Abstract

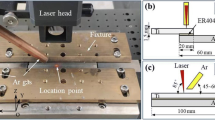

TM52/Q235 dissimilar materials were welded by transient liquid phase diffusion bonding (TLP) with BNi2 foil. The effects of welding temperature on the interface structure, mechanical properties, electrochemical properties and corrosion surface morphology of joints were studied. At the same time, the connection mechanism of TM52/Q235 welded joint is established. The results show that TM52/Q235 can achieve good metallurgical bonding. When the welding temperature is 1100 °C, the shear strength of the joint is the largest, reaching 425.06 MPa. And the shear fracture shows obvious ductile fracture characteristics, and the failure is located at the side of TM52. With the increase in welding temperature, the corrosion resistance of joints increases at first and then decreases. Especially at 1100 °C, the passivation film formed at the weld is the densest and the corrosion rate is the lowest. And the electrochemical corrosion products are mainly composed of Fe2O3, Fe3O4 and FeOOH.

Similar content being viewed by others

References

J.A.M. Ferreira, M.A. Pina Amaral, F.V. Antunes et al., A Study on Themechanical Behaviour of WC/Co Hard Metals, Int. J. Refract Metal. Hard. Mater., 2009, 27, p 1–8.

S.I. Baik, E.G. Choi, J.H. Jun et al., Defect Structure Induced by Iron Injection in WC-Co, Scripta Mater., 2008, 58, p 614–617.

H. Abderrazak, F. Schoenstein, M. Abdellaoui and N. Jouini, Spark Plasma Sintering Consolidation of Nanostructured TiC Prepared by Mechanical Alloying, Int. J. Refract. Metal Hard Mater., 2011, 29(2), p 170–176.

Y. Kang and S. Kang, WC-Reinforced (Ti, W)(CN), J. Eur. Ceram. Soc., 2010, 30(3), p 793–798.

H. Wang, D. Yang, X. Zhao et al., Microstructure and Bend Strength of WC-Co and Steel Joints, Sci. Technol. Weld. Joining, 2005, 10, p 167–168.

C. Barbatti, J. Garcia, G. Liedl et al., Joining of Cemented Carbides to Steel by Laser Beam Welding, Materialwissenschaft und Werkstofftechnik: Entwicklung, Fertigung, Prüfung, Eigenschaften und An wendungen technischer Werkstoffe, 2007, 38(11), p 907–914.

L. Zhu, L. Luo, J. Luo et al., Effect of Electroless Plating Ni-Cu-P Layer on Brazability of Cemented Carbide to Steel, Surf. Coat. Technol., 2011, 206(8), p 2521–2524.

W.B. Lee, B.D. Kwon and S.B. Jung, Effect of Bonding Time on Joint Properties of Vacuum Brazed WC-Co Hard Metal/Carbon Steel Using Stacked Cu and Ni Alloy as Insert Metal, Mater. Sci. Technol., 2004, 20(11), p 1474–1478.

G. Chen, R.Q. Deng, W. Xue et al., Research Progress of Cemented Carbide and Steel Welding, Mater. Guide, 2022, 22, p 1–15.

L.B. Ma and J.L. Wang, Analysis of Cemented Carbide Brazing Process, Metall. Mater., 2021, 41(01), p 185–186.

J.J. Zhang, Research Progress and Prospect of Cemented Carbide Brazing Technology, Inform. Record. Mater., 2019, 20(03), p 11–12.

H. Klaasen, J. Kübarsepp, A. Laansoo et al., Reliability of Dual Compounds “Carbide Composite+Steel” Produced by Diffusion welding, Int. J. Refract. Metal. Hard Mater., 2010, 28(5), p 580–586.

M.I. Barrena, J.M. Gomez de Salazar and L. Matesanz, Interfacial and Mechanical Strength of WC-Co/90MnCrV8 Cold Work Tool Steel Diffusion Bonded Joint with Cu/Ni Electroplated Interlayer, Mater. Design, 2010, 31, p 3389–3394.

Y. Zhou, W.F. Gale and T.H. North, Modelling of Transient Liquid Phase Bonding, Metall. Rev., 1995, 40(5), p 181–196.

A. Sadeghian, S.E. Mirsalehi, F. Arhami, A. Malekan, N. Saito and K. Nakashima, Effect of Bonding Time on Dissimilar Transient Liquid Phase (TLP) Bonding of IN939 to IN625 Superalloys: Microstructural Characterization and Mechanical Properties, Metall. Mater. Transact. A, 2021, 52(4), p 1526–1539. https://doi.org/10.1007/s11661-021-06176-x

J.F. Silvain, L. Constantin, J.M. Heintz et al., Controlling Interfacial Exchanges in Liquid Phase Bonding Enables Formation of Strong and Reliable Cu–Sn Soldering for High-Power and Temperature Applications, ACS Appl. Electron. Mater., 2021, 3(2), p 921–928.

H. Assadi, A.A. Shirzadi and E.R. Wallach, Transient liquid phase diffusion bonding under a temperature gradient: modelling of the interface morphology, Acta Mater., 2001, 49(1), p 31–39.

M.L. Shalz, B.J. Dalgleish, A.P. Tomsia et al., Ceramic joining II Partial Transient Liquid-Phase Bonding of Alumina via Cu/Ni/Cu Multilayer Interlayers, J. Mater. Sci., 1994, 29(12), p 3200–3208.

W.F. Gale and Y. Guan, Microstructural Development in Copper-Interlayer Transient Liquid Phase Bonds between Martensitic NiAl and NiTi, J. Mater. Sci., 1997, 32(2), p 357–364.

J.C. Yan, Z.W. Xu, G.H. Wu et al., Interface Structure and Mechanical Performance of TLP Bonded Joints of Al2O3P/6061Al Composites Using Cu/Ni Composite Interlayers, Scripta Mater., 2004, 51(2), p 147–150.

J.M. Gómez De Salazar, F.J. Méndez, A. Ureña, J.M. Guilemany and B.G. Mellor, Transient Liquid Phase (TLP) Diffusion Bonding of a Copper Based Shape Memory Alloy Using Silver as Interlayer, Scripta Mater., 1997, 37(6), p 861–867. https://doi.org/10.1016/S1359-6462(97)00182-6

K. Ohsasa, T. Shinmura and T. Narita, Numerical Modeling of the Transient Liquid Phase Bonding Process of Ni using Ni-B-Cr Ternary Filler Metal, J. Phase Equilibria, 1999, 20(3), p 199–206.

A.A. Shirzadia and E.R. Wallach, Analytical Modelling of Transient Liquid Phase(TLP) Diffusion Bonding when Atemperature Gradient is Imposed[J], Acta Mater., 1999, 47(13), p 3551–3560.

X.G. Wang, X.G. Li and C.G. Wang, Transient Liquid Phase Bonding of Aluminium Alloy using Two-Step Heating Process, Sci. Technol. Weld. Joining, 2012, 17(5), p 414–418.

L. Wang and J.R. Yu, Microstructure and Mechanical Properties of X70 Pipeline Steel Welded Joint by Transient Liquid Phase Diffusion, Electric Welder, 2015, 45(7), p 107–109.

Fracture morphology: the science of observing, measuring and analyzing fracture surface morphology [M]. Translated by Li Xiaogang et al. Beijing: Science press, 2009: 221–241.

F. Guo and Z. Li, Relationship between Fracture Toughness and Microstructure and Properties of Steel, Fail. Anal. Prevent., 2007, 2(4), p 59–64.

X. Zhang, G. Liu, J. Tao et al., Brazing of WC–8Co Cemented Carbide to Steel Using Cu-Ni-Al alloys as Filler Metal: Microstructures and Joint Mechanical Behavior, J. Mater. Sci. Technol., 2018, 34(7), p 1180–1188.

W.B. Lee, B.D. Kwon and S.B. Jung, Effect of Bonding Time on Joint Properties of Vacuum Brazed WC–Co Hard Metal/Carbon Steel Using Stacked Cu and Ni Alloy as Insert Metal, Mater. Sci. Technol., 2004, 20(11), p 1474–1478.

C. Jiang, H. Chen, X. Zhao et al., Microstructure and Mechanical Properties of Brazing Bonded WC-15Co/35CrMo Joint using AgNi/CuZn/AgNi Composite Interlayers, Int. J. Refract Metal. Hard Mater., 2018, 70, p 1–8.

C.T. Kwok, S.L. Fong, F.T. Cheng and H.C. Man, Pitting and Galvanic Corrosion Behavior of Laser-Welded Stainless Steels, J Mater. Process Technol., 2006, 176(1–3), p 168–178.

T.G. Gooch, Corrosion behavior of Welded Stainless Steel, Weld. J. Include. Weld Res. Suppl, 1996, 75(5), p 135–154.

M.A. Ibrahim, S.A. El Rehim and M.M. Hamza, Corrosion Behavior of Some Austenitic Stainless Steels in Chloride Environments, Mater. Chem. Phys., 2009, 115(1), p 80–85.

Z.F. Yin, W.Z. Zhao, W.Y. Lai et al., Electrochemical Behaviour of Ni-base Alloys Exposed Under Oil/Gas Field Environments, Corros. Sci., 2009, 51(8), p 1702–1706.

K. Asami and M. Kikuchi, In-Depth Distribution of Rust on a Plain Carbon steel and Weathering Steels Exposed to Coastal-Industrial Atmosphere for 17 years, Corros. Sci., 2003, 45(11), p 2671–2688.

Brandes E A. Smithells Metals Reference Book: Seventh Edition[J]. 1982.

Funding

This research was supported by National Natural Science Foundation of China (No.51704255).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the author(s).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, B., Chen, J., Zhang, L. et al. Effect of Weld Temperature on Microstructure and Properties of TM52/Q235 Transient Liquid Phase Diffusion-Bonded Joint. J. of Materi Eng and Perform 32, 7456–7467 (2023). https://doi.org/10.1007/s11665-022-07615-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07615-5