Abstract

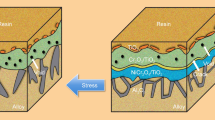

The present work investigated the influence of TiC nanoparticles on the microstructure and corrosion performance of a cast superalloy K4169. The eutectic Laves phase is reduced and the as-cast grain size is refined by adding 0.02 wt.% TiC. The formation of δ phases (Ni3Nb) during heat treatments is also suppressed. Thus, the K4169 superalloy with TiC nanoparticles shows better corrosion resistance in sulfuric acid solution (10 vol.% H2SO4 solution). This work provides a strategy to effectively improve the corrosion resistance of conventional cast superalloys.

Similar content being viewed by others

Data Availability

All data generated or used during the study are available from the corresponding author upon reasonable request.

References

A. Nowotnik, K. Kubiak, J. Sieniawski, P. Rokicki, P. Pedrak, and G. Mrówka-Nowotnik, Development of Nickel Based Superalloys for Advanced Turbine Engines, Mater. Sci. Forum., 2014, 783–786, p 2491–2496. https://doi.org/10.4028/www.scientific.net/msf.783-786.2491

B. Sutton, E. Herderick, R. Thodla, M. Ahlfors, and A. Ramirez, Heat Treatment of Alloy 718 Made by Additive Manufacturing for Oil and Gas Applications, Jom, 2019, 71, p 1134–1143. https://doi.org/10.1007/s11837-018-03321-7

K. Patel, M. Sadeghilaridjani, M. Pole, and S. Mukherjee, Hot Corrosion Behavior of Refractory High Entropy Alloys in Molten Chloride Salt for Concentrating Solar Power Systems, Sol. Energy Mater. Sol. Cells, 2021, 230, p 111222. https://doi.org/10.1016/j.solmat.2021.111222

S. Soller, A. Barata, S. Beyer, A. Dahlhaus, D. Guichard, E. Humbert, J. Kretschmer, and W. Zeiss, Selective laser melting of Inconel 718 and stainless steel injectors for liquid rocket engines, Sp. Propuls. 2016 Proc. (2016). https://www.researchgate.net/publication/303331194.

Y. Wang, W. Liu, D. Wang, C. Yu, J. Xu, H. Lu, and J. Chen, Simultaneously Enhanced Strength and Ductility of TIG Welds in Inconel 718 Super-Alloy Via Ultrasonic Pulse Current, Mater. Sci. Eng. A, 2021, 807, p 140894. https://doi.org/10.1016/j.msea.2021.140894

S. Hu, H. Finklea and X. Liu, A Review on Molten Sulfate Salts Induced Hot Corrosion, J. Mater. Sci. Technol., 2021, 90, p 243–254. https://doi.org/10.1016/j.jmst.2021.03.013

Y. Le Guével, B. Grégoire, M.J. Cristóbal, X. Feaugas, A. Oudriss, and F. Pedraza, Dissolution and Passivation of Aluminide Coatings on Model and Ni-Based Superalloy, Surf. Coat. Technol., 2019, 357, p 1037–1047. https://doi.org/10.1016/j.surfcoat.2018.10.090

L. Liu, Y. Li, and F. Wang, Electrochemical Corrosion Behavior of Nanocrystalline Materials-A Review, J. Mater. Sci. Technol., 2010, 26, p 1–14. https://doi.org/10.1016/S1005-0302(10)60001-1

C. Ma, C. Zhou, and J. Sun, Electrochemical Corrosion Behavior of the Cobalt Modified Aluminide Coating in 3.5 wt.% NaCl Solutions, Prog. Nat. Sci. Mater. Int., 2018, 28(1), p 85–89. https://doi.org/10.1016/j.pnsc.2018.01.009

G.S. Mahobia, N. Paulose, and V. Singh, Hot Corrosion Behavior of Superalloy IN718 at 550 and 650 C, J. Mater. Eng. Perform., 2013, 22, p 2418–2435. https://doi.org/10.1007/s11665-013-0532-0

R.A. Rapp, Hot Corrosion of Materials: A Fluxing Mechanism?, Corros. Sci., 2002, 44, p 209–221. https://doi.org/10.1016/S0010-938X(01)00057-9

M. Wang, M. Song, G.S. Was, and J.L. Nelson, The Roles of Thermal Mechanical Treatment and δ Phase in the Stress Corrosion Cracking of Alloy 718 in Primary Water, Corros. Sci., 2019, 160, p 108168. https://doi.org/10.1016/j.corsci.2019.108168

Y. Tang, X. Shen, Y. Qiao, L. Yang, J. Chen, D. Lu, and Z. Zhang, Corrosion Behavior of a Selective Laser Melted Inconel 718 Alloy in a 3.5 wt.% NaCl Solution, J. Mater. Eng. Perform., 2021, 30, p 5506–5514. https://doi.org/10.1007/s11665-021-05909-8

L.N. Zhang and O.A. Ojo, Corrosion Behavior of Wire Arc Additive Manufactured Inconel 718 Superalloy, J. Alloys Compd., 2020, 829, p 154455. https://doi.org/10.1016/j.jallcom.2020.154455

J.J. Li, Z. Zhao, P. Bai, H. Qu, B. Liu, L. Li, L. Wu, R. Guan, H. Liu, and Z. Guo, Microstructural Evolution and Mechanical Properties of IN718 Alloy Fabricated by Selective Laser Melting Following Different Heat Treatments, J. Alloys Compd., 2019, 30, p 1134–1143. https://doi.org/10.1016/j.addma.2019.100875

B. Zhang, M. Xiu, Y.T. Tan, J. Wei, and P. Wang, Pitting Corrosion of SLM Inconel 718 Sample Under Surface and Heat Treatments, Appl. Surf. Sci., 2019, 490, p 556–567. https://doi.org/10.1016/j.apsusc.2019.06.043

L.C.M. Valle, A.I.C. Santana, M.C. Rezende, J. Dille, O.R. Mattos, and L.H. de Almeida, The Influence of Heat Treatments on the Corrosion Behaviour of Nickel-Based Alloy 718, J. Alloys Compd., 2019, 809, p 151781. https://doi.org/10.1016/j.jallcom.2019.151781

M. Amirjan, M. Bozorg, and H. Sakiani, Investigation of Microstructure and Corrosion Behavior of IN718 Superalloy Fabricated by Selective Laser Melting, Mater. Chem. Phys., 2021, 263, p 124368. https://doi.org/10.1016/j.matchemphys.2021.124368

X. You, Y. Tan, L. Zhao, Q. You, Y. Wang, F. Ye, and J. Li, Effect of Solution Heat Treatment on Microstructure and Electrochemical Behavior of Electron Beam Smelted Inconel 718 Superalloy, J. Alloys Compd., 2018, 741, p 792–803. https://doi.org/10.1016/j.jallcom.2018.01.159

S. Luo, W. Huang, H. Yang, J. Yang, Z. Wang, and X. Zeng, Microstructural Evolution and Corrosion Behaviors of Inconel 718 Alloy Produced by Selective Laser Melting Following Different Heat Treatments, Addit. Manuf., 2019, 30, p 100875. https://doi.org/10.1016/j.addma.2019.100875

X. Liu, Z. Liu, L. Zhang, Q. Zhao, and Q. Jiang, Increased Tensile Strength and Elongation of the Ni-Fe Based Polycrystalline Cast Superalloy Via the Trace Addition of TiC Nanoparticles, Mater. Sci. Eng. A, 2021, 827, p 141988. https://doi.org/10.1016/j.msea.2021.141988

R. Geng, S.Q. Jia, F. Qiu, Q.L. Zhao, and Q.C. Jiang, Effects of Nanosized TiC and TiB2 Particles on the Corrosion Behavior of Al-Mg-Si Alloy, Corros. Sci., 2020, 167, p 108479. https://doi.org/10.1016/j.corsci.2020.108479

W.S. Tian, Q.L. Zhao, Q.Q. Zhang, F. Qiu, and Q.C. Jiang, Enhanced Strength and Ductility at Room and Elevated Temperatures of Al-Cu Alloy Matrix Composites Reinforced with Bimodal-Sized TiCp Compared with Monomodal–Sized TiCp, Mater. Sci. Eng. A, 2018, 724, p 368–375. https://doi.org/10.1016/j.msea.2018.03.106

O. Golenishcheva, M. Oechsner, A. Aghajani, G. Andersohn, J. Kloewer, Influence of Delta-phase Precipitation on the Pitting Performance of UNS (N07718), Corros. 2014. (2014) NACE-2014-3895.

Acknowledgments

This work was funded by the National Natural Science Foundation of China (Grant No. 51790483).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sun, S., Zhang, L., Liu, X. et al. Nanoparticle Additions Improve the Corrosion Performance of Ni-Cr-Fe-Based Cast Superalloys. J. of Materi Eng and Perform 32, 8154–8161 (2023). https://doi.org/10.1007/s11665-022-07710-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07710-7