Abstract

Tooth bending failure, one of the gear’s most dangerous failure modes, is caused by alternating bending stress at the tooth root. The fatigue process is divided into crack initiation and crack propagation periods. In this paper, single tooth bending fatigue tests are conducted under a stress ratio of 0.05. Crack initiation life is predicted by the strain-life method. Material gradients and residual stresses are taken into account in the above process. The crack propagation life is predicted by linear elastic fracture mechanics. The Paris equation is used to simulate the fatigue crack growth. Finally, the total bending fatigue life can be estimated. Predicted fatigue life and failure locations show good agreement with the experimental results.

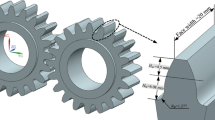

Graphical Abstract

Similar content being viewed by others

Data Availability

The datasets used during the current study are available from the corresponding author on reasonable request.

References

X. Cui, N. Sun, J. Guo, J. Ma, and P. Ming, Green Multi-biomimetic Spontaneous Oil-Transport Microstructure and Its Effects on Energy Consumption in Sustainable Intermittent Cutting, J. Clean. Prod., 2022, 367, p 133035. https://doi.org/10.1016/j.jclepro.2022.133035

X. Cui, S. Duan, J. Guo, and P. Ming, Bionic Multifunctional Surface Microstructure for Efficient Improvement of Tool Performance in Green Interrupted Hard Cutting, J. Mater. Process. Technol., 2022, 305, p 117587. https://doi.org/10.1016/j.jmatprotec.2022.117587

X. Cui, Y. Guo, J. Guo, and P. Ming, Bio-inspired Design of Cleaner Interrupted Turning and Its Effects on Specific Cutting Energy and Harmful Gas Emission, J. Clean. Prod., 2020, 271, p 122354. https://doi.org/10.1016/j.jclepro.2020.122354

W. Feng, Z. Feng, and L. Mao, Failure Analysis of a Secondary Driving Helical Gear in Transmission of Electric Vehicle, Eng. Fail. Anal., 2020, 117, p 104934. https://doi.org/10.1016/j.engfailanal.2020.104934

T.J. Lisle, B.A. Shaw, and R.C. Frazer, External Spur Gear Root Bending Stress: A Comparison of ISO 6336:2006, AGMA 2101-D04, ANSYS Finite Element Analysis and Strain Gauge Techniques, Mech. Mach. Theory, 2017, 111, p 1–9. https://doi.org/10.1016/j.mechmachtheory.2017.01.006

C. Dengo, G. Meneghetti, and M. Dabalà, Experimental Analysis of Bending Fatigue Strength of Plain and Notched Case-Hardened Gear Steels, Int. J. Fatigue, 2015, 80, p 145–161.

G. Meneghetti, C. Dengo, and F. Lo Conte, Bending Fatigue Design of Case-Hardened Gears Based on Test Specimens, Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci., 2018, 232(11), p 1953–1969.

J. Kramberger, M. Šraml, I. Potrč, and J. Flašker, Numerical Calculation of Bending Fatigue Life of Thin-Rim Spur Gears, Eng. Fract. Mech., 2004, 71(4–6), p 647–656.

K. Vučković, I. Galić, Ž Božić, and S. Glodež, Effect of Friction in a Single-Tooth Fatigue Test, Int. J. Fatigue, 2018, 114, p 148–158.

H. Deng, Y. Guo, H. Liu, Q. Liu, Y. Guo, and H. Yu, Bending Fatigue Life Prediction Model of Carburized Gear Based on Microcosmic Fatigue Failure Mechanism, J. Mater. Eng. Perform., 2021 https://doi.org/10.1007/s11665-021-06236-8

V. Savaria, F. Bridier, and P. Bocher, Predicting the Effects of Material Properties Gradient and Residual Stresses on the Bending Fatigue Strength of Induction Hardened Aeronautical Gears, Int. J. Fatigue, 2016, 85, p 70–84. https://doi.org/10.1016/j.ijfatigue.2015.12.004

D.G. Lewicki and R. Ballarini, Effect of Rim Thickness on Gear Crack Propagation Path, J. Mech. Des. Trans. ASME, 1997, 119(1), p 88–95.

Y. Wei and Y. Jiang, Fatigue Fracture Analysis of Gear Teeth Using XFEM, Trans. Nonferrous Met. Soc. China Engl. Ed., 2019, 29(10), p 2099–2108. https://doi.org/10.1016/S1003-6326(19)65116-2

M.S. Raghav, A. Singh, and S. Patel, Fault Analysis of Spur Gear Using XFEM, Eng. Fail. Anal., 2022, 134, p 106060. https://doi.org/10.1016/j.engfailanal.2022.106060

X. Zhang, L. Li, X. Qi, J. Zheng, X. Zhang, B. Chen, J. Feng and S. Duan, Experimental and Numerical Investigation of Fatigue Crack Growth in the Cracked Gear Tooth, Fatigue Fract. Eng. Mater. Struct., 2017, 40(7), p 1037–1047.

R. Thirumurugan and N. Gnanasekar, Influence of Finite Element Model, Load-Sharing and Load Distribution on Crack Propagation Path in Spur Gear Drive, Eng. Fail. Anal., 2020, 110, p 104383. https://doi.org/10.1016/j.engfailanal.2020.104383

A.M. Alshoaibi, Fatigue Crack Growth Analysis under Constant Amplitude Loading Using Finite Element Method, Materials (Basel), 2022, 15(8), p 2937.

I. Čular, K. Vučković, S. Glodež and Z. Tonković, Computational Model for Bending Fatigue Prediction of Surface Hardened Spur Gears Based on the Multilayer Method, Int. J. Fatigue, 2022, 161, p 106892.

Y. Dong, Y. Garbatov, and C. Guedes Soares, Fatigue Crack Initiation Assessment of Welded Joints Accounting for Residual Stress, Fatigue Fract. Eng. Mater. Struct., 2018, 41(8), p 1823–1837.

F. Yin and A. Fatemi, Monotonic and Cyclic Deformations of Case-Hardened Steels Including Residual Stress Effects, Strain, 2011, 47(SUPPL. 1), p 74–83.

M.L. Roessle and A. Fatemi, Strain-Controlled Fatigue Properties of Steels and Some Simple Approximations, Int. J. Fatigue, 2000, 22(6), p 495–511.

I. Čular, K. Vučković, D. Žeželj, and S. Glodež, Analytical Approach for Low and High Cycle Bending Fatigue Life Prediction of Carburized Gear Steel Specimens, Eng. Fail. Anal., 2020, 108, p 104328.

K. Vučković, I. Čular, R. Mašović, I. Galić, and D. Žeželj, Numerical Model for Bending Fatigue Life Estimation of Carburized Spur Gears with Consideration of the Adjacent Tooth Effect, Int. J. Fatigue, 2021, 153, p 106515.

A.M. Alshoaibi, Computational Simulation of 3D Fatigue Crack Growth under Mixed-Mode Loading, Appl. Sci., 2021, 11(13), p 5953.

H. Ma, J. Zeng, R. Feng, X. Pang, Q. Wang, and B. Wen, Review on Dynamics of Cracked Gear Systems, Eng. Fail. Anal., 2015, 55, p 224–245. https://doi.org/10.1016/j.engfailanal.2015.06.004

R. Citarella, V. Giannella, M. Lepore, and G. Dhondt, Dual Boundary Element Method and Finite Element Method for Mixed-Mode Crack Propagation Simulations in a Cracked Hollow Shaft, Fatigue Fract. Eng. Mater. Struct., 2018, 41(1), p 84–98.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (51775315), China and Key Technology Research and Development Program of Shandong Province, China (2019JZZY010114).

Author information

Authors and Affiliations

Contributions

XS: Conceptualization, writing—original draft. JZ: Conceptualization, writing—review and editing, project administration. YH: Supervision, project administration. ZL: Supervision, project administration. ZZ: Methodology. SS: Data curation, investigation. SG: Methodology. YL: Methodology.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, X., Zhao, J., Hu, Y. et al. The Prediction and Experimental Study of Bending Fatigue Life of Carburized Gears. J. of Materi Eng and Perform 33, 1051–1059 (2024). https://doi.org/10.1007/s11665-023-07999-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07999-y