Abstract

To improve the mechanical properties of CoCrNi system multicomponent alloys, we prepared a series of (CoCrNi)100-x(TiV)x (x = 5, 10, 20, 30, and 40) multicomponent alloys by simultaneously adding Ti and V elements into the CoCrNi-based alloy at a fixed stoichiometric ratio (1:1). Results showed that the phase components of the prepared alloys with x ≤ 10 were composed of a typical single face-centered cubic phase. The elements in the alloy (CoCrNi)95(TiV)5 were uniformly distributed, whereas the Ti in the (CoCrNi)90(TiV)10 alloy was segregated in the based microstructure. The yield strength of (TiV)10 alloy (678 MPa) was approximately two times that of (TiV)5 alloy (371 MPa), with non-sacrificed plasticity (> 50%). The enhancement of yield strength of the alloy was attributed to precipitation strengthening caused by the Ti segregation and the solid solution strengthening of TiV. Stiff phases σ, η, and body-centered cubic were formed in the alloys with higher TiV content and distributed in both the dendrites and inter-dendrites regions, thus increasing the compression strength of the alloy. The maximum compression strength was 2220 MPa of the alloy with x = 40.

Similar content being viewed by others

References

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A, 2004, 375–377, p 213–218.

B.S. Murty, J.W. Yeh, S. Ranganathan, and P.P. Bhattacharjee, A Brief History of Alloys and the Birth of High-Entropy Alloys, High-Entropy Alloys, 2nd ed. Elsevier, Amsterdam, 2019, p 1–12

Y.F. Ye, Y.H. Zhang, Q.F. He, Y. Zhuang, S. Wang, S.Q. Shi, A. Hu, J. Fan, and Y. Yang, Atomic-Scale Distorted Lattice in Chemically Disordered Equimolar Complex Alloys, Acta Mater., 2018, 150, p 182–194.

K.Y. Tsai, M.H. Tsai, and J.W. Yeh, Sluggish diffusion in Co-Cr-Fe-Mn-Ni high-entropy alloys, Acta Mater., 2013, 61(13), p 4887–4897.

J.W. Yeh, Alloy Design Strategies and Future Trends in High-Entropy Alloys, JOM, 2013, 65(12), p 1759–1771.

A.S. Tirunilai, T. Hanemann, C. Reinhart, V. Tschan, K.P. Weiss, G. Laplanche, J. Freudenberger, M. Heilmaier, and A. Kauffmann, Comparison of Cryogenic Deformation of the Concentrated Solid Solutions CoCrFeMnNi, CoCrNi and CoNi, Mater. Sci. Eng. A, 2020, 783, p 139290.

S. Gangireddy, B. Gwalani, K. Liu, R. Banerjee, and R.S. Mishra, Microstructures with Extraordinary Dynamic Work Hardening and Strain Rate Sensitivity in Al0.3CoCrFeNi High Entropy Alloy, Mater. Sci. Eng. A, 2018, 734, p 42–50.

D. Wei, W. Gong, L. Wang, B. Tang, T. Kawasaki, S. Harjo, and H. Kato, Strengthening of High-Entropy Alloys via Modulation of Cryo-Pre-Straining-Induced Defects, J. Mater. Sci. Technol., 2022, 129, p 251–260.

D. Wei, L. Wang, and Y. Zhang, Metalloid Substitution Elevates Simultaneously the Strength and Ductility of Face-Centered-Cubic High-Entropy Alloys, Acta Mater., 2022, 225, p 117571.

J. Saha and P.P. Bhattacharjee, Influences of Thermomechanical Processing by Severe Cold and Warm Rolling on the Microstructure, Texture, and Mechanical Properties of an Equiatomic CoCrNi Medium-Entropy Alloy, J. Mater. Eng. Perform., 2021, 30(12), p 8956–8971.

H.L. Yi, D.X. Wei, Y.C. Wang, L.Q. Wang, M.Y. Fang, K. Yang, and H. Kato, Hot Deformation and Dynamic Recrystallization Behavior of CoCrNi and (CoCrNi)94Ti3Al3 Medium Entropy Alloys, Metals, 2020, 10(10), p 1341.

S. Yoshida, T. Bhattacharjee, Y. Bai, and N. Tsuji, Friction Stress and Hall-Petch Relationship in CoCrNi Equi-atomic Medium Entropy Alloy Processed by Severe Plastic Deformation and Subsequent Annealing, Scr. Mater., 2017, 134, p 33–36.

K. Xiang, L. Chai, C. Zhang, H. Guan, Y. Wang, Y. Ma, Q. Sun, and Y. Li, Investigation of Microstructure and Wear Resistance of Laser-clad CoCrNiTi and CrFeNiTi Medium-Entropy Alloy Coatings on Ti Sheet, Opt. Laser Technol., 2022, 145, p 107518.

W. Lu, X. Luo, Y. Yang, and B. Huang, Effects of Nb Additions on Structure and Mechanical Properties Evolution of CoCrNi Medium-Entropy Alloy, Mater. Express, 2019, 9(4), p 291–298.

D.H. Chung, X.D. Liu, and Y. Yang, Fracture of Sigma Phase Containing Co-Cr-Ni-Mo Medium Entropy Alloys, J. Alloys Compd., 2020, 846, p 156189.

Q. Hu, F.C. Liu, Q.L. Fan, H. Du, G. Liu, G.-H. Wang, Z.T. Fan, and X.W. Liu, Effect of Al on Microstructure and Mechanical Properties of Cast CrCoNi Medium-Entropy Alloy, China Foundry, 2018, 15(4), p 253–262.

Y. Du, X. Pei, Z. Tang, F. Zhang, Q. Zhou, H. Wang, and W. Liu, Mechanical and Tribological Performance of CoCrNiHf Eutectic Medium-Entropy Alloys, J. Mater. Sci. Technol., 2021, 90, p 194–204.

W. Lu, X. Luo, Y. Yang, J. Zhang, and B. Huang, Effects of Al Addition on Structural Evolution and Mechanical Properties of the CrCoNi Medium-Entropy Alloy, Mater. Chem. Phys., 2019, 238, p 121841.

Y.L. Zhao, T. Yang, Y. Tong, J. Wang, J.H. Luan, Z.B. Jiao, D. Chen, Y. Yang, A. Hu, C.T. Liu, and J.J. Kai, Heterogeneous Precipitation Behavior and Stacking-Fault-Mediated Deformation in a CoCrNi-Based Medium-Entropy Alloy, Acta Mater., 2017, 138, p 72–82.

D.D. Zhang, J.Y. Zhang, J. Kuang, G. Liu, and J. Sun, Superior Strength-Ductility Synergy and Strain Hardenability of Al/Ta Co-doped NiCoCr Twinned Medium Entropy Alloy for Cryogenic Applications, Acta Mater., 2021, 220, p 117288.

Y. Pan, A. Dong, Y. Zhou, D. Du, D. Wang, G. Zhu, and B. Sun, Enhanced Strength-Ductility Synergy in a Novel V-Containing γ″-Strengthened CoCrNi-Based Multi-Component Alloy, Mater. Sci. Eng. A, 2021, 816, p 141289.

B. Han, J. Wei, Y. Tong, D. Chen, Y. Zhao, J. Wang, F. He, T. Yang, C. Zhao, Y. Shimizu, K. Inoue, Y. Nagai, A. Hu, C.T. Liu, and J.J. Kai, Composition Evolution of Gamma Prime Nanoparticles in the Ti-Doped CoFeCrNi High Entropy Alloy, Scr. Mater., 2018, 148, p 42–46.

B. Yin, F. Maresca, and W.A. Curtin, Vanadium is an Optimal Element for Strengthening in both fcc and bcc High-Entropy Alloys, Acta Mater., 2020, 188, p 486–491.

Z. Cai, G. Jin, X. Cui, Y. Li, Y. Fan, and J. Song, Experimental and Simulated Data about Microstructure and Phase Composition of a NiCrCoTiV High-Entropy Alloy Prepared by Vacuum Hot-Pressing Sintering, Vacuum, 2016, 124, p 5–10.

L. Zhang, X. Du, L. Zhang, W. Li, Y. Liang, J. Yu, N. Zou, G. Wan, Y. Tang, G. Duan, and B. Wu, Achieving Ultra-High Strength in a Precipitation-Hardened CoCrNi-Based Medium-Entropy Alloy with Partially Recrystallized Microstructure and Heterogeneous Grains, Vacuum, 2021, 188, p 110169.

D. Petroglou, A. Poulia, C. Mathiou, E. Georgatis, and A.E. Karantzalis, A Further Examination of MoTaxNbVTi (x = 0.25, 0.50, 0.75 and 1.00 at.%) High-Entropy Alloy System: Microstructure, Mechanical Behavior and Surface Degradation Phenomena, Appl. Phys. A Mater., 2020, 126(5), p 126364.

Y. Chen, W. Liu, H. Wang, J. Xie, T. Zhang, L. Yin, and Y. Huang, Effect of Ti Content on the Microstructure and Properties of CoCrFeNiMnTix High Entropy Alloy, Entropy (Basel), 2022, 24(2), p 241.

Z. Wu, H. Bei, G.M. Pharr, and E.P. George, Temperature Dependence of the Mechanical Properties of Equiatomic Solid Solution Alloys with Face-Centered Cubic Crystal Structures, Acta Mater., 2014, 81, p 428–441.

Y. Cai, Y. Tong, Y. Hu, H. Huang, X. Zhang, M. Hua, S. Xu, Y. Mei, C. Ma, and Z. Li, Wear-Resistant TiC Strengthening CoCrNi-Based High-Entropy Alloy Composite, Materials, 2021, 14(16), p 4665.

F. Průša, M. Cabibbo, A. Šenková, V. Kučera, Z. Veselka, A. Školáková, D. Vojtěch, J. Cibulková, and J. Čapek, High-Strength Ultrafine-Grained CoCrFeNiNb High-Entropy Alloy Prepared by Mechanical Alloying: Properties and Strengthening Mechanism, J. Alloys Compd., 2020, 835, p 155308.

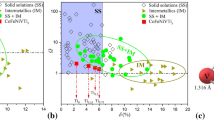

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Solid-Solution Phase Formation Rules for Multi-component Alloys, Adv. Eng. Mater., 2008, 10(6), p 534–538.

X. Yang and Y. Zhang, Prediction of High-Entropy Stabilized Solid-Solution in Multi-component Alloys, Mater. Chem. Phys., 2012, 132(2–3), p 233–238.

S. Guo and C.T. Liu, Phase Stability in High Entropy Alloys: Formation of Solid-Solution Phase or Amorphous Phase, Prog. Nat. Sci. Mater. Int., 2011, 21(6), p 433–446.

S. Guo, C. Ng, J. Lu, and C.T. Liu, Effect of Valence Electron Concentration on Stability of fcc or bcc Phase in High Entropy Alloys, J. Appl. Phys., 2011, 109(10), p 103505.

A. Takeuchi and A. Inoue, Mixing Enthalpy of Liquid Phase Calculated by Miedema’s Scheme and Approximated with Sub-Regular Solution Model for Assessing Forming Ability of Amorphous and Glassy Alloys, Intermetallics, 2010, 18(9), p 1779–1789.

M.-H. Tsai, K.-Y. Tsai, C.-W. Tsai, C. Lee, C.-C. Juan, and J.-W. Yeh, Criterion for Sigma Phase Formation in Cr- and V-Containing High-Entropy Alloys, Mater. Res. Lett., 2013, 1(4), p 207–212.

F. Otto, Y. Yang, H. Bei, and E.P. George, Relative Effects of Enthalpy and Entropy on the Phase Stability of Equiatomic High-Entropy Alloys, Acta Mater., 2013, 61(7), p 2628–2638.

Y.H. Jo, W.M. Choi, D.G. Kim, A. Zargaran, K. Lee, H. Sung, S.S. Sohn, H.S. Kim, B.J. Lee, and S. Lee, Utilization of Brittle σ Phase for Strengthening and Strain Hardening in Ductile VCrFeNi High-Entropy Alloy, Mater. Sci. Eng. A, 2019, 743, p 665–674.

D. You, G. Yang, Y.-H. Choa, and J.-K. Kim, Crack-Resistant σ/FCC Interfaces in the Fe40Mn40Co10Cr10 High Entropy Alloy with the Dispersed σ-Phase, Mater. Sci. Eng. A, 2022, 831, p 142039.

J.M. Joubert, Crystal Chemistry and Calphad Modeling of the σ Phase, Prog. Mater. Sci., 2008, 53(3), p 528–583.

A.C. Yeh, Y.J. Chang, C.W. Tsai, Y.C. Wang, J.W. Yeh, and C.M. Kuo, On the Solidification and Phase Stability of a Co-Cr-Fe-Ni-Ti High-Entropy Alloy, Metall. Mater. Trans. A, 2013, 45(1), p 184–190.

Y. Chen, Z. Xu, M. Wang, Y. Li, C. Wu, and Y. Yang, A Single-Phase V0.5Nb0.5ZrTi Refractory High-Entropy Alloy with Outstanding Tensile Properties, Mater. Sci. Eng. A, 2020, 792, p 139774.

O.N. Senkov, J.M. Scott, S.V. Senkova, D.B. Miracle, and C.F. Woodward, Microstructure and Room Temperature Properties of a High-Entropy TaNbHfZrTi Alloy, J. Alloys Compd., 2011, 509(20), p 6043–6048.

X. Yan and Y. Zhang, A body-Centered Cubic Zr50Ti35Nb15 Medium-Entropy Alloy with Unique Properties, Scr. Mater., 2020, 178, p 329–333.

N. Ramakrishnan, An Analytical Study on Strengthening of Particulate Reinforced Metal Matrix Composites, Acta Mater., 1996, 44(1), p 69–77.

Z. Zhang and D. Chen, Consideration of Orowan Strengthening Effect in Particulate-Reinforced Metal Matrix Nanocomposites: A Model for Predicting their Yield Strength, Scr. Mater., 2006, 54(7), p 1321–1326.

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, and Z.P. Lu, Effects of Al Addition on Structural Evolution and Tensile Properties of the FeCoNiCrMn High-Entropy Alloy System, Acta Mater., 2014, 62, p 105–113.

O.N. Senkov, D.B. Miracle, K.J. Chaput, and J.-P. Couzinie, Development and exploration of refractory high entropy alloys–A review, J. Mater. Res., 2018, 33(19), p 3092–3128.

G.A. Salishchev, M.A. Tikhonovsky, D.G. Shaysultanov, N.D. Stepanov, A.V. Kuznetsov, I.V. Kolodiy, A.S. Tortika, and O.N. Senkov, Effect of Mn and V on Structure and Mechanical Properties of High-Entropy Alloys Based on CoCrFeNi System, J. Alloys Compd., 2014, 591, p 11–21.

G.J. Li, J. Li, and X. Luo, Effects of High Temperature Treatment on Microstructure and Mechanical Properties of Laser-clad NiCrBSi/WC Coatings on Titanium Alloy Substrate, Mater. Charact., 2014, 98, p 83–92.

M. Xu, J. Wang, L. Wang, L. Yang, and J. Yi, Influence of Annealing on Microstructure and Mechanical Properties of Equiatomic CoCrNiTiV 3d Transition Metal High Entropy Alloy Ingots, Mater. Trans., 2021, 62(11), p 1609–1613.

Acknowledgments

Financial supports from Changzhou Science and Technology Bureau (CJ20210065, CQ20210086, No. CJ20220057) and Graduate Practice and Innovation Projects of Jiangsu University of Technology (XSJCX22_08) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lu, L., He, Q., Wang, L. et al. Superior Strength Enhancement of Ti/V Co-Doped CoCrNi Multicomponent Alloys. J. of Materi Eng and Perform 32, 10591–10601 (2023). https://doi.org/10.1007/s11665-023-07896-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07896-4