Abstract

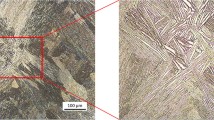

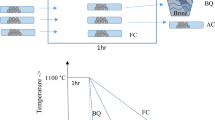

The high-temperature deformation behavior of Ti-6.5Al-2Sn-4Zr-4Mo-1W-0.2Si alloy with lamellar starting structure was investigated by carrying a series of isothermal compression tests at temperatures of 850-1030 °C and strain rates of 0.001-10 s−1 on the Gleeble-3500 simulator. Strain-rate sensitivity exponent and deformation activation energy have been analyzed associated with the dynamic softening behaviors. Meanwhile, different identification approaches like power dissipation distribution and work-hardening derivative have been adopted to identify the softening behaviors corresponding to different deformation parameters. Then constitutive models based on the dislocation evolution have been employed to characterize the flow curves of Ti-6.5Al-2Sn-4Zr-4Mo-1W-0.2Si alloy. Finally, microstructure observation has been carried out to verify the dynamic softening behaviors occurred under different deformation conditions.

Similar content being viewed by others

References

X.M. Yang, Z.L. Zhao, Y.Q. Ning, H.Z. Guo, H. Li, S.C. Yuan, and S.W. Xin, Microstructural Evolution and Mechanical Property of Isothermally Forged BT25y Titanium Alloy with Different Double-Annealing Processes, Mater. Sci. Eng. A, 2019, 745, p 240–251.

Y. Nan, Y.Q. Ning, H.Q. Liang, H.Z. Guo, Z.K. Yao, and M.W. Fu, Work-Hardening Effect and Strain-Rate Sensitivity Behavior During Hot Deformation of Ti-5Al-5Mo-5V-1Cr-1Fe Alloy, Mater. Des., 2015, 82, p 84–90.

E. Ghasemi, A. Zarei-Hanzaki, E. Farabi, K. Tesar, A. Jager, and M. Rezaee, Flow Softening and Dynamic Recrystallization Behavior of BT9 Titanium Alloy: A Study Using Process Map Development, J. Alloys Compd., 2017, 695, p 1706–1718.

L.X. Ma, M. Wan, W.D. Li, J. Shao, and X.P. Bai, Constitutive Modeling and Processing Map for Hot Deformation of Ti-15Mo-3Al-2.7Nb-0.2Si, J. Alloys Compd., 2019, 808, p 151759.

G.Z. Quan, G.C. Luo, J.T. Liang, D.S. Wu, A. Mao, and Q. Liu, Modelling for the Dynamic Recrystallization Evolution of Ti-6Al-4V Alloy in Two-Phase Temperature Range and A Wide Strain Rate Range, Comput. Mater. Sci., 2015, 97, p 136–147.

K. Tan, J. Li, Z.J. Guan, J.B. Yang, and J.X. Shu, The Identification of Dynamic Recrystallization and Constitutive Modeling During Hot Deformation of Ti55511 Titanium Alloy, Mater. Des., 2015, 84, p 204–211.

Y.Q. Jiang, Y.C. Lin, G.Q. Wang, G.D. Pang, M.S. Chen, and Z.C. Huang, Microstructure Evolution and A Unified Constitutive Model for A Ti-55511 Alloy Deformed in β Region, J. Alloys Compd., 2021, 870, p 159534.

Y.C. Lin, Y.W. Xiao, Y.Q. Jiang, G.D. Pang, H.B. Li, X.Y. Zhang, and K.C. Zhou, Spheroidization and Dynamic Recrystallization Mechanisms of Ti-55511 Alloy with Bimodal Microstructures During Hot Compression in α+β Region, Mater. Sci. Eng. A, 2020, 782, p 139282.

G.D. Pang, Y.C. Lin, Y.L. Qiu, Y.Q. Jiang, Y.W. Xiao, and M.S. Chen, Dislocation Density-Based Model and Stacked Auto-Encoder Model for Ti-55511 Alloy with Basket-Weave Microstructures Deformed in α+β Region, Adv. Eng. Mater., 2021, 23, p 2001307.

G. Su, Z. Yun, Y.C. Lin, D.G. He, S. Zhang, and Z.J. Chen, Microstructure Evolution and A Unified Constitutive Model of Ti-55511 Alloy Compressed at Stepped Strain Rates, Materials, 2021, 14, p 6750.

N. Haghdadi, A. Zarei-Hanzaki, and H.R. Abedi, The Flow Behavior Modeling of Cast A356 Aluminum Alloy at Elevated Temperatures Considering the Effect of Strain, Mater. Sci. Eng. A, 2012, 535, p 252–257.

J. Luo, L.F. Wang, S.F. Liu, and M.Q. Li, The Correlation Between the Flow Behavior and the Microstructure Evolution During Hot Working of TC18 Alloy, Mater. Sci. Eng. A, 2016, 654, p 213–220.

L.X. Ma, M. Wan, W.D. Li, J. Shao, X.N. Han, and J.C. Zhang, On the Superplastic Deformation Mechanisms of Near-α TNW700 Titanium Alloy, J. Mater. Sci. Technol., 2022, 108, p 173–185.

C. Cheng, Z. Chen, H.E. Li, X. Wang, S. Zhu, and Q. Wang, Vacuum Superplastic Deformation Behavior of A Near-α Titanium Alloy TA32 Sheet, Mater. Sci. Eng. A, 2021, 800, p 140362.

Y.G. Zhou, W.D. Zeng, X.Q. Li, H.Q. Yu, and C.X. Cao, An Investigation of High-Temperature Deformation Strengthening and Toughening Mechanism of Titanium Alloy, Acta Metall. Sin., 1999, 35(1), p 45–48.

E.I. Galindo-Nava and P.E.J. Rivera-Dıaz-del-Castillo, A Thermostatistical Theory of Low and High Temperature Deformation in Metals, Mater. Sci. Eng. A, 2012, 543, p 110–116.

C.J. Shi, W.M. Mao, and X.G. Chen, Evolution of Activation Energy During Hot Deformation of AA7150 Aluminum Alloy, Mater. Sci. Eng. A, 2013, 571, p 83–91.

D. Caillard and J.L. Martin, Thermally activated mechanisms in crystal plasticity, Pergamon Press, Oxford, 2003.

X.J. Lin, H.J. Huang, X.G. Yuan, Y.X. Wang, B.W. Zheng, X.J. Zuo, and G. Zhou, Establishment and Validity Verification of the Hot Processing Map of a Ti-47.5Al-2.5V-1.0Cr-0.2Zr Alloy with A Lamellar Microstructure, Mater. Charact., 2022, 183, p 111599.

C.M. Li, L. Huang, M.J. Zhao, S.Q. Guo, Y. Su, and J.J. Li, Characterization of Hot Workability of Ti-6Cr-5Mo-5V-4Al Alloy Based on Hot Processing Map and Microstructure Evolution, J. Alloys Compd., 2022, 905, p 164161.

Y.Q. Ning, B.C. Xie, H.Q. Liang, H. Li, X.M. Yang, and H.Z. Guo, Dynamic Softening Behavior of TC18 Titanium Alloy During Hot Deformation, Mater. Des., 2015, 71, p 68–77.

F.J. Humphreys and M. Hatherly, Recrystallization and related annealing phenomena, 2nd ed. Elsevier, Oxford, 2004.

E.I. Poliak and J.J. Jonas, A One-Parameter Approach to Determining the Critical Conditions for the Initiation of Dynamic Recrystallization, Acta Mater., 1996, 44, p 127–136.

H. Mecking and U.F. Kocks, Kinetics of Flow and Strain-Hardening, Acta Metall., 1981, 29, p 1865–1875.

Y. Estrin and H. Mecking, A Unified Phenomenological Description of Work Gardening an Creep Based on One-Parameter Models, Acta Metall., 1984, 32(1), p 57–70.

H.W. Li, X.X. Sun, and H. Yang, A Three-Dimensional Cellular Automata-Crystal Plasticity Finite Element Model for Predicting the Multiscale Interaction Among Heterogeneous Deformation, DRX Microstructural Evolution and Mechanical Responses in Titanium Alloys, Int. J. Plast., 2016, 87, p 154–180.

H. Chen, Z. Chen, J. Liu, Y. Wu, C.Y. Dan, S.Y. Zhong, H.W. Wang, and Y. Bréchet, Constitutive Modeling of Flow Stress and Work Hardening Behavior While Considering Dynamic Strain Aging, Materialia, 2021, 18, 101137.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (No. 51904276), the Key Scientific Research Project of Colleges and Universities in Henan Province (No.20A430032) and Key R & D and Promotion Special Project of Henan Province (No.202102210212, 222102220093).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, X., Shi, X., Yan, X. et al. Dynamic Softening Behavior of Ti-6.5Al-2Sn-4Zr-4Mo-1W-0.2Si Alloy with Lamellar Starting Microstructure during Hot Deformation. J. of Materi Eng and Perform 32, 3729–3738 (2023). https://doi.org/10.1007/s11665-022-07337-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07337-8