Abstract

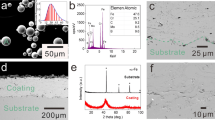

Corrosion of rebar is the key factor affecting the service life of reinforced concrete, and amorphous coatings with superior corrosion resistance can be a potential protective material for the rebar. In the present study, a self-designed arc-sprayed Fe-based amorphous coating deposited on the surface of Q235 steel was investigated. The long-term electrochemical behavior of arc-sprayed Fe-based amorphous coating after pore-sealing treatment was studied for the first time. The microstructure of the sprayed coating was characterized by scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The pores of the coating were sealed using the infiltration method. To explore the electrochemical behavior of the unmodified sprayed coating and the pore-sealed coating, electrochemical tests in 3.5 wt.% NaCl solution were employed. According to the SEM and TEM results, the unmodified sprayed coating was dense with a layered structure and was composed of an amorphous matrix and nanocrystalline structures. The average porosity of the unmodified sprayed coating was 3.95%. Electrochemical experiments revealed that the electrochemical response of the coating was more capacitive after pore-sealing treatment, which resulted in improved corrosion resistance. Kindly check and confirm whether the corresponding author is correctly identified.The identity of the corresponding author is correct.

Similar content being viewed by others

References

M. Harilal, V.R. Rathish, B. Anandkumar et al., High Performance Green Concrete (HPGC) with Improved Strength and Chloride ion Penetration Resistance by Synergistic Action of fly ash, Nanoparticles and Corrosion Inhibitor, Constr. Build. Mater., 2019, 198, p 299–312.

P.K. Mehta, Durability of Concrete–fifty Years of Progress, Special Publication, 1991, 126, p 1–32.

M. Stefanoni, U. Angst, and B. Elsener, Corrosion rate of Carbon Steel in Carbonated Concrete – A Critical Review, Cem. Concr. Res., 2018, 103, p 35–48.

J. Carmona Calero, M.A. Climent Llorca, and P. GarcésTerradillos, Influence of Different Ways of Chloride Contamination on the Efficiency of Cathodic Protection Applied on Structural Reinforced Concrete Elements, J. Electroanal. Chem., 2017, 793, p 8–17.

Y. Liu, Z. Song, W. Wang et al., Effect of Ginger Extract as Green Inhibitor on Chloride-Induced Corrosion of Carbon Steel in Simulated Concrete Pore Solutions, J. Clean. Prod., 2019, 214, p 298–307.

T.A. Tawfik, M.A. El-Yamani, S. Abd El-Aleem et al., Effect of Nano-Silica and Nano-Waste Material on Durability and Corrosion Rate of Steel reinforcement Embedded in High-Performance Concrete, Asian J. Civil Eng., 2019, 20(1), p 135–47.

G. Zhang, Q. Xie, C. Ma et al., Permeable Epoxy Coating with Reactive Solvent for Anticorrosion of Concrete, Prog. Org. Coat., 2018, 117, p 29–34.

G. Qiao, B. Guo, J. Ou et al., Numerical Optimization of an Impressed Current Cathodic Protection System for Reinforced Concrete Structures, Constr. Build. Mater., 2016, 119, p 260–267.

X.H. Wang, and Y. Gao, Corrosion Behavior of Epoxy-Coated Reinforced Bars in RC test Specimens Subjected to Pre-Exposure Loading and Wetting-Drying Cycles, Constr. Build. Mater., 2016, 119, p 185–205.

H. Zheng, J.G. Dai, L. Hou et al., Enhanced Passivation of Galvanized Steel Bars in Nano-Silica Modified Cement Mortars, Cement Concr. Compos., 2020, 111, 103626.

Z. Zeng, L. Wang, A. Liang et al., Tribological and Electrochemical Behavior of thick Cr–C Alloy Coatings Electrodeposited in Trivalent Chromium bath as an Alternative to Conventional Cr Coatings, Electrochim. Acta, 2006, 52(3), p 1366–1373.

T. Liu, Z. Guo, Z. Zeng et al., Marine Bacteria Provide Lasting Anti-Corrosion Activity for Steel via Biofilm-induced Mineralization, ACS Appl. Mater. Interfaces., 2018, 10(46), p 40317–40327.

E.M. Khadijah, and A.I.K. Albandaree, Impact of pH on the Corrosion of Novel Metal-Metal Glassy Alloys in Artificial Seawater: An Electrochemical and Morphology Study, J. Mater. Eng. Perform., 2020, 29(1), p 175–181.

A. Takeuchi, and A. Inoue, Classification of Bulk Metallic Glasses by Atomic size Difference, Heat of Mixing and Period of Constituent Elements and its Application to Characterization of the main Alloying Element, Mater. Trans., 2005, 46(12), p 2817–2829.

Q. Zhang, P. Zhang, H. Yan et al., Magnetic-Field-Assisted Laser Cladding in the Preparation of a CRACK-free Fe-Cr-Mo-C-Y-B Amorphous Coating on Steel, Philos. Mag. Lett., 2020, 100(2), p 86–93.

M. Komaki, T. Mimura, Y. Kusumoto et al., Formation of Fe-Based Amorphous Coating Films by Thermal Spraying Technique, Mater. Trans., 2010, 51(9), p 1581–1585.

C. Jiang, W. Liu, G. Wang et al., The Corrosion Behaviours of Plasma-Sprayed Fe-Based Amorphous Coatings, Surf. Eng., 2018, 34(8), p 1–6.

H.Y. Yuan, H.M. Zhai, W.S. Li et al., Study of Dry Sliding Wear Behavior of a Fe-Based Amorphous Coating Synthesized by Detonation Spraying on an AZ31B Magnesium Alloy[J], J. Mater. Eng. Perform., 2021, 30(2), p 905–917.

E. Sadeghi, and S. Joshi, Chlorine-Induced High-Temperature Corrosion and Erosion-Corrosion of HVAF and HVOF-Sprayed Amorphous Fe-Based coatings, Surf. Coat. Technol., 2019, 371, p 20–35.

H. Tong, S. Wei, Q. Wang et al., Corrosion Mechanism and Behavior of High‐Velocity Arc‐Sprayed Al–Ti–Si–RE Coating in a Simulated Deep sea, Mater. Corrosion, 2019, 71(6), p 1007–1018.

B. Huang, C. Zhang, G. Zhang et al., Wear and Corrosion Resistant Performance of Thermal-SPRAYED Fe-based Amorphous Coatings: A Review, Surf. Coat. Technol., 2019, 377, p 1–12.

J. Zhang, C. Deng, J. Song et al., Electrochemical Corrosive Behaviors of Fe-Based Amorphous/ Nanocrystalline Coating on Stainless Steel Prepared by HVOF-Sprayed, Coatings, 2019, 9(4), p 226.

S.D. Zhang, J. Wu, W.B. Qi et al., Effect of Porosity Defects on the long-Term Corrosion Behaviour of Fe-Based Amorphous alloy Coated Mild Steel, Corros. Sci., 2016, 110, p 57–70.

P. Li, L. Meng, S. Wang et al., In Situ Formation of Ti47Cu38Zr7.5Fe2.5Sn2Si1Nb2 Amorphous Coating by Laser Surface Remelting, Materials, 2019, 12(22), p 1–9.

M.M. Liu, H.X. Hu, Y.G. Zheng, J.Q. Wang, Z.H. Gan, and S. Qiu, Effect Of Sol-Gel Sealing Treatment Loaded with Different Cerium Salts on the Corrosion Resistance of Fe-Based Amorphous Coating, Surf. Coat. Technol., 2019, 367, p 311–326.

M. Liu, H.X. Hu, Y.G. Zheng et al., Effects of Three Sealing Methods of Aluminum Phosphate Sealant on Corrosion Resistance of the Fe-Based Amorphous Coating, Surf. Coat. Technol., 2017, 309, p 579–589.

A. Inoue, Stabilization of Metallic Supercooled Liquid and Bulk Amorphous Alloys, Acta Mater., 2000, 48(1), p 279–306.

W. Guo, J. Zhang, Y. Wu et al., Fabrication and Characterization of Fe-Based Amorphous Coatings Prepared by High-Velocity arc Spraying, Mater. Des., 2015, 78, p 118–124.

D. Wu, Z.S. Fan, and Y. Yang, Formation and Properties of Fe-Based Amorphous/Nanocrystalline Alloy Coating Prepared by Wire Arc Spraying Process, Mater. Ence. Forum., 2019, 944, p 499–505.

W. Guo, Y. Wu, J. Zhang et al., Fabrication and Characterization of Thermal-Sprayed Fe-Based Amorphous/Nanocrystalline Composite Coatings: An Overview, J. Therm. Spray Technol., 2014, 23(7), p 1157–1180.

M. Stern, A Method For Determining Corrosion Rates From Linear Polarization Data, Corrosion, 1958, 14(9), p 60–64.

A. Aliyu, and C. Srivastava, Corrosion Behavior and Protective film Constitution of AlNiCoFeCu and AlCrNiCoFeCu High Entropy Alloy Coatings, Surf. Int., 2021, 27, 101481.

A. Hadipour, M. Rahsepar, and H. Hayatdavoudi, Fabrication and Characterisation of Functionally Graded Ni-P Coatings with Improved Wear and Corrosion Resistance, Surf. Eng., 2019, 35(10), p 883–890.

F. Huang, J. Kang, W. Yue et al., Corrosion Behavior of FeCrMoCBY Amorphous Coating Fabricated by High-Velocity Air Fuel Spraying, J. Therm. Spray Technol., 2019, 28(4), p 842–850.

J.R. Scully, A. Gebert, J.H. Payer et al., Corrosion and Related Mechanical Properties of Bulk Metallic Glasses, J. Mater. Res., 2007, 22(2), p 302–313.

M. Sowa, D. Łastowka, A.I. Kukharenko et al., Characterisation of Anodic Oxide Films on Zirconium Formed in Sulphuric acid: XPS and Corrosion Resistance Investigations, J. Solid State Electrochem., 2017, 21(1), p 203–210.

C.A.C. Souza, D.V. Ribeiro, and C.S. Kiminami, Corrosion Resistance of Fe-Cr-Based Amorphous Alloys: An Overview, J. Non-Cryst. Solids, 2016, 442, p 56–66.

Z.H. Chu, W.X. Deng, X.W. Zheng et al., Corrosion Mechanism of Plasma-Sprayed Fe-Based Amorphous Coatings with High Corrosion Resistance, J. Therm. Spray Technol., 2020, 29(5), p 1111–1118.

R.Q. Guo, C. Zhang, Q. Chen et al., Study of Structure and Corrosion Resistance of Fe-Based Amorphous Coatings Prepared by HVAF and HVOF, Corros. Sci., 2011, 53(7), p 2351–2356.

A. Kumar, S.K. Nayak, P. Bijalwan et al., Optimization of Mechanical and Corrosion Properties of Plasma Sprayed Low-Chromium Containing Fe-Based Amorphous/Nanocrystalline Composite Coating, Surf. Coat. Technol., 2019, 370, p 255–268.

P.K. Katiyar, P.K. Behera, S. Misra et al., Comparative Corrosion Behavior of Five Different Microstructures of Rebar Steels in Simulated Concrete Pore Solution with and Without Chloride Addition, J. Mater. Eng. Perform., 2019, 28(10), p 6275–6286.

J. Wu, J.P. Cui, Q.J. Zheng et al., Insight into the Corrosion Evolution of Fe-based Amorphous Coatings Under wet-dry cyclic Conditions, Electrochim. Acta, 2019, 319, p 966–980.

C. Liu, Q. Bi, A. Matthews et al., EIS Comparison on Corrosion Performance of PVD TiN and CrN Coated Mild Steel in 0.5 N NaCl Aqueous Solution, Corrosion Sci., 2001, 43(10), p 1953–1961.

M. Isakhani-Zakaria, S.R. Allahkaram, and H.A. Ramezani-Varzaneh, Evaluation of Corrosion Behaviour of Pb-Co3O4 Electrodeposited Coating Using EIS Method, Corrosion Sci., 2019, 157, p 472–480.

P. Bijalwan, C. Singh, A. Kumar et al., Corrosion Behaviour of Plasma Sprayed Fe Based Metallic Glass (Fe73Cr2Si11B11C3 (at%)) coatings in 3.5% Coatings NaCl Solution, J. Non-Crystal. Solids, 2021, 567(4), p 120913.

M. Sun, S.Q. Shi, and B. Huang, Blue Energy Case Study and Analysis: Attack of Chloride Ions on Chromia Passive Film on Metallic Electrode of Nanogenerator, Nano Energy, 2019, 62, p 103–110.

K. Hashimoto, K. Osada, T. Masumoto et al., Characteristics of Passivity of Extremely Corrosion-Resistant Amorphous Iron Alloys, Corros. Sci., 1976, 16, p 71–76.

Acknowledgments

This work was supported by the (National Natural Science Foundation of China) under Grant (number 51579087); the (Fundamental Research Funds for the Central Universities) under (number B200205029).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Wu, Y., Hong, S. et al. Long-Term Electrochemical Behavior of an Arc-Sprayed FeCrBCSiNbMoNi Amorphous Coating for Rebars. J. of Materi Eng and Perform 32, 1160–1168 (2023). https://doi.org/10.1007/s11665-022-07150-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07150-3