Abstract

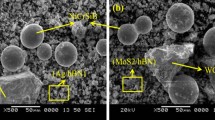

A microwave hybrid heating technique has been employed to develop NiCr-Mo-SiC composite cladding on titanium alloy (Grade-5/Ti-6Al-4 V/Titan-31). The developed claddings have been characterized for microstructural features, phase analysis, microhardness measurements, and 3D optical profile parameters by employing scanning electron microscopy, x-ray diffraction, Vickers microhardness tester, and 3D optical profilometer, respectively. Microwave clads have been subjected to linear reciprocator ball on plate wear test with static alumina indenter. Wear track parameters and friction coefficients have been studied. A dense microstructure with uniform distribution of hard phases and good metallurgical bonding with no visible pores and cracks has been obtained. Cladding exhibits nearly 2 times higher hardness than the base alloy. Coefficient of friction studies revealed that higher molybdenum content enhances internal lubricity.

Similar content being viewed by others

References

M. Flores and J. C. Sánchez-López (2021). Special Issue on Surface Engineering and Tribology. Mater. Lett., 295.

S. Kaushal et al., On Processing of Ni-WC Based Functionally Graded Composite Clads Through Microwave Heating, Mater. Manuf. Processes, 2018, 33(8), p 822–828.

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, and B.H. Channabasappa, Effect of Microwave Heating on Microstructure and Elevated Temperature Adhesive Wear Behavior of HVOF Deposited CoMoCrSi-Cr3C2 Composite Coating, Surf. Coat. Technol., 2019, 374, p 291–304. https://doi.org/10.1016/j.surfcoat.2019.05.056

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, and B.H. Channabasappa, Development and Sliding Wear Behavior of Co-Mo-Cr-Si Cladding through Microwave Heating, SILICON, 2019, 11, p 2975–2986. https://doi.org/10.1007/s12633-019-0084-5

A.K. Sharma and D. Gupta, On Microstructure and Flexural Strength of Metal-Ceramic Composite Cladding Developed Through Microwave Heating, Appl. Surf. Sci., 2012, 258(15), p 5583–5592.

C. Durga Prasad, S. Lingappa, S. Joladarashi, M.R. Ramesh, and B. Sachin, Characterization and Sliding Wear Behavior of CoMoCrSi+Flyash Composite Cladding Processed by Microwave irradiation, Mater. Today Proc., 2021, 46, p 2387–2391. https://doi.org/10.1016/j.matpr.2021.01.156

M. Bhattacharya and T. Basak, A Review on the Susceptor Assisted Microwave Processing of Materials, Energy, 2016, 97, p 306–338.

N. Bhoi et al. (2019). Microwave Material Processing: A Clean, Green and Sustainable Approach. Sustainable Engineering Products and Manufacturing Technologies, (2–3), Academic Press.

J. Mago et al., Investigation of Microwave Processing Parameters on Development of Ni-40Cr3C2 Composite clad and Their Characterization, Metall. Mater. Trans. A., 2020, 51A, p 4288–4300.

K. Holmberg, A. Mathews (2009) Coating tribology, properties, mechanisms, techniques and applications in surface engineering. Tribol. Interface Eng. Series, 56.

R. Dinesh, S. Rohan Raykar, T.L. Rakesh, M.G. Prajwal, M. Shashank Lingappa, and C. Durga Prasad, Feasibility Study on MoCoCrSi/ WC-Co Cladding Developed on Austenitic Stainless Steel Using Microwave Hybrid Heating, J. Mines, Metals Fuels, 2021 https://doi.org/10.18311/jmmf/2021/30113

F. Weng et al., Research Status of Laser Cladding on Titanium and its Alloys: A Review, Mater. Des., 2014, 58, p 412–425.

T. Naik, M. Mathapathi, C. Durga Prasad, H.S. Nithin, and M.R. Ramesh, Effect of Laser Post Treatment on Microstructural and Sliding Wear Behavior of HVOF Sprayed NiCrC and NiCrSi Coatings, Surface Rev. Lett., 2022, 29(1), p 225000. https://doi.org/10.1142/S0218625X2250007X

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, and M.S. Srinath, Microstructure and Tribological Resistance of Flame Sprayed CoMoCrSi/WC-CrC-Ni and CoMoCrSi/WC-12Co Composite Coatings Remelted by Microwave Hybrid Heating, J. Bio Tribo-Corrosion, 2020, 6, p 124. https://doi.org/10.1007/s40735-020-00421-3

S. Gudala, M.R. Ramesh, and S.S. Nallathambi, Evolution of Microstructure and High-Temperature Tribological Performance of Self-Lubricating Nickel-Based Composite Tungsten Inert Gas Coatings, J. Mater. Eng. Perform, 2021, 30, p 8080–8094. https://doi.org/10.1007/s11665-021-06008-4

G.A. Farotade et al., Microstructural Characterization and Surface Properties of Laser Clad Ni-ZrB2 Coatings on Ti-6Al-4V Alloy, Mater. Today, Proc., 2021, 38, p 1035–1039.

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, and B.H. Channabasappa, Microstructure and Tribological Behavior of Flame Sprayed and Microwave Fused CoMoCrSi/CoMoCrSi-Cr3C2 Coatings, Mater. Res. Express, 2019, 6, p 026512. https://doi.org/10.1088/2053-1591/aaebd9

C. Qi et al., The Influence of the Pre-Placed Powder Layers on the Morphology, Microscopic Characteristics and Microhardness of Ti-6Al-4V/WC MMC Coatings During Laser Cladding, Opt. Laser Technol., 2019, 119, 105572.

K. Monisha et al., Titanium Boride and Titanium Silicide Phase Formation by High Power Diode Laser Alloying of B4C and SiC Particles with Ti: Microstructure, Hardness and Wear Studies, Mater Today Commun, 2022, 31, 103741.

D. Gupta and A.K. Sharma, Investigation on Sliding Wear Performance of WC10Co2Ni Cladding Developed Through Microwave Irradiation, Wear, 2011, 271(9–10), p 1642–1650. https://doi.org/10.1016/j.wear.2010.12.037

C. Durga Prasad, M.R. Sharnappa Joladarashi, M.S. Ramesh, B.H. Srinath, and Channabasappa, Comparison of High Temperature Wear Behavior of Microwave Assisted HVOF Sprayed CoMoCrSi-WC-CrC-Ni/WC-12Co Composite Coatings, SILICON, 2020, 12, p 3027–3045. https://doi.org/10.1007/s12633-020-00398-1

S. Zafar and A.K. Sharma, Dry Sliding Wear Performance Of Nanostructured WC-12Co Deposited Through Microwave Cladding, Tribol. Int., 2015, 91, p 14–22.

M. Zhang et al., Effect of Molybdenum on the High Temperature Properties of TiC-TiB2 Reinforced Fe-Based Composite Laser Cladded Coatings, J. Alloys Compd., 2018, 742, p 383–390.

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, and B.H. Channabasappa, “Influence of Microwave Hybrid Heating on the Sliding Wear Behaviour of HVOF Sprayed CoMoCrSi Coating, Mater. Res. Express, 2018, 5, p 086519. https://doi.org/10.1088/2053-1591/aad44e

M. Szala et al. (2020). Cavitation Erosion and Sliding Wear of MCrAlY and NiCrMo Coatings Deposited by HVOF Thermal Spraying. Adv. Mater. Sci., 20, 2(64).

C. Durga Prasad, S. Joladarashi, M.R. Ramesh, and A. Sarkar, High Temperature Gradient Cobalt based Clad Developed Using Microwave Hybrid Heating, Am. Inst. Phys., 2018, 1943, p 020111. https://doi.org/10.1063/1.5029687

L. Chen et al., Microstructure and Properties of Metal Parts Remanufactured by Laser Cladding TiC and TiB2 Reinforced Fe-Based Coatings, Ceram. Int., 2022, 48, p 14127–14140.

Y. Zhao et al., Microstructures and Mechanical Properties of wear Resistant Titanium Oxide Coatings Deposited on Ti-6Al-4V Alloy Using Laser Cladding, J. Eur. Ceram. Soc., 2020, 40(3), p 798–810.

J. Yan et al., Microstructure and Wear Resistance of Plasma Sprayed Molybdenum Coating Reinforced by MoSi2 Particles, J. Therm. Spray Technol., 2016, 25(7), p 1322–1329.

C. S. Ramesh et al. (2018) Investigations on the Effect of Molybdenum and Molybdenum Silicon Carbide (Mo-10%SiC) Composite Coatings on Mild Steel Substrate Using HVOF Technique. Mater. Today, Proc. 5(11), 24422–24427.

I. Rustamov et al. (2018). “Fretting Wear Behaviour and Damage Mechanisms of Inconel X-750 Alloy in dry Contact Condition. J Tribol., TRIB-18–1343.

K. Aniolek et al., Sliding Wear Resistance of Oxide Layers Formed on a Titanium Surface During Thermal Oxidation, Wear, 2016, 356–357, p 23–29.

Q. Zhuang et al., Microstructure, Wear Resistance and Oxidation Behaviour of Ni-Ti-Si Coatings Fabricated on Ti6Al4V by Laser Cladding, Materials, 2017, 10, p 1248.

K. Wang et al. (2019) Microstructure and Properties of WC Reinforced Ni Based Composite Coatings with Y2O3 Addition on Titanium Alloy by Laser Cladding”. Sci. Technol. Weld. Join., ISSN: 1743–2936.

A. Pathania, S. Singh, D. Gupta, and V. Jain, Development and Analysis of Tribological Behavior of Microwave Processed EWAC+20% WC10Co2Ni Composite Cladding on Mild Steel Substrate, J. Manuf. Process., 2015, 20(1), p 79–87. https://doi.org/10.1016/j.jmapro.2015.09.007

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no declared conflicts of interest between the authors and the topic of this paper.

Ethical statement

The paper is the original work of all authors, has never been published, has only been submitted to this journal, and if approved, will not be submitted to any other journal in any language. It was created with the help of all authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sharanabasava, H., Prasad, C.D. & Ramesh, M.R. Characterization and Wear Behavior of NiCrMoSiC Microwave Cladding. J. of Materi Eng and Perform 33, 763–775 (2024). https://doi.org/10.1007/s11665-023-07998-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07998-z