Abstract

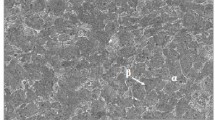

Titanium alloys are used in many areas from aviation, aerospace and automobile industries to implant and prosthesis production with their high strength, high corrosion resistance and excellent fatigue strength. Having such a wide area of usage brings the necessity of joining titanium alloys, and the most used joining method is welding. However, when titanium alloys are joined with the traditional fusion welding method, brittle structure, resistance to high residual stresses and undesirable deformation problems are encountered due to uneven heating and cooling. For these reasons, in this study, titanium alloys were joined by friction welding via using applying different friction pressures, and then, macro- and microstructure studies as well as hardness, tensile and torsion tests were applied to the produced joints. As a result of microstructure studies, it was observed that the increased heat input due to the increased friction pressure caused the grains to grow, while increasing plastic deformation with increasing friction pressure prevented this growth and caused the grains to become thinner. In all welded joints produced, the highest hardness was obtained in the weld metal due to dynamic recrystallization caused by plastic deformation caused by friction. While it was determined that the tensile strength of the welded joints was close to each other, it was observed that the tensile strength of all samples was higher than the tensile strength of the base metal. Torsion test results were also close to each other, similar to the tensile test results.

Similar content being viewed by others

References

M. Kimura, T. Iijima, M. Kusaka, K. Kaizu, and A. Fuji, Joining Phenomena and Tensile Strength of Friction Welded Joint Between Pure Titanium and Low Carbon Steel, Mater. Des., 2014, 55, p 152–164.

H. Bingzhou, W. Shaogang, and L. Kang, Effect of Different Welding Procedures on Microstructure and Mechanical Property of TA15 Titanium Alloy Joint, High Temp. Mater. Process. (London), 2022, 41, p 137–149.

I. Eizaguirre, J.L. Barreda, X. Azpiroz, F. Santamaria, and A.M. Irisarri, Fracture Toughness of the Weldments of Thick Plates of Two Titanium Alloys Titanium’99, Sci. Technol., 2009, 3, p 1734–1741.

A. Awais, D. Honggang, X. Yueqing, and L. Peng, Lap Joining 5052 Aluminum Alloy to Ti6Al4V Titanium Alloy by GTAW Process with AlSi12 Filler Wire, China Weld., 2020, 29(3), p 1–8.

B. Shashi, S. Tarunpreet, K. Virinder, S. Shankar, and B.K. Ashok, A Systematic Review on Recent Progress in Advanced Joining Techniques of the Lightweight Materials, AIMS Mater. Sci., 2021, 8(1), p 62–81.

P. Swastik, I. Soppa, and N. Ravi, Investigation of Machinability Criteria of Ti Gr-2 Using a New Design Micro-Texture cutting İnserts with Graphene Based Solid Lubrication, Sådhanå, 2022, 47, p 175. https://doi.org/10.1007/s12046-022-01952-w

L. Aleksander, Laser Welding of Titanium Alloy Ti6Al4V Using a Disk Laser, Sci. Proc. Ix Int. Congr. Mach. Technol. Mater., 2012, 1, p 23–26.

E. Ranatowski, Weldability of Titanium and its Alloys—Progress in Joining, Adv. Mater. Sci., 2008, 8, p 69–76.

L. Wenya, S. Juandi, M. Tiejun, F. Yan, and K. KeeHyun, Abnormal Microstructure in the Weld Zone of Linear Friction Welded Ti-6.5Al-3.5Mo-1.5Zr-0.3Si Titanium Alloy Joint and İts İnfluence on Joint Properties, Mater. Sci. Eng. A, 2014, 599, p 38–45.

A. Mohammadreza, Investigation of Spindle Rotation Rate Effects on the Mechanical Behavior of Friction Stir Welded Ti 4Al 2V Alloy, J. Weld. Join., 2020, 38(1), p 81–91.

M. Junaid, M.N. Baig, M. Shamir, F.N. Khan, K. Rehman, and J. Haider, A Comparative Study of Pulsed Laser and Pulsed TIG Welding of Ti-5Al-2.5Sn Titanium Alloy Sheet, J. Mater. Process. Technol., 2017, 242, p 24–38.

W. Yanni, L. Jinglong, X. Jiangtao, H. Fu, Z. Fusheng, and R.H. Syed, Joining Aluminum to Titanium Alloy by Friction Stir Lap Welding with Cutting Pin, Mater. Charact., 2012, 71, p 1–5.

R.G. Ananda and N. Ramanaiah, Dissimilar Metals AISI 304 Steel and AA 2219 Aluminium Alloy Joining by Friction Welding Method, Mater. Today Proc., 2022 https://doi.org/10.1016/j.asej.2022.101853

P. Anitha, C.M. Manik, V. Saravanan, and S. Rajakumar, Investigation of Mechanical Properties of Friction-Welded AISI 304 with AISI 430 Dissimilar Steels, Mater. Phys. Chem., 2018, 1, p 1–6.

G. Peihao, Q. Guoliang, and Z. Jun, Numerical and Experimental İnvestigation on Friction Welding of Austenite Stainless Steel and Middle Carbon Steel, J. Manuf. Process., 2019, 47, p 83–97.

R.K. Matthew, R.S. Steven, C.A. Daniel, F. Jeffrey, and H. Ryan, Experimental İnvestigation of Linear Friction Welding of AISI 1020 Steel With Pre-heating, J. Manuf. Process., 2019, 39, p 26–39.

A. Lisiecki, Welding of Titanium Alloy by Different Types of Lasers, Arch. Mater. Sci. Eng., 2012, 58(2), p 209–218.

Z. Wei and K.G. Chew, Effect of Welding on Impact Toughness of Butt-Joints in a Titanium Alloy, Mater. Sci. Eng. A, 2003, 347, p 180–185.

J. Niagaj, Peculıarıtıes of A-Tig Weldıng of Tıtanıum and Its Alloys, Arch. Metall. Mater., 2012, 57(1), p 39–45.

F.C. Liu, H. Liu, K. Nakata, N. Yamamoto, and J. Liao, Investigation on Friction stir Welding Parameter Design for Lap Joining of Pure Titanium, Proc. 1st Int. Joint Symp. Join. Weld., 2013 https://doi.org/10.1533/978-1-78242-164-1.159

A.S. Sundar, T.V. Vardhan, and A. Kumar, Microstructural Characterization of Aluminium-Titanium Friction Stir Welds, Mater. Today Proc., 2022, 62(10), p 5845–5849.

M. Balasubramanian, S. Murali, C. Hemadri, and R. Kumar, A New Method of Dissimilar Friction Welding of Titanium to Stainless Steel, Mater. Today Proc., 2021, 46, p 3644–3647.

R. Kumar and M. Balasubramanian, Analysis and Comparison of Diffusion Bonded and Friction Welded Ti-6Al-4V and Stainless Steel Joints with Copper as İnterlayer, Mater. Today Proc., 2020, 21, p 1467–1473.

X. Wang, W. Li, T. Ma, X. Yang, and A. Vairis, Effect of Welding Parameters on the Microstructure and Mechanical Properties of Linear Friction Welded Ti-6.5Al-3.5Mo-1.5Zr-0.3Si Joints, J. Manuf. Process., 2019, 46, p 100–108.

M. Kimura, T. Iijima, M.K. Kusaka, A. Kaizu, and A. Fuji, Joining Phenomena and Tensile Strength of Friction Welded Joint Between Ti-6Al-4V Titanium Alloy and Low Carbon Steel, J. Manuf. Process., 2016, 24, p 203–211.

R. Palanivel, L. Dinaharan, and R.F. Laubscher, Assessment of Microstructure and Tensile Behavior of Continuous Drive Friction Welded Titanium Tubes, Mater. Sci. Eng. A, 2017, 687, p 249–258.

S. Rajan, P. Wanjara, J. Gholipour, and A.S. Kabir, Joining of Dissimilar Alloys Ti-6Al-4V and Ti-6Al-2Sn-4Zr-2Mo-0.1Si Using Linear Friction Welding, Materials, 2020, 13, p 3664. https://doi.org/10.3390/ma13173664

A. Vairis and M. Frost, High Frequency Linear Friction Welding of a Titanium Alloy, Wear, 1998, 217, p 117–131.

H.S. Patil and D.C. Patel, Characterizations of TIG Welded Joints of Unalloyed Commercially Pure Titanium Gr-2 for Weld Process Parameters, Fratt. ed Int. Strutt., 2019, 48, p 377–384.

S. Apay, Weldability of Grade 2 Titanium Sheets with Pulsed Nd:YAG Microlaser Welding Filler and Without Filler, Mater. Sci., 2022 https://doi.org/10.5755/j02.ms.28372

X.Y. Wang, W.Y. Li, T.J. Ma, and A. Vairis, Characterisation Studies of Linear Friction Welded Titanium Joints, Mater. Des., 2017, 116, p 115–126.

R. Palanivel, R.F. Laubscher, I. Dinaharan, and D.G. Hattingh, Microstructure and Mechanical Characterization of Continuous Drive Friction Welded Grade 2 Seamless Titanium Tubes at Different Rotational Speeds, Int. J. Press. Vessels Pip., 2017, 154, p 17–28.

Y. Wu, C. Zhang, J. Zhou, W. Liang, and Y. Li, Analysis of the Microstructure and Mechanical Properties during Inertia Friction Welding of the Near-α TA19 Titanium Alloy, Chin. J. Mech. Eng., 2020, 33(88), p 1–13. https://doi.org/10.1186/s10033-020-00507-6

X. Wang, W. Li, T. Ma, X. Yang, and A. Vairis, Microstructural Evolution and Mechanical Properties of a Linear Friction Welded Two-Phase Ti-6.5Al-3.5Mo-1.5Zr-0.3Si Titanium Alloy Joint, Mater. Sci. Eng. A, 2019, 743, p 12–23.

Y. Ji, S. Wu, and D. Zhao, Microstructure and Mechanical Properties of Friction Welding Joints with Dissimilar Titanium Alloys, Metals, 2016 https://doi.org/10.3390/met6050108

J.W. Choi, Y. Aoki, K. Ushioda, and H. Fujii, Effect of the Welding Parameters on Microstructure and Mechanical Properties of Linear Friction Welded Ti-6Al-4V Alloy, J. Manuf. Process., 2022, 75, p 651–663.

Z. Li, S. Zhao, Z. Li, M. Wang, F. Wu, H. Wang, and J. Zhou, Investigation of the Mechanical Properties of Inertia-Friction-Welded Joints of TC21 Titanium Alloy, Processes, 2022, 10(752), p 2–9.

W. Li, J. Suo, T. Ma, Y. Feng, and K. Kim, Abnormal Microstructure in the Weld Zone of Linear Friction Welded Ti-6.5Al-3.5Mo-1.5Zr-0.3Si Titanium Alloy Joint and İts İnfluence on Joint Properties, Mater. Sci. Eng. A, 2014, 599, p 38–45.

M.S. Gogheri, M. Kasıri-Asgarani, H.R. Bakhsheshi-Rad, H. Ghayour, and M. Rafıei, Mechanical Properties, Corrosion Behavior and Biocompatibility of Orthopedic Pure Titanium-Magnesium Alloy Screw Prepared by Friction Welding, Trans. Nonferrous Met. Soc. China, 2020, 30, p 2952–2966.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yürük, A. The Effect of Different Friction Pressure on the Microstructural and Mechanical Properties of Ti Gr2 Titanium Alloy. J. of Materi Eng and Perform 32, 8678–8686 (2023). https://doi.org/10.1007/s11665-023-07974-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07974-7