Abstract

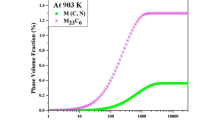

Custom 450 precipitation-hardenable martensitic stainless steel was solutionized and aged to achieve the best possible combination of hardness and impact toughness for cryogenic application. As-received material was solution-treated at 1040 °C followed by aging at 565 °C for different holding times, 2-16 h. On aging, the austenite phase is reverted by the memory-effect phenomenon, and its phase fraction was found to increase linearly with aging time. Austenite reversion (\(\gamma\)) occurred with acicular morphology at lath, sub-block, and block boundaries and globular morphology at the packet and prior austenite boundary. It was observed that acicular morphology of reverted-\(\gamma\) converted to globular with the aging time, and it was found to influence the hardness, and Charpy V-notch (CVN) impact toughness significantly influences. On the aging treatment of 2 h, the hardness was maximum, and toughness was least because of the possible precipitation effect. However, an enormous increase in toughness was observed for 4 h of aging with a small drop in hardness. A higher toughness is due to the presence of well-developed continuous reverted acicular-\(\gamma\). On aging beyond 4 h, the hardness increases, causing a decrease in the toughness to a similar level as solution-treated samples. Moreover, acicular austenite-\(\gamma\) thickness and globular-\(\gamma\) fraction increases with aging beyond 4 h, which may have accelerated the crack propagation. The dislocation density determined by the modified Williamson–Hall and modified Warren–Averbach method also increased on aging beyond 4 h, which may have attributed to higher hardness. The irregular trend in mechanical properties with aging time is due to the competition effect between the precipitation, phase transformation, austenite morphology, and recovery process with the aging time. Thus, careful aging for 4 h results in the best combination of hardness and toughness in Custom 450 stainless steel.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

J.E. Bridge and G.N. Maniar, Effect of Reverted Austenite on the Mechanical Properties and Toughness of a High Strength Maraging Stainless Steel Custom 450®, in: Metallogr. as a Qual. Control Tool, (Boston, MA), Springer, 1980, p 279–295. doi: https://doi.org/10.1007/978-1-4613-3090-5_13.

V. Govindaraj, P. Hodgson, R. P Singh, and H. Beladi, Precipitation Reactions in 12Cr–3Ni–3Mn–3Cu–0.15Nb Steel, Mater. Sci. Eng. A., 2021, 808, p 140909. doi: https://doi.org/10.1016/j.msea.2021.140909.

K.H. Lo, C.H. Shek and J.K.L. Lai, Recent Developments in Stainless Steels, Mater. Sci. Eng. R Reports., 2009, 65, p 39–104. https://doi.org/10.1016/j.mser.2009.03.001

H.J. Rack and D. Kalish, The Strength, Fracture Toughness, and Low Cycle Fatigue Behavior of 17–4 PH Stainless Steel, Metall. Trans., 1974, 5, p 1595–1605. https://doi.org/10.1007/BF02646331

U.K. Viswanathan, S. Banerjee and R. Krishnan, Effects of Aging on the Microstructure of 17–4 PH Stainless Steel, Mater. Sci. Eng. A., 1988, 104, p 181–189. https://doi.org/10.1016/0025-5416(88)90420-X

C.N. Hsiao, C.S. Chiou and J.R. Yang, Aging Reactions in a 17–4 PH Stainless Steel, Mater. Chem. Phys., 2002, 74, p 134–142. https://doi.org/10.1016/S0254-0584(01)00460-6

V. A. Kumar, M.K. Karthikeyan, R.K. Gupta, F. Gino Prakash, and P. Ram Kumar, Aging Behavior in 15-5 PH Precipitation Hardening Martensitic Stainless Steel, Mater. Sci. Forum., 2012, 710, p 483–488. doi:https://doi.org/10.4028/www.scientific.net/MSF.710.483.

Y.U. Heo, Y.K. Kim, J.S. Kim and J.K. Kim, Phase Transformation of Cu Precipitates from bcc to fcc in Fe–3Si–2Cu Alloy, Acta Mater., 2013, 61, p 519–528. https://doi.org/10.1016/j.actamat.2012.09.068

H.R. Habibi-Bajguirani and M.L. Jenkins, High-Resolution Electron Microscopy Analysis of the Structure of Copper Precipitates in a Martensitic Stainless Steel of Type PH 15–5, Philos. Mag. Lett., 1996, 73, p 155–162. https://doi.org/10.1080/095008396180786

Z. Wang, H. Li, Q. Shen, W. Liu and Z. Wang, Nano-Precipitates Evolution and Their Effects on Mechanical Properties of 17–4 Precipitation-Hardening Stainless Steel, Acta Mater., 2018, 156, p 158–171. https://doi.org/10.1016/j.actamat.2018.06.031

X. Peng, X. Zhou, X. Hua, Z. Wei and H. Liu, Effect of Aging on Hardening Behavior of 15–5 PH Stainless Steel, J. Iron Steel Res. Int., 2015, 22, p 607–614. https://doi.org/10.1016/S1006-706X(15)30047-9

M. Aghaie-Khafri, S.H. Mousavi Anijdan, and M. Amirkamali, Microstructural Evolution Under Ausforming and Aging Conditions in 17-4 PH Stainless Steel, Mater. Res. Express., 2019, 6, p 106532. doi:https://doi.org/10.1088/2053-1591/ab37e1.

L. Couturier, F. De Geuser, M. Descoins and A. Deschamps, Evolution of the Microstructure of a 15–5PH Martensitic Stainless Steel During Precipitation Hardening Heat Treatment, Mater. Des., 2016, 107, p 416–425. https://doi.org/10.1016/j.matdes.2016.06.068

C.A. Pampillo and H.W. Paxton, The Effect of Reverted Austenite on the Mechanical Properties and Toughness of 12 Ni and 18 Ni (200) Maraging Steels, Metall. Mater. Trans. B., 1972, 3, p 2895–2903. https://doi.org/10.1007/BF02652858

J. Han, A.K. da Silva, D. Ponge, D. Raabe, S.M. Lee, Y.K. Lee, S.I. Lee and B. Hwang, The Effects of Prior Austenite Grain Boundaries and Microstructural Morphology on the Impact Toughness of Intercritically Annealed Medium Mn Steel, Acta Mater., 2017, 122, p 199–206. https://doi.org/10.1016/j.actamat.2016.09.048

D. Raabe, S. Sandlöbes, J. Millán, D. Ponge, H. Assadi, M. Herbig and P.P. Choi, Segregation Engineering Enables Nanoscale Martensite to Austenite Phase Transformation at Grain Boundaries: a Pathway to Ductile Martensite, Acta Mater., 2013, 61, p 6132–6152. https://doi.org/10.1016/j.actamat.2013.06.055

M.R. Plichta and H.I. Aaronson, Influence of Alloying Elements Upon the Morphology of Austenite formed from Martensite in Fe-C-X Alloys, Metall. Trans., 1974, 5, p 2611–2613. https://doi.org/10.1007/BF02643888

N. Nakada, T. Tsuchiyama, S. Takaki and N. Miyano, Temperature Dependence of Austenite Nucleation Behavior from Lath Martensite, ISIJ Int., 2011, 51, p 299–304. https://doi.org/10.2355/isijinternational.51.299

X. Zhang, G. Miyamoto, Y. Toji, S. Nambu, T. Koseki, and T. Furuhara, Orientation of Austenite Reverted from Martensite in Fe-2Mn-1.5Si-0.3C Alloy, Acta Mater., 2018, 144, p 601–612. doi:https://doi.org/10.1016/j.actamat.2017.11.003.

K. Li, L. Wei, B. Yu, and R.D.K. Misra, Reverted Austenite with Distinct Characteristics in a New Cobalt-Free Low Lattice Misfit Precipitate-Bearing 19Ni3Mo1.5Ti Maraging Steel, Mater. Lett., 2019, 257, p 126692. doi:https://doi.org/10.1016/j.matlet.2019.126692.

X. Zhang, G. Shen, and C. Li, J. Gu, Phase-Field Simulation of Austenite Reversion in a Fe-9.6Ni-7.1Mn (at.%) Martensitic Steel Governed by a Coupled Diffusional/Displacive Mechanism, Mater. Des., 2020, 188, p 108426. doi:https://doi.org/10.1016/j.matdes.2019.108426.

J. Han and Y.-K. Lee, The Effects of the Heating Rate on the Reverse Transformation Mechanism and the Phase Stability of Reverted Austenite in Medium Mn Steels, Acta Mater., 2014, 67, p 354–361. https://doi.org/10.1016/j.actamat.2013.12.038

K. Li, J. Shan, C. Wang and Z. Tian, Influence of Aging Temperature on Strength and Toughness of Laser-Welded T-250 Maraging Steel Joint, Mater. Sci. Eng. A., 2016, 669, p 58–65. https://doi.org/10.1016/j.msea.2016.05.043

K. Tomimura, S. Takaki, and Y. Tokunaga, Reversion Mechanism from Deformation Induced Martensite to Austenite in Metastable Austenitic Stainless Steels., ISIJ Int., 1991, 31, p 1431–1437. doi:https://doi.org/10.2355/isijinternational.31.1431.

K. Tomimura, S. Takaki, S. Tanimoto, and Y. Tokunaga, Optimal Chemical Composition in Fe-Cr-Ni Alloys for Ultra Grain Refining by Reversion from Deformation Induced Martensite., ISIJ Int., 1991, 31, p 721–727. doi: https://doi.org/10.2355/isijinternational.31.721.

S.T. Kimmins and D.J. Gooch, Austenite Memory Effect in 1 Cr–1 Mo–0·75V(Ti, B) Steel, Met. Sci., 1983, 17, p 519–532. https://doi.org/10.1179/030634583790420484

H. Shirazi, G. Miyamoto, S. Hossein Nedjad, T. Chiba, M. Nili Ahmadabadi, and T. Furuhara, Microstructure Evolution During Austenite Reversion in Fe-Ni Martensitic Alloys, Acta Mater., 2018, 144, p 269–280. doi:https://doi.org/10.1016/j.actamat.2017.10.068.

S. Morito, H. Tanaka, R. Konishi, T. Furuhara and T. Maki, The Morphology and Crystallography of Lath Martensite in Fe-C alloys, Acta Mater., 2003, 51, p 1789–1799. https://doi.org/10.1016/S1359-6454(02)00577-3

N. Nakada, T. Tsuchiyama, S. Takaki and S. Hashizume, Variant Selection of Reversed Austenite in Lath martensite, ISIJ Int., 2007, 47, p 1527–1532. https://doi.org/10.2355/isijinternational.47.1527

M. Sato, S. Matsumoto, G. Miyamoto, and T. Furuhara, Microstructure of Reverted Austenite in Fe-0.3 N martensite, Scr. Mater., 2018, 156, p 85–89.

S. Mahadevan, R. Manojkumar, T. Jayakumar, C.R. Das and B.P.C. Rao, Precipitation-Induced Changes in Microstrain and Its Relation with Hardness and Tempering Parameter in 17–4 PH Stainless Steel, Metall. Mater. Trans. A., 2016, 47, p 3109–3118. https://doi.org/10.1007/s11661-016-3440-8

C. F. Jatczak, J. A. Larson, and S. W Shin, Retained Austenite and its Measurements by x-ray Diffraction. Warrendale, Pa, 1980

Astm, Standard Practice for X-Ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation 1, Astm. 03, 2009, 1–7. doi:https://doi.org/10.1520/E0975-13.necessary.

B.D. Cullity, Elements of x-ray diffraction, 2nd ed., Addison-Wesley Publishing Company Inc, 1957. doi:https://doi.org/10.1021/ed034pA178.

E. Prince, International tables for crystallography, 2016.

X. Li and Z. Yin, Reverted Austenite During Aging in 18Ni(350) Maraging Steel, Mater. Lett., 1995, 24, p 239–242. https://doi.org/10.1016/0167-577X(95)00109-3

D. Brandl, M. Lukas, M. Stockinger, S. Ploberger and G. Ressel, Evidence of Austenite Memory in PH 15–5 and Assessment of its Formation Mechanism, Mater. Des., 2019, 176, 107841. https://doi.org/10.1016/j.matdes.2019.107841

M. Manokaran, A.S. Kashinath, J.S. Jha, S.P. Toppo and R. Singh, Influence of Tempering in Different Melting Routes on Toughness Behavior of AISI 4340 Steel, J. Mater. Eng. Perform., 2020, 29, p 6748–6760. https://doi.org/10.1007/s11665-020-05164-3

H. Mirzadeh and A. Najafizadeh, Aging Kinetics of 17–4 PH Stainless Steel, Mater. Chem. Phys., 2009, 116, p 119–124. https://doi.org/10.1016/j.matchemphys.2009.02.049

S. Isogawa, H. Yoshida, Y. Hosoi, and Y. Tozawa, Improvement of the forgability of 17-4 precipitation hardening stainless steel by ausforming, 1998, 74, p 298–306. doi.org/https://doi.org/10.1016/S0924-0136(97)00286-0

H. Nakagawa and T. Miyazaki, Effect of Retained Austenite on the Microstructure and Mechanical Properties of Martensitic Precipitation Hardening Stainless Steel, J. Mater. Sci., 1999, 34, p 3901–3908. https://doi.org/10.1023/A:1004626907367

P. Li, Q. Cai, B. Wei and X. Zhang, Effect of Aging Temperature on Erosion-Corrosion Behavior of 17–4PH Stainless Steels in Dilute Sulphuric Acid Slurry, J. Iron Steel Res. Int., 2006, 13, p 73–78. https://doi.org/10.1016/S1006-706X(06)60099-X

J. Wang, H. Zou, C. Li, R. Zuo, S. Qiu, and B. Shen, Relationship of Microstructure Transformation and Hardening Behavior of Type 17-4 PH Stainless Steel, J. Univ. Sci. Technol. Beijing, Miner. Metall. Mater., 2006, 13, p 235–239. doi:https://doi.org/10.1016/S1005-8850(06)60050-9.

A.R. Stokes and A.J.C. Wilson, A Method of Calculating the Integral Breadths of Debye-SCHERRER Lines: Generalization to Non-Cubic Crystals, Math. Proc. Cambridge Philos. Soc., 1944, 40, p 197–198. https://doi.org/10.1017/S0305004100018314

E.J. Mittemeijer and U. Welzel, The “State of the Art” of the Diffraction Analysis of Crystallite Size and Lattice Strain, Zeitschrift Für Krist., 2008, 223, p 552–560. https://doi.org/10.1524/zkri.2008.1213

G.K. Williamson and W.H. Hall, X-ray line broadening from filed aluminium and wolfram, Acta Metall., 1953, 1, p 22–31. https://doi.org/10.1016/0001-6160(53)90006-6

B.R. Rehani, P.B. Joshi, K.N. Lad and A. Pratap, Crystallite Size Estimation of Elemental and Composite Silver Nano-Powders Using XRD Principles, Indian J. Pure Appl. Phys., 2006, 44, p 157–161.

S. Takebayashi, T. Kunieda, N. Yoshinaga, K. Ushioda and S. Ogata, Comparison of the Dislocation Density in Martensitic Steels Evaluated by Some X-ray Diffraction Methods, ISIJ Int., 2010, 50, p 875–882. https://doi.org/10.2355/isijinternational.50.875

Z. Cong and Y. Murata, Dislocation Density of Lath Martensite in 10Cr-5W Heat-Resistant Steels, Mater. Trans., 2011, 52, p 2151–2154. https://doi.org/10.2320/matertrans.M2011201

T. Ungár and A. Borbély, The Effect of Dislocation Contrast on x-ray Line Broadening: A New Approach to Line Profile Analysis, Appl. Phys. Lett., 1996, 69, p 3173–3175. https://doi.org/10.1063/1.117951

T. Ungár, I. Dragomir, Á. Révész and A. Borbély, The Contrast Factors of Dislocations in Cubic Crystals: The Dislocation Model of Strain Anisotropy in Practice, J. Appl. Crystallogr., 1999, 32, p 992–1002. https://doi.org/10.1107/S0021889899009334

T. Ungár and G. Tichy, The Effect of Dislocation Contrast on X-Ray Line Profiles in Untextured Polycrystals, Phys. Status Solidi., 1999, 171, p 425–434. https://doi.org/10.1002/(SICI)1521-396X(199902)171:2%3c425::AID-PSSA425%3e3.0.CO;2-W

A. Borbély, J. Dragomir-Cernatescu, G. Ribárik and T. Ungár, Computer Program ANIZC for the Calculation of Diffraction Contrast Factors of Dislocations in Elastically Anisotropic Cubic, Hexagonal and Trigonal Crystals, J. Appl. Crystallogr., 2003, 36, p 160–162. https://doi.org/10.1107/S0021889802021581

S.A. Kim and W.L. Johnson, Elastic Constants and Internal Friction of Martensitic Steel, Ferritic-Pearlitic Steel, and α-Iron, Mater. Sci. Eng. A., 2007, 452, p 633–639.

N. Forouzanmehr, M. Nili-Ahmadabadi and M. Bönisch, The Analysis of Severely Deformed Pure Fe Structure Aided by X-ray Diffraction Profile, Phys. Met. Metallogr., 2016, 117, p 624–633. https://doi.org/10.1134/S0031918X16060077

M. Kumagai, M. Imafuku and S. Ohya, Microstructural Features of Cold-Rolled Carbon Steel Evaluated by X-ray Diffraction Line Profile Analysis and Their Correlation with Mechanical Properties, ISIJ Int., 2014, 54, p 206–211. https://doi.org/10.2355/isijinternational.54.206

B.E. Warren, X-ray Studies of Deformed Metals, Prog. Met. Phys., 1959, 8, p 147–202. https://doi.org/10.1016/0502-8205(59)90015-2

Z. Arechabaleta, P. van Liempt and J. Sietsma, Quantification of Dislocation Structures from Anelastic Deformation Behaviour, Acta Mater., 2016, 115, p 314–323.

S. Sugiyama, T. Ogawa, L. He, Z. Wang and Y. Adachi, Quantitative Analysis of the Recovery Process in Pure Iron Using X-ray Diffraction Line Profile Analysis, Materials (Basel), 2021, 14, p 895. https://doi.org/10.3390/ma14040895

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that there is no conflict of interest

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bhavsar, V., Patil, N., Pawar, V. et al. Effect of Aging Treatment on Toughness and Hardness Behavior in Custom 450 PH Steel. J. of Materi Eng and Perform 31, 4242–4256 (2022). https://doi.org/10.1007/s11665-021-06519-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06519-0