Abstract

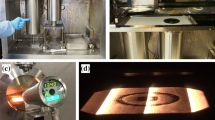

Laser powder bed fusion (LPBF) has unique metal processing characteristics that allow rapid heating and melting of metal powder to form the 3D objects in a layer-by-layer manner. The parts fabricated through LPBF inherited anisotropy behaviors in microstructure and mechanical performance. To effectively ensure the as-built part functionality in terms of microstructure and mechanical performance, scanning direction (SD), building direction (BD), and transverse direction (TD) were selected to be analyzed to build a quantitative process-quality model to control the tensile strength in this study. The influence of hatch distance on microstructure evolution is also investigated. X-ray diffraction (XRD) analysis indicated that (200) peak intensity of γ austenite (fcc) drop-down with hatch distance increased from 0.06 mm to 0.10 mm. Broadening of remelting zone of two adjacent tracks improved the epitaxial growth of column grain. The different ratios of tensile strength and elongation between scanning direction and building direction are 9.23, 19.26% with hatch distance of 0.06 mm, dropped to 3.27, 10.31% with hatch distance of 0.10 mm, respectively. When the hatch distance is over 0.1 mm, the tensile strength and elongation of TD samples drop sharply due to the lack of overlap between molten pools. The different ratio of mechanical anisotropy decreases with hatch distance increases, which also demonstrates that hatch distance can alter the anisotropic of LPBF-ed parts.

Similar content being viewed by others

References

X. Xiao and S. Joshi, Automatic Toolpath Generation for Heterogeneous Objects Manufactured by Directed Energy Deposition Additive Manufacturing Process, J. Manuf. Sci. Eng., 2018, 140, 071005.

X. Xiao, C. Waddell, C. Hamilton, and H. Xiao, Quality Prediction and Control in Wire Arc Additive Manufacturing via Novel Machine Learning, Framework, 2022, 13, p 137.

F. Bosio, A. Aversa, M. Lorusso, S. Marola, D. Gianoglio, L. Battezzati, P. Fino, D. Manfredi, and M. Lombardi, A Time-Saving and Cost-Effective Method to Process Alloys by Laser Powder Bed Fusion, Mater. Des., 2019, 181, 107949.

J.H. Yi, J.W. Kang, T.J. Wang, X. Wang, Y.Y. Hu, T. Feng, Y.L. Feng, and P.Y. Wu, Effect of Laser Energy Density on the Microstructure, Mechanical Properties, and Deformation of Inconel 718 Samples Fabricated by Selective Laser Melting, J. Alloys Compd., 2019, 786, p 481–488.

W. Shi, P. Wang, Y. Liu, Y. Hou, and G. Han, Properties of 316L formed by a 400W power laser Selective Laser Melting with 250μm layer thickness, Powder Technol., 2020, 360, p 151–164.

J. Zhang, Y. Liu, M. Bayat, Q. Tan, Y. Yin, Z. Fan, S. Liu, J.H. Hattel, M. Dargusch, and M.-X. Zhang, Achieving High Ductility in a Selectively Laser Melted Commercial Pure-Titanium via In-Situ Grain Refinem- Ent, Scr. Mater., 2021, 191, p 155–160.

L. Zai, C. Zhang, Y. Wang, W. Guo, D. Wellmann, X. Tong, and Y. Tian, Laser Powder Bed Fusion of Precipitation-Hardened Martensitic Stainless Steels: A Review, Metals., 2020, 10, p 255.

W. Jin, C. Zhang, S. Jin, Y. Tian, D. Wellmann, and W. Liu, Wire Arc Additive Manufacturing of Stainless Steels: A Review, Appl. Sci., 2020, 10, p 1563.

L. Zhou, T. Yuan, R. Li, J. Tang, M. Wang, and F. Mei, Anisotropic Mechanical Behavior of Biomedical Ti-13Nb-13Zr Alloy Manufactured by Selective Laser Melting, J. Alloys Compd., 2018, 762, p 289–300.

S.Y. Liu, H.Q. Li, C.X. Qin, R. Zong, and X.Y. Fang, The Effect of Energy Density on Texture and Mechanical Anisotropy in Selective Laser Melted Inconel 718, Mater. Des., 2020, 191, 108642.

D. Gu and H. Chen, Selective laser melting of high strength and toughness stainless steel parts: The roles of laser hatch style and part placement strategy, Mater. Sci. Eng. A, 2018, 725, p 419–427.

J.J. Marattukalam, D. Karlsson, V. Pacheco, P. Beran, U. Wiklund, U. Jansson, B. Hjörvarsson, and M. Sahlberg, The Effect of Laser Scanning Strategies on Texture, Mechanical Properties, and site-Specific Grain Orientation in Selective Laser Melted 316L SS, Mater. Des., 2020, 193, 108852.

J.J. Yang, H.C. Yu, Z.M. Wang, and X.Y. Zeng, Effect of Crystallographic Orientation on Mechanical Anisotropy of Selective Laser Melted Ti-6Al-4V Alloy, Mater. Charact., 2017, 127, p 137–145.

H. Yu, J. Yang, J. Yin, Z. Wang, and X. Zeng, Comparison on Mechanical Anisotropies of Selective Laser Melted Ti-6Al-4V Alloy and 304 Stainless Steel, Mater. Sci. Eng. A, 2017, 695, p 92–100.

Q. Liu, G. Wang, and C. Qiu, On the Role of Dynamic Grain Movement in Deformation and Mechanical Anisotropy Development in a Selectively Laser Melted Stainless Steel, Addit. Manuf., 2020, 35, 101329.

R. Casati, J. Lemke, and M. Vedani, Microstructure and Fracture Behavior of 316L Austenitic Stainless Steel Produced by Selective Laser Melting, J. Mater. Sci. Technol., 2016, 32, p 738–744.

M.W. Wu, P.H. Lai, and J.K. Chen, Anisotropy in the Impact Toughness of Selective Laser Melted Ti-6Al-4V Alloy, Mater. Sci. Eng., 2016, 650, p 295–299.

C. Qiu, N.J.E. Adkins, and M.M. Attallah, Selective Laser Melting of Invar 36: Microstructure and Properties, Acta Mater., 2016, 103, p 382–395.

R. Rashid, S.H. Masood, D. Ruan, S. Palanisamy, R.A.R. Rashid, J. Elambasseril, and M. Brandt, Effect of Energy Per Layer on the Anisotropy of Selective Laser Melted AlSi12 Aluminium Alloy, Addit. Manuf., 2018, 22, p 426–439.

M. Bahshwan, C.W. Myant, T. Reddyhoff, and M.-S. Pham, The Role of Microstructure on Wear Mechanisms and Anisotropy of Additively Manufactured 316L Stainless Steel in Dry Sliding, Mater. Des., 2020, 196, 109076.

Y. Yang, Y. Zhu, M.M. Khonsari, and H. Yang, Wear Anisotropy of Selective Laser Melted 316L Stainless Steel, Wear, 2019, 428–429, p 376–386.

K. Lin, D. Gu, L. Xi, L. Yuan, S. Niu, P. Lv, and Q. Ge, Selective Laser Melting Processing of 316L Stainless Steel: Effect of Microstructural Differences Along Building Direction on Corrosion Behavior, Int J Adv Manuf Technol., 2019, 104, p 2669–2679.

F. Stern, J. Kleinhorst, J. Tenkamp, and F. Walther, Investigation of the Anisotropic Cyclic Damage Behavior of Selective Laser Melted AISI 316L Stainless Steel, Fatigue Fract. Eng. Mater. Struct., 2019, 42, p 2422–2430.

S. Wen, S. Li, Q. Wei, Y. Chunze, S. Zhang, and Y. Shi, Effect of Molten Pool Boundaries on the Mechanical Properties of Selective Laser Melting Parts, J. Mater. Process. Technol., 2014, 214, p 2660–2667.

S. Jyoti and K.G.U. PrashanthRamamurty, Mechanical Behavior of Selective Laser Melted 316L Stainless Steel, Mater. Sci. Eng., 2017, 696, p 113–121.

D. Dai, D. Gu, H. Zhang, J. Xiong, C. Ma, C. Hong, and R. Poprawe, Influence of Scan Strategy and Molten Pool Configuration on Microstructures and Tensile Properties of Selective Laser Melting Additive Manufactured Aluminum Based Parts, Opt. Laser Technol., 2018, 99, p 91–100.

T. Niendorf, S. Leuders, A. Riemer, H.A. Richard, T. Troster, and D. Schwarze, Highly Anisotropic Steel Processed by Selective Laser Melting, Metall Mater Trans B., 2013, 44, p 794–796.

D.C. Kong, X.Q. Ni, C.F. Dong, L. Zhang, C. Man, X.Q. Cheng, and X.G. Li, Anisotropy in the Microstructure and Mechanical Property for the Bulk and Porous 316L Stainless Steel Fabricated via Selective Laser Melting, Mater. Lett., 2019, 235, p 1–5.

J. Suryawanshi, K.G. Prashanth, and U. Ramamurty, Mechanical Behavior of Selective Laser Melted 316L Stainless Steel, Mater. Sci. Eng., 2017, 696, p 113–121.

Z. Sun, X. Tan, S.B. Tor, and W.Y. Yeong, Selective Laser Melting of Stainless Steel 316L with Low Porosity and High Build Rates, Mater. Des., 2016, 104, p 197–204.

J.A. Cherry, H.M. Davies, S. Mehmood, N.P. Lavery, S.G.R. Brown, and J. Sienz, Investigation into the Effect of Process Parameters on Microstructural and Physical Properties of 316L Stainless Steel Parts by Selective Laser Melting, Int J Adv Manuf Technol., 2015, 76, p 869–879.

J. Hou, W. Chen, Z. Chen, K. Zhang, and A. Huang, Microstructure, Tensile Properties and Mechanical Anisotropy of Selective Laser Melted 304L Stainless Steel, J. Mater. Sci. Technol., 2020, 48, p 63–71.

Y. Zhong, L. Liu, S. Wikman, D. Cui, and Z. Shen, Intragranular Cellular Segregation Network Structure Strengthening 316L Stainless Steel Prepared by Selective Laser Melting, J. Nucl. Mater., 2016, 470, p 170–178.

K.A. Sofinowski, S. Raman, X. Wang, B. Gaskey, and M. Seita, Layer-Wise Engineering of Grain Orientation (LEGO) in Laser Powder Bed Fusion of Stainless Steel 316L, Addit. Manuf., 2021, 38, 101809.

O.O. Salman, F. Brenne, T. Niendorf, J. Eckert, K.G. Prashanth, T. He, and S. Scudino, Impact of the Scanning Strategy on the Mechanical Behavior of 316L Steel Synthesized by Selective Laser Melting, J. Manuf. Processes., 2019, 45, p 255–261.

D. Kong, C. Dong, X. Ni, L. Zhang, J. Yao, C. Man, X. Cheng, K. Xiao, and X. Li, Mechanical Properties and Corrosion Behavior of Selective Laser Melted 316L Stainless Steel After Different Heat Treatment Processes, J. Mater. Sci. Technol., 2019, 35, p 1499–1507.

Z. Zhang, B. Chu, L. Wang, and Z. Lu, Comprehensive Effects of Placement Orientation and Scanning Angle on Mechanical Properties and Behavior of 316L Stainless Steel Based on the Selective Laser Melting Process, J. Alloys Compd., 2019, 791, p 166–175.

Acknowledgments

This paper is funded by “Special project for the central government to guide local scientific and Technological Development of Hebei province” (Project Number: 226Z1903G) and “National Natural Science Foundation of China” (Project Number: 61802108).

Author information

Authors and Affiliations

Contributions

ZZ: Investigation, Data curation, Methodology. SW: Writing—original draft, Data curation, Methodology. HL: Writing—reviewing & editing. LW: Methodology, Writing—reviewing & editing. XX: Writing—reviewing & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Z., Wang, S., Liu, H. et al. Effects of Hatch Distance on the Microstructure and Mechanical Anisotropy of 316 L Stainless Steel Fabricated by Laser Powder Bed Fusion. J. of Materi Eng and Perform 32, 4757–4767 (2023). https://doi.org/10.1007/s11665-022-07416-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07416-w