” configuration. Corrosion immersion experiments were performed in 5 wt.% HNO3 solution at room temperature for 30 min. The austenitized and the tempered at 300 °C (T300) specimens displayed the attack along the prior austenitic grain boundaries, whereas the specimens tempered at 550 (T550) and 700 °C (T700) showed intergranular plus interlath corrosion and uniform corrosion, respectively. Subjecting this corrosion-damaged specimens to dry sliding revealed non-monotonic friction and wear behavior with tempering temperature. The microstructure and the type of corrosion attack together determined the overall wear performance of the tempered conditions. The specific wear rate (k) decreased in the order kT700 > kT550 > kT300 ~ kaustenitized. The k value of the austenitized and the T300 specimens (~ 32 − 35 × 10−6 mm3/Nm) is observed to be 12 and 15 times lower than the k value of T550 (~ 408 × 10−6 mm3/Nm) and T700 (~ 495 × 10−6 mm3/Nm) specimens, respectively. The reason for the lower k value is due to the continuous, thick (~ 4 μm thickness) Cr-rich tribo-film that formed on the wear track and acted as solid lubricant. The T550 and T700 specimens had a discontinuous Fe-rich tribo-film on the wear tracks; therefore, rubbing in the presence of harder and loose Fe-rich oxides particles led to severe adhesion plus galling in T550 and smearing plus plastic deformation in T700 specimens. It was also found that the wear rate and surface damage are reduced for pre-corroded austenitized and T300 specimens compared to the respective unattacked pristine specimens; however, the opposite effect was observed in T550 and T700 specimens.

Similar content being viewed by others

References

S.J. Zinkle and G.S. Was, Materials Challenges in nuCLEAR energy, Acta Mater., 2013, 61, p 735–758.

T. Allen, J. Busby, M. Meyer, and D. Petti, Materials Challenges for Nuclear Systems, Mater. Today, 2010, 13(12), p 14–23.

M. Narayana Rao, Materials Development for Indian Nuclear Power Programme: An Industry Perspective, Energy Procedia, 2011, 7, p 199–204.

W.M. Garrison Jr., Stainless steels: martensitic, encyclopedia of Materials: Science and Technology, second, K.H.J. Buschow Ed., Elsevier, Oxford, UK, 2001, p 8804–8810

S.K. Bonagani, V. Bathula, and V. Kain, Influence of Tempering Treatment on Microstructure and Pitting Corrosion of 13 wt.% Cr Martensitic Stainless Steel, Corros. Sci., 2018, 131, p 340–354.

I. Taji, M.H. Moayed, and M. Mirjalili, Correlation Between Sensitization and Pitting Corrosion of AISI 403 Martensitic Stainless Steel, Corros. Sci., 2015, 92, p 301–308.

B. Sunil Kumar, V. Kain and B. Vishwanadh, Effect of Tempering Treatments on Microstructure and Intergranular Corrosion of 13 wt.% Cr Martensitic Stainless Steel, Corrosion, 2016, 73(4), p 362–378.

S.K. Bonagani, V. Kain, V. Bathula, R.H. Banerjee, and S. Tenneti, Electrochemical Behavior and Passive Property of 13Cr Martensitic Stainless Steel in Nitric Acid Solution, J. Mater. Eng. Perform., 2020, 29(1), p 215–229.

N. Khare, S.K. Bonagani, P.K. Limaye, and V. Kain, Tribological Study on Tempered 13Cr Martensitic Stainless Steel Susceptible to Interlath/Intergranular Corrosion Under Nitric Acid Sliding Conditions, Mater. Chem. Phys., 2022, 285, p 126097.

S. Jacobson and S. Hogmark, Tribofilms- on the crucial importance of tribologically induced surface modifications. In Book: Recent Developments in Wear Prevention, Friction and Lubrication, Research Signpost (2010), p. 197–225

X. Cheng, Z. Jiang, B. Kosasih, H. Wu, S. Luo, and L. Jiang, Influence of Cr-Rich Oxide Scale on Sliding Wear Mechanism of Ferritic Stainless Steel at High Temperature, Tribol. Lett., 2016, 63(2), p 1–13.

M.M. De Oliveira Junior, H.L. Costa, W.M. Silva Junior, and J.D.B. De Mello, Effect of Iron Oxide Debris on the Reciprocating Sliding Wear of Tool Steels, Wear, 2019, 426–427, p 1065–1075.

Y.G. Cao, C.H. Yin, Y.L. Liang, and S.H. Tang, Lowering the Coefficient of Martensite Steel by Forming a Self-Lubricating Layer in Dry Sliding Wear, Mater. Res. Express, 2019, 6, p 055024.

Y. Chen, Y. Tang, H. Zhang, and L. Fu, Effect of Chromium on Oxidation in Wear of Surface Nanocrystalline Martensite Steel, Tribol. Lett., 2016, 7, p 61.

P.J. Blau, Mechanisms for Transitional Friction and Wear Behavior of Sliding Metals, Wear, 1981, 72, p 55.

K. Chu, F. Ren, W. Zhu, C. Zhao, P. Bellon, and R.S. Averback, Sliding Wear Induced Subsurface Microstructural Evolution in Nanocrystalline Nb-Ag Binary Alloys and Its Impact on Tribological Performance, Wear, 2017, 392–393, p 69–76.

S. Jacobson and S. Hogmark, Surface Modifications in Tribological Contact, Wear, 2009, 266, p 370–378.

S. Masuko, T. Iijima, A. Terawaki, S. Suzuki, T. Aoki, S. Nogi, and S. Obara, Effect of Surface Oxide Layer of Steel on the Tribological Characteristics of Load-bearing Additives for Multiply-Alkylated Cyclopentane Oil Under High Vacuum, Tribol. Lett., 2013, 51(1), p 115–125.

K.L. Dahm, E. Torskaya, I. Goryacheva, and P.A. Dearnley, Tribological effects on subsurface interfaces, Proc. Inst. Mech. Eng. P. I. Mech. Eng. J-J Eng., 2007, 221, p 345.

L.G. Korshunov and N.L. Chernenko, Effect of Friction-Induced Deformation on the Structure, Microhardness, and Wear Resistance of Austenitic Chromium—Nickel Stainless Steel Subjected to Subsequent Oxidation, Phys. Met. Metallogr., 2016, 117, p 307–313.

S.Q. Wang, M.X. Wei, F. Wang, X.H. Cui, and C. Dong, Transition of Mild Wear to Severe Wear in Oxidative Wear of H21 Steel, Tribol. Lett., 2008, 32(2), p 67–72.

M.X. Wei, S.Q. Wang, L. Wang, and X.H. Cui, Wear and Friction Characteristics of a Selected Stainless Steel, Tribol. Trans., 2011, 54(6), p 840–848.

A. Dalmau, C. Richard, and A.I. Muñoz, Degradation Mechanisms in Martensitic Stainless Steels: Wear, Corrosion and Tribocorrosion Appraisal, Tribol. Int., 2018, 121, p 167–179.

A. Gassner, H. Palkowski, C. Müller, J. Wilde, and H. Mozaffari-Jovein, Effect of Microstructural Evolution During Dry Sliding on the Corrosion Behaviour of Martensitic Stainless Steel, IJMR, 2022, 113(9), p 820–832.

Z. Dai, S. Jiang, B. Wu, L. Ning, S. Li, and D. Duan, Synergism Between Wear and Corrosion of Cr26Mo1 Ferrite Stainless Steels in 0.5 mol/L of Sulfuric Acid, Tribol. Int. Part, 2023, A178, p 108007.

R. Bateni, J.A. Szpunar, X. Wang, and D.Y. Li, Wear and Corrosion Wear of Medium Carbon Steel and 304 Stainless Steel, Wear, 2006, 260(1–2), p 116–122.

A.N. Isfahany, H. Saghafian, and G. Borhani, The Effect of Heat Treatment on Mechanical Properties and Corrosion Behaviour of AISI420 Martensitic Stainless Steel, J. Alloy Compd., 2011, 509, p 3931–3936.

K. Chandra, V. Kain, N. Srinivasan, I. Samajdar, and A.K. Balasubrahmanian, Temper Embrittlement and Corrosion Behaviour of Martensitic Stainless Steel 420, Century Stainl. Steels, 2013, 794, p 757–765.

N. Khare, S.K. Bonagani, P.K. Limaye, and V. Kain, Effect of Tempering on Tribological Properties of 13Cr Martensitic Stainless Steel and Alumina Material Pair in Dry Sliding, Tribol. Trans., 2021, 64, p 693–707.

J.Y. Park and Y.S. Park, The Effects of Heat-Treatment Parameters on Corrosion Resistance and Phase Transformations of 14Cr–3Mo Martensitic Stainless Steel, Mater. Sci. Eng. A, 2007, 449–451, p 1131–1134.

B. Qin, Z.Y. Wang, and Q.S. Sun, Effect of Tempering Temperature on Properties of 00 Cr 16 Ni 5Mo Stainless Steel, Mater. Charact., 2008, 59, p 1096–1100.

S.K. Bonagani, V. Kain, N.N. Kumar, and H. Donthula, Effect of Austenitization-Cooling on Microstructure and Localized Corrosion Behavior of 13Cr Martensitic Stainless Steel, J. Mater. Eng. Perform., 2021, 30, p 2291–2299.

A. Erdemir, M. Halter, and G.R. Fenske, Preparation of Ultralow-Friction Surface Films on Vanadium Diboride, Wear, 1997, 205(1), p 236–239.

I.M. Hutchings, Tribology: Friction and Wear of Engineering Materials, CRC Press, London, 1992.

J. Williams, Engineering Tribology, Cambridge University Press, Cambridge, UK, 1994.

W.A. Glaeser, in ASM Handbook: Friction, Lubrication, and Wear Technology ed by P.J. Blau (ASM Int., 1992), p. 812–815

G.W. Stachowiak and A.W. Batchelor Eds., Engineering Tribology, Fourth. Butterworth-Heinemann, Boston, 2014, p 293–370

R. Sahli, G. Pallares, C. Ducottet, B. Ali, S. Al Akhrass, M. Guibert, and J. Scheibert, Evolution of Real Contact Area Under Shear and the Value of Static Friction of Soft Materials, Proc. Natl. Acad. Sci., 2018, 115(3), p 471–476.

A.C. Bozzi and J.D.B. de Mello, Wear Resistance and Wear Mechanisms of WC Thermal Sprayed Coatings in Three-Body Abrasion, Wear, 1999, 233–235, p 575–587.

C.C. Viafara and A. Sinatora, Influence of Hardness of the Harder Body on Wear Regime Transition in a Sliding Pair of Steels, Wear, 2009, 267, p 425–432.

T. Akagaki and D.A. Rigney, Sliding Friction and Wear of Metals in Vacuum, Wear, 1991, 149, p 353–374.

T.E. Fischer, Z. Zhu, H. Kim, and D.S. Shin, Genesis and Role of Wear Debris in Sliding Wear of Ceramics, Wear, 2000, 245, p 53–60.

M. Cocks, Wear Debris in the Contact Between Sliding Metals, J. Appl. Phys., 1958, 29, p 1609–1610.

M. Ulutan, M. Mustafa Yildirim, S. Buytoz, and O.C. Elik, Microstructure and Wear Behavior of TIG Surface-Alloyed AISI 4140 Steel, Tribol. Trans., 2011, 54, p 67–79.

Y. Wang and T. Lei, Wear Behavior of Steel 1080 with Different Microstructures During Dry Sliding, Wear, 1997, 36(2), p 213–217.

J.F. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24, p 981–988.

R.A. García-León, J. Martínez-Trinidad, R. Zepeda-Bautista, I. Campos-Silva, A. Guevara-Morales, J. Martínez-Londoño, and J. Barbosa-Saldaña, Dry Sliding Wear Test on Borided AISI 316L Stainless Steel Under Ball-on-Flat Configuration: A Statistical Analysis, Tribol. Inter., 2021, 157, p 106885.

T.F.J. Quinn, Review of Oxidational Wear: Part I: The Origins of Oxidational Wear, Tribol. Inter., 1983, 16(5), p 257–271.

W. Dai, B. Kheireddin, H. Gao, and H. Liang, Roles of Nanoparticles in Oil Lubrication, Tribol. Int., 2016, 102, p 88–98.

W. Xia, J. Zhao, H. Wu, S. Jiao, and Z. Jiang, Effects of Oil-in-Water Based Nano Lubricant Containing TiO2 Nanoparticles on the Tribological Behaviour of Oxidised High-Speedsteel, Tribol. Int., 2017, 110, p 77–85.

S. Ningshen, U.K. Mudali, S. Ramya and B. Raj, Corrosion Behaviour of AISI type 304L Stainless Steel in Nitric Acid Media Containing Oxidizing Species, Corros. Sci., 2011, 53(1), p 64–70.

K. Kato and G.E. Totten Eds., Polishing Wear, Friction, Lubrication, and Wear Technology, Vol 18 ASM International, Almere, 2017

R.A. García-León, J. Martínez-Trinidad, I. Campos-Silva, U. Figueroa-López and A. Guevara-Morales, Development of Tribological Maps on Borided AISI 316L Stainless Steel Under Ball-on-Flat Wet Sliding Conditions, Tribol. Int., 2021, 163, p 1–14.

A. Socoliuc, E. Gnecco, R. Bennewitz and E. Meyer, Ripple Formation Induced Inlocalized Abrasion, Phys. Rev. B., 2003, 68, p 1154161–1154164.

A.E. Filippov, V.L. Popov and M. Urbakh, Mechanism of wear and ripple formation induced by mechanical action of an atomic force microscope tip, Phys. Rev. Lett., 2011, 106, p 025502-1–025502-4.

V. Podgursky, T. Hantschel, A. Bogatov, E. Kimmari, M. Antonov, M. Viljus, V. Mikli, M. Tsigkourakos, W. Vandervorst, J.G. Buijnsters, A.T. Raadik, and P. Kulu, Rippling on Wear Scar Surfaces of Nanocrystalline Diamond Films After Reciprocatingsliding Against Ceramic Balls, Tribol. Lett., 2014, 55(3), p 493–501.

A. Ravikiran and B.N.P. Bai, Influence of Speed on the Tribochemical Reaction Products and the Associated Transitions for the Dry Sliding of Silicon Nitride Against Steel, J. Am. Ceram. Soc., 1995, 78(11), p 3025–3032.

C. Trevisiol, A. Jourani and S. Bouvier, Effect of Microstructures with the Same Chemical Composition and Similar Hardness Levels on Tribological Behavior of Low Alloy Steel, Tribol. Int., 2018, 127, p 389–403.

F.H. Stott and G.C. Wood, Influence of Oxides on Friction and Wear of Alloys, Tribol. Int., 1978, 11(4), p 211–218.

T. Jõgiaas, A. Tarre, H. Mändar, J. Kozlova and A. Tamm, Nanoindentation of Chromium Oxide Possessing Superior Hardness among Atomic-Layer-Deposited Oxides, Nanomaterials, 2022, 12, p 82.

M.M. Taheri, Q. Yang, Y. Li, and J.C. Gomez, The Effect of Deposition Parameters on the Structure and Mechanical Properties of Chromium Oxide Coatings Deposited by Reactive Magnetron Sputtering, Coatings, 2018, 8, p 111.

T. Amano, M. Okazaki, Y. Takezawa, A. Shiino, M. Takeda, T. Onishi, K. Seto, A. Ohkubo, and T. Shishido, Hardness of Oxide Scales on Fe-Si Alloys at Room and High-Temperatures, Mater. Sci. Forum, 2006, 522–523, p 469–476.

A. Wirth, D. Eggleston, and R. Whitaker, A fundamental tribochemical study of the third body layer formed during automotive friction braking, Wear, 1994, 179(1), p 75–81.

K.H. Zum Gahr, Microstructure and Wear of Materials, Elsevier, New York, USA, 1987.

K. Kato and K. Adachi, Wear mechanisms, Modern Tribology. B. Bhushan Ed., CRC Press, London, 2000

Acknowledgments

The authors are grateful to Dr. Madhumita Goswami and Mr. Anurup Das, Glass and Advanced Materials Division, Bhabha Atomic Research Centre, Mumbai for their help in performing Raman spectroscopy.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Khare, N., Bonagani, S.K., Limaye, P.K. et al. Effect of Pre-corrosion Damage on Dry Sliding Wear Behavior of Differently Heat-Treated Martensitic Stainless Steel. J. of Materi Eng and Perform 33, 618–633 (2024). https://doi.org/10.1007/s11665-023-08016-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08016-y