Abstract

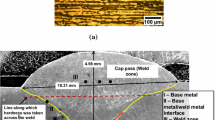

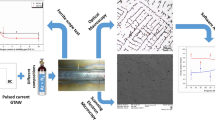

Duplex stainless steel possesses excellent performances when the austenite/ferrite phase ratio is close to 1:1. In this study, a double-layered shielding gas welding method was employed to compare the welding efficiencies and the weld microstructures of the ASTM A240 duplex stainless steel under different shielding gas conditions. The experimental results showed that the welding efficiencies could be improved effectively by adding a small amount of active gas in the shielding gas. The addition of nitrogen in the shielding gas could greatly increase the amount of the austenite phase, and thus a recovery of the austenite/ferrite phase ratio in the weld was achieved. The effects of the solution treatment temperature and the time on the weld microstructures were also studied by using different solution treatment conditions. The results showed that proper solution treatment could improve the austenite phase proportion in the ASTM A240 duplex stainless steel welds. With the increase in the solution temperature and the time, the austenite content was raised obviously, the grain became fine, and the two phases tended to be uniformly distributed.

Similar content being viewed by others

References

H.B. Cui, G.M. Xie, Z.A. Luo, J. Ma, G.D. Wang and R.D.K. Misra, Microstructural Evolution and Mechanical Properties of the Stir Zone in Friction Stir Processed AISI201 Stainless Steel, Material & Design, 2016, 106, p 463–475. https://doi.org/10.1016/j.matdes.2016.05.106

J.C. Lacerda, L.C. Candido and L.B. Godefroid, Effect of Volume Fraction of Phases and Precipitates on the Mechanical Behavior of UNS S31803 Duplex Stainless Steel, Inter. J. Fatigue, 2015, 74, p 81–87. https://doi.org/10.1016/j.ijfatigue.2014.12.015

B. Raj, V. Shankar and A.K. Bhaduri, Welding Technology for Engineers, Alpha Science International, USA, 2006.

R. Badji, M. Bouabdallah, B. Bacroix, C. Kahloun, B. Belkessa and H. Maza, Phase Transformation and Mechanical Behavior in Annealed 2205 Duplex Stainless Steel Welds, Mater. Charact., 2008, 59(4), p 447–453. https://doi.org/10.1016/j.matchar.2007.03.004

T.H. Chen and J.R. Yang, Effects of Solution Treatment and Continuous Cooling on σ-phase Precipitation in a 2205 Duplex Stainless Steel, Mater. Sci. Eng., A, 2001, 311(1–2), p 28–41. https://doi.org/10.1016/S0921-5093(01)00911-X

H. Fujii, T. Sato, S. Lu and K. Nogi, Development of an Advanced A-TIG (AA-TIG) Welding Method by Control of Marangoni Convection, Mater. Sci. Eng., A, 2008, 495(1–2), p 296–303. https://doi.org/10.1016/j.msea.2007.10.116

S. Lu, H. Fujii and K. Nogi, Sensitivity of Marangoni Convection and Weld Shape Variations to Welding Parameters in O2-Ar Shielded GTA Welding, Scripta Materialia, 2004, 51(3), p 271–277. https://doi.org/10.1016/j.scriptamat.2004.03.004

Y. Zou, R. Ueji and H. Fujii, Effect of Oxygen on Weld Shape and Crystallographic Orientation of Duplex Stainless Steel Weld Using Advanced A-TIG (AA-TIG) Welding Method, Mater. Charact., 2014, 91, p 42–49. https://doi.org/10.1016/j.matchar.2014.02.006

P. Roguin, Improved Weld Microstructure in Welding Austenitic-Ferritic Stainless Steels, Weld. Int., 1998, 12(6), p 461–467. https://doi.org/10.1080/09507119809448515

Z. Zhang, H. Jing, L. Xu, Y. Han, L. Zhao and C. Zhou, Effects of Nitrogen in Shielding Gas on Microstructure Evolution and Localized Corrosion Behavior of Duplex Stainless Steel Welding joint, Appl. Surf. Sci., 2017, 404, p 110–128. https://doi.org/10.1016/j.apsusc.2017.01.252

P. Sathiya, S. Aravindan, R. Soundararajan and A.N. Haq, Effect of Shielding Gases on Mechanical and Metallurgical Properties of Duplex Stainless-Steel Welds, J. Mater. Sci., 2009, 44(1), p 114–121. https://doi.org/10.1007/s10853-008-3098-8

V.A. Hosseini, S. Wessman, K. Hurtig and L. Karlsson, Nitrogen Loss and Effects on Microstructure in Multipass TIG Welding of a Super Duplex Stainless Steel, Material & Design, 2016, 98, p 88–97. https://doi.org/10.1016/j.matdes.2016.03.011

V.A. Hosseini and L. Karlsson, Physical and Kinetic Simulation of Nitrogen Loss in High Temperature Heat Affected Zone of Duplex Stainless Steels, Materialia, 2019, 6, 100325. https://doi.org/10.1016/j.mtla.2019.100325

J.O. Nilsson, P. Kangas, A. Wilson and T. Karlsson, Mechanical Properties, Microstructural Stability and Kinetics of σ-Phase Formation in 29Cr-6Ni-2Mo-0.38N Super duplex Stainless Steel, Metall. Mater. Trans. A, 2000, 31, p 35–45. https://doi.org/10.1007/s11661-000-0050-1

R. Badji, M. Bouabdallah, B. Bacroix, C. Kahloun, K. Bettahar and N. Kherrouba, Effect of Solution Treatment Temperature on the Precipitation Kinetic of -phase in 2205 Duplex Stainless Steel Welds, Mater. Sci. Eng., A, 2008, 496(1–2), p 447–454. https://doi.org/10.1016/j.msea.2008.06.024

V. Muthupandi, P.B. Srinivasan, V. Shankar, S.K. Seshadri and S. Sundaresan, Effect of Nickel and Nitrogen Addition on the Microstructure and Mechanical Properties of Power Beam Processed Duplex Stainless Steel (UNS 31803) Weld Metals, Mater. Lett., 2005, 59(18), p 2305–2309. https://doi.org/10.1016/j.matlet.2005.03.010

A.V. Jebaraj, L. Ajaykumar, C.R. Deepak and K. Aditya, Weldability, Machinability and Surfacing of Commercial Duplex Stainless Steel AISI 2205 for Marine Applications-A Recent Review, J. Adv. Res., 2017, 8(3), p 183–199. https://doi.org/10.1016/j.jare.2017.01.002

M.A. Valiente, L. Bermejo, L.E. Karlsson, K. Svensson, H. Hurtig, M. Rasmuson and P. Frodigh, Bengtsson, Effect of Shielding gas on Welding Performance and Properties of Duplex and Superduplex Stainless Steel Welds, Welding in the World, 2015, 59, p 239–249. https://doi.org/10.1007/s40194-014-0199-7

O.E. Falodun, E.B. Mtsweni, S.R. Oke and P.A. Olubambi, Influence of Solution Heat Treatment on Microstructure and Mechanical Properties of a Hot-rolled 2205 Duplex Stainless Steel, J. Mater. Eng. Perform., 2021, 30(10), p 7185–7194. https://doi.org/10.1007/s11665-021-05904-z

M. Ou, Y. Ma, X. Hao, B. Wan, T. Liang and K. Liu, Effect of Solution Annealing on Microstructure and Mechanical Properties of a Ni-Cr-W-Fe Alloy, J. Mater. Sci. Technol., 2017, 33(11), p 1300–1307. https://doi.org/10.1016/j.jmst.2016.06.026

Y.H. Yang, B. Yan, J. Wang and J.L. Yin, The Influence of Solution Treatment Temperature on Microstructure and Corrosion Behavior of High Temperature Ageing in 25% Cr Duplex Stainless Steel, J. Alloy. Compd., 2011, 509(36), p 8870–8879. https://doi.org/10.1016/j.jallcom.2011.06.099

C. Meena and V. Uthaisangsuk, Micromechanics based Modeling of Effect of Sigma Phase on Mechanical and Failure Behavior of Duplex Stainless Steel, Metall. and Mater. Trans. A., 2021, 52(4), p 1293–1313. https://doi.org/10.1007/s11661-021-06163-2

Acknowledgments

This work was supported by the Natural Science Foundation of Jiangsu Province, China (BK20180707).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zou, Y., Zhou, X. Effects of Nitrogen-Added Double Shielding Gas and Solution Treatment on Duplex Stainless Steel Weld Microstructure of Deep-Penetration Tungsten Inert Gas Welding. J. of Materi Eng and Perform 32, 6995–7003 (2023). https://doi.org/10.1007/s11665-022-07594-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07594-7