Abstract

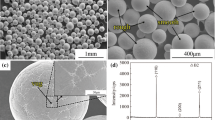

Dense Ti-48Al-2Cr-2Nb-xGd (x = 0, 0.15, 0.3 at. %) alloys with different compositions were prepared by spark plasma sintering (SPS). The phase composition and microstructure of sintered alloys were studied by x-ray diffraction analyzer (XRD), scanning electron microscope (SEM) and transmission electron microscope (TEM). The mechanical properties were determined by room-temperature compression test. Results show that Gd2O3 and Al3Gd are the gadolinium-rich precipitates formed at the boundary of the original powder particles after the addition of Gd. However, with the increase in Gd addition, the precipitates will gather and grow together, and the dispersed fine precipitates play the role of dispersion strengthening, while the large particles gathered together play the opposite role. The TiAl alloy added with 0.15%Gd has the best compressive properties, and the ultimate compressive strength and fracture strain are 2750 MPa and 43.59%, respectively, which are significantly better than the cast alloy and the alloy without Gd.

Similar content being viewed by others

References

C. Shi, K. Zhang, Z. Lu, and H. Xiao, Microstructure Evolution and Mechanical Properties of Ti46.5Al2Cr1.8Nb-(W, B) Alloys Fabricated by Spark Plasma Sintering and Pulse Current Assisted Isothermal forging, Mater, Sci. Eng., A, 2019, 747, p 98-110.

X. Xu, H. Ding, H. Huang, H. Liang, R. Chen, J. Guo, and H. Fu, Microstructure and Elevated Temperature Tensile Property of Ti-46Al-7Nb-(W, Cr, B) Alloy Compared with Binary and Ternary TiAl Alloy, Mater. Sci. Eng. A., 2021, 807, p 153852.

H. Zhou, Y. Su, N. Liu, F. Kong, X. Wang, X. Zhang, and Y. Chen, Modification of Microstructure and Properties of Ti-47Al-2Cr-4Nb-0.3W Alloys Fabricated by SPS with Trace Multilayer Graphene Addition, Mater. Charact., 2018, 138, p 1-10.

A. Couret, T. Voisin, M. Thomas, and J.-P. Monchoux, Development of a TiAl Alloy by Spark Plasma Sintering, JOM, 2017, 69(12), p 2576-2582.

J.M. Liang, L. Cao, Y.H. Xie, Y. Zhou, Y.F. Luo, K.Q. Mudi, H.Y. Gao, and J. Wang, Microstructure and Mechanical Properties of Ti-48Al-2Cr-2Nb Alloy Joints Produced by Transient Liquid Phase Bonding Using Spark Plasma Sintering, Mater. Charact., 2019, 147, p 116-126.

Y. Liu, Y. Pan, X. Lu, J. Sun, T. Hui, Y. Yang, A. Yu, X. Qu, and J. Zhang, Fabrication of TiAl Alloys Turbocharger Turbine Wheel for Engines by Metal Injection Molding, Powder Technol., 2021, 384, p 132-140.

S. Saeedipour and A. Kermanpur, On the Microstructure and Solidification Behavior of N-Bearing Ti-46Al-8Ta (at.%) Intermetallic Alloys, J. Mater. Eng. Perform., 2019, 28(10), p 6438-6448.

H.W. Liu, D.P. Bishop, and K.P. Plucknett, Densification Behaviour and Microstructural Evolution of Ti-48Al Consolidated by Spark Plasma Sintering, J. Mater. Sci., 2017, 52(1), p 613-627.

T. Voisin, J.-P. Monchoux, M. Thomas, C. Deshayes, and A. Couret, Mechanical Properties of the TiAl IRIS Alloy, Metall. Mater. Trans. A, 2016, 47(12), p 6097-6108.

D. Wang, H. Zhao, and W. Zheng, Effect of temperature-related factors on densification, microstructure and mechanical properties of powder metallurgy TiAl-based alloys, Adv. Powder Technol., 2019, 30(11), p 2555-2563.

J. Lapin, M. Štamborská, T. Pelachová, and O. Bajana, Fracture behaviour of cast in-situ TiAl matrix composite reinforced with carbide particles, Mater. Sci. Eng., A, 2018, 721, p 1-7.

D. Wang, D. Sun, X. Han, Q. Wang, N. Zhang, and F. Xu, Fabrication and Mechanical Properties of In Situ Synthesized Ti2AlN/TiAl Composite, J. Mater. Eng. Perform., 2018, 27(8), p 4336-4344.

X. Gu, F. Cao, N. Liu, G. Zhang, D. Yang, H. Shen, D. Zhang, H. Song, and J. Sun, Microstructural Evolution and Mechanical Properties of a High Yttrium Containing TiAl Based alloy Densified by Spark Plasma Sintering, J. Alloy. Compd., 2020, 819, 153264.

H.R. Ghorbani, A. Kermanpur, A. Rezaeian, A. Ahmadi Siahboumi, and M. Ali Taebi, Effect of N Addition on Microstructure and high Temperature Mechanical Properties of Ti-48Al-2Cr-2Nb (at. %) Intermetallic Alloy, Mater. Today Commun., 2020, 25, p 101494.

V. Singh, C. Mondal, R. Sarkar, P.P. Bhattacharjee, and P. Ghosal, Effects of Cr Alloying on the Evolution of Solidification Microstructure and Phase Transformations of High-Nb Containing γ-TiAl Based Alloys, Intermetallics, 2021, 131, 107117.

T. Voisin, J.-P. Monchoux, M. Perrut, and A. Couret, Obtaining of a fine Near-lamellar Microstructure in TiAl alloys by Spark Plasma Sintering, Intermetallics, 2016, 71, p 88-97.

L.L. Zhao, G.Y. Li, L.Q. Zhang, J.P. Lin, X.P. Song, F. Ye, and G.L. Chen, Influence of Y Addition on the Long Time Oxidation Behaviors of high Nb Containing TiAl Alloys at 900 °C, Intermetallics, 2010, 18(8), p 1586-1596.

R. Ding, I.P. Jones, Y. Chiu, and R. Chen, Microstructure and Mechanical Property of Directionally Solidified Ti-46Al-0.5W-0.5Si alloys with and without Gd, Intermetallics, 2012, 20(1), p 123-134.

P.V. Panin, A.S. Kochetkov, A.V. Zavodov, and E.A. Lukina, Effect of Gd Addition on Phase Composition, Structure, and Properties of Beta-solidifying TiAl-based Alloy with Zr and Cr Content Variability, Intermetallics, 2020, 121, p 1900107.

K. Xia, X. Wu, and D. Song, Effects of Gd addition, lamellar spacing and loading direction on creep behaviour of a fully lamellar Ti-44Al-1Mn-2.5Nb alloy, Acta Mater., 2004, 52(4), p 841-849.

D. Zhang, N. Liu, Y. Chen, G. Zhang, J. Tian, F. Kong, S. Xiao, and J. Sun, Microstructure Evolution and Mechanical Properties of PM-Ti43Al9V0.3Y Alloy, Materials, 2020, 13(1), p 198.

H. Sun, Z. Wang, Y. Du, and J. Yuan, Densification Mechanism and Microstructure Evolution of Ti-48Al-2Cr-8Nb Alloy by Spark Plasma Sintering, Cryst. Res. Technol., 2019, 54(11), p 1900107.

Y. Su, Y. Lin, N. Zhang, and D. Zhang, Microstructures and mechanical properties of TiAl alloy fabricated by spark plasma sintering, Int. J. Mod. Phys. B, 2019, 34, p 2040036.

S. Saeedipour, A. Kermanpur, and F. Sadeghi, Effect of N addition on microstructure refinement and high temperature mechanical properties of Ti-46Al-8Ta (at. %) intermetallic alloy, J. Alloy. Compd., 2020, 817, p 152749.

M. Thomas, J.L. Raviart, and F. Popoff, Cast and PM Processing Development in Gamma Aluminides, Intermetallics, 2005, 13(9), p 944-951.

Z. Trzaska, G. Bonnefont, G. Fantozzi, and J.P. Monchoux, Comparison of Densification Kinetics of a TiAl Powder by Spark Plasma Sintering and Hot Pressing, Acta Mater., 2017, 135, p 1-13.

C. Collard, Z. Trzaska, L. Durand, J.-M. Chaix, and J.-P. Monchoux, Theoretical and Experimental Investigations of Local Overheating at Particle Contacts in Spark Plasma Sintering, Powder Technol., 2017, 321, p 458-470.

Y. Wang, C. Zhang, Y. Liu, S. Zhao, and J. Li, Microstructure Characterization and Mechanical Properties of TiAl-based Alloys Prepared by Mechanical Milling and Spark Plasma Sintering, Mater. Charact., 2017, 128, p 75-84.

S.O. Jeje, M.B. Shongwe, N. Maledi, P.A. Olubambi, and B.J. Babalola, Spark Plasma Sintering of Ti-48Al Intermetallic using Elemental Powder, Int. J. Adv. Manuf Tech., 2019, 103(5-8), p 3025-3032.

D. Wang, R. Zhang, H. Yuan, and J. Qiang, Effect of Microstructure on the Hot Deformation Behavior of TiAl-Based Alloys Prepared by Powder Metallurgy Method, JOM, 2017, 69(10), p 1824-1829.

Y. Xia, J.L. Zhao, and M. Qian, Spark Plasma Sintering of Ti-48Al-2Cr-2Nb Alloy Powder and Characterization of an Unexpected Phase, JOM, 2019, 71(8), p 2556-2563.

X. Gu, S. Jiang, F. Cao, G. Zhang, D. Yang, S. Guo, H. Song, and J. Sun, A β-solidifying TiAl alloy reinforced with ultra-fine Y-rich precipitates, Scripta Mater., 2021, 192, p 55-60.

V.S. Sokolovsky, N.D. Stepanov, S.V. Zherebtsov, N.A. Nochovnaya, P.V. Panin, M.A. Zhilyakova, A.A. Popov, and G.A. Salishchev, Hot deformation behavior and processing maps of B and Gd containing β-solidified TiAl based alloy, Intermetallics, 2018, 94, p 138-151.

V.S. Sokolovsky, N.D. Stepanov, S.V. Zherebtsov, E.I. Volokitina, P.V. Panin, N.A. Nochovnaya, S.D. Kaloshkin, and G.A. Salishchev, The effect of Gd addition on the kinetics of α2→γ transformation in γ-TiAl based alloys, Intermetallics, 2020, 120, 106759.

Y. Yang, H. Feng, Q. Wang, R. Chen, J. Guo, H. Ding, and Y. Su, Improvement of microstructure and mechanical properties of TiAl−Nb alloy by adding Fe element, Trans. Nonferrous Met. Soc. China, 2020, 30(5), p 1315-1324.

H. Fang, R. Chen, X. Chen, Z. Ma, H. Ding, and J. Guo, Microstructure and mechanical properties of Ti44Al6Nb alloys with different cerium contents, Rare Met., 2020, 39, p 402-407.

D. Wang, H. Yuan, and J. Qiang, The Microstructure Evolution, Mechanical Properties and Densification Mechanism of TiAl-Based Alloys Prepared by Spark Plasma Sintering, Metals, 2017, 7(6), p 201.

M. Pang, Y. Zhan, M. Ling, S. Wei, Y. Liu, and Y. Du, First-principles Study on the Crystal, Electronic Structure and Mechanical Properties of Hexagonal Al3RE (RE = La, Ce, Pr, Nd, Sm, Gd) Intermetallic Compounds, Solid State Commun., 2011, 151(17), p 1135-1140.

Y.H. Wang, J.P. Lin, Y.H. He, Y.L. Wang, and G.L. Chen, Microstructures and mechanical properties of Ti-45Al-8.5Nb-(WBY) alloy by SPS–HIP route, Mater. Sci. Eng., A, 2008, 489(12), p 55-61.

S. Xiao, Y. Guo, Z. Liang, X. Wang, J. Yang, X. Wang, L. Xu, J. Tian, and Y. Chen, The Effect of Nano-Y2O3 Addition on Tensile Properties and Creep Behavior of as-cast TiAl Alloy, J. Alloy. Compd., 2020, 825, 153852.

Acknowledgements

This research was sponsored by the National Key Research and Development Program of China (No. 2016YFB1200505) and Cultivation project for original scientific research instruments and equipment of Southwest Jiaotong University (NO. XJ2021KJZK041).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guo, Q., Sun, H., Liu, R. et al. Microstructure and Mechanical Properties of TiAl Alloys with Gd Densified by Spark Plasma Sintering. J. of Materi Eng and Perform 32, 1627–1635 (2023). https://doi.org/10.1007/s11665-022-07234-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07234-0