Abstract

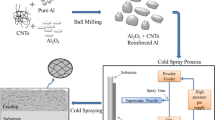

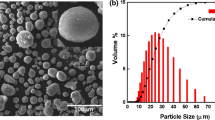

Modification of the surface is an effective approach for increasing the corrosion resistance of Mg alloys without influencing their bulk properties. Among numerous surface modification techniques, aluminizing is a low-cost and effective approach that is applied on many alloys for improved resistance to wear and corrosion. Based on the previous research, the enhancement by aluminizing can be further increased by the addition of rare-earth elements such as Y. In the current work, the effect of the addition of yttrium to the aluminizing mixture on the corrosion and tribological behavior of Mg-3%Al alloy was studied. Ball-on-disk tribometer and electrochemical testing apparatus were used to test wear and corrosion behavior and scanning electron microscopy was utilized to study the microstructures and worn surfaces. The results demonstrated that the aluminizing process is beneficial to the resistance of the alloy to wear, corrosion, and corrosive wear. The addition of Y makes the benefits larger. By adding Y, the wear volume loss decreased from 5.6×107 to 3.5×107 μm3 and the corrosive wear volume loss decreased from 4.1×106 to 3.5×106 μm3. In addition, incorporating Y in the aluminizing mixture resulted in a decrease in corrosion current from 4.59×10-2 to 6.17×10-3 μA. The improved properties are mainly attributed to the improved passivation capability of the modified surface layer.

Similar content being viewed by others

References

Nouri M. The Effect of Yttrium on Wear, Corrosion and Corrosive Wear of Mg-Al Alloys. University of Alberta, 2017

G. Song and A. Atrens, Understanding Magnesium Corrosion—A Framework for Improved Alloy Performance, Adv. Eng. Mater., 2003, 5, p 837–58. https://doi.org/10.1002/adem.200310405

G. Song, Recent Progress in Corrosion and Protection of Magnesium Alloys, Adv. Eng. Mater., 2005, 7, p 563–86. https://doi.org/10.1002/adem.200500013

S. Jayasathyakawin, M. Ravichandran, N. Baskar, C.A. Chairman and R. Balasundaram, Mechanical Properties and Applications of Magnesium Alloy—Review, Mater. Today Proc., 2020, 27, p 909–13. https://doi.org/10.1016/j.matpr.2020.01.255

B. Stalin, M. Ravichandran, V. Mohanavel and L.P. Raj, Investigations into Microstructure and Mechanical Properties of Mg-5wt.% Cu-TiB2 Composites Produced via Powder Metallurgy Route, J. Min. Metall. Sect. B Metall., 2020, 56, p 99–108.

D. Zhang, F. Peng and X. Liu, Protection of Magnesium Alloys: From Physical Barrier Coating to Smart Self-Healing Coating, J. Alloys Compd., 2021, 853, p 157010. https://doi.org/10.1016/j.jallcom.2020.157010

J.E. Gray and B. Luan, Protective Coatings on Magnesium and its Alloys—A Critical Review, J. Alloys Compd., 2002, 336, p 88–113. https://doi.org/10.1016/S0925-8388(01)01899-0

D. Zhang, F. Peng and X. Liu, Protection of Magnesium Alloys: From Physical Barrier Coating to Smart Self-Healing Coating, J. Alloys Compd., 2021, 853, p 157010. https://doi.org/10.1016/j.jallcom.2020.157010

V.S. Saji, Review of Rare-Earth-Based Conversion Coatings for Magnesium and its Alloys, Integr. Med. Res., 2019, 8, p 5012–35. https://doi.org/10.1016/j.jmrt.2019.08.013

X. Zhou, Y. Huang, Z. Wei, Q. Chen and F. Gan, Improvement of Corrosion Resistance of AZ91D Magnesium Alloy by Holmium Addition, Corros. Sci., 2006, 48, p 4223–33. https://doi.org/10.1016/j.corsci.2006.03.017

W. Liu, F. Cao, L. Chang, Z. Zhang and J. Zhang, Effect of Rare Earth Element Ce and La on Corrosion Behavior of AM60 Magnesium Alloy, Corros. Sci., 2009, 51, p 1334–43. https://doi.org/10.1016/j.corsci.2009.03.018

Y. Fan, G. Wu and C. Zhai, Influence of Cerium on the Microstructure, Mechanical Properties and Corrosion Resistance of Magnesium Alloy, Mater. Sci. Eng. A, 2006, 433, p 208–15. https://doi.org/10.1016/j.msea.2006.06.109

M. Nouri, X. Sun and D.Y. Li, Beneficial Effects of Yttrium on the Performance of Mg–3%Al Alloy During Wear, Corrosion and Corrosive Wear, Tribol. Int., 2013, 67, p 154–63. https://doi.org/10.1016/j.triboint.2013.07.012

X. Sun, M. Nouri, Y. Wang and D.Y. Li, Corrosive Wear Resistance of Mg–Al–Zn Alloys with Alloyed Yttrium, Wear, 2013, 302, p 1624–32. https://doi.org/10.1016/j.wear.2013.01.013

S. Jian, Y. Tzeng, M. Ger, K. Chang, G. Shi and W. Huang, The Study of Corrosion Behavior of Manganese-Based Conversion Coating on LZ91 Magnesium Alloy: Effect of Addition of Pyrophosphate and Cerium, Mater. Des., 2020, 192, p 108707. https://doi.org/10.1016/j.matdes.2020.108707

S.M. Banijamali, Y. Palizdar, S. Najafi, A. Sheikhani, M. Soltan Ali Nezhad and M.P. Valizadeh, Effect of Ce Addition on the Tribological Behavior of ZK60 Mg—Alloy, Met. Mater. Int., 2021, 27, p 2732–42. https://doi.org/10.1007/s12540-020-00832-4

M.S. Dargusch, Z. Shi, H. Zhu, A. Atrens and G.L. Song, Microstructure Modification and Corrosion Resistance Enhancement of Die-Cast Mg-Al-Re Alloy by Sr Alloying, J. Magnes. Alloy, 2021, 9, p 950–63. https://doi.org/10.1016/j.jma.2020.09.008

S. Siddique, A.A. Bernussi, S. Wilayat and M. Yasir, Surface & Coatings Technology Enhancing Structural Integrity, Corrosion Resistance and Wear Properties of Mg Alloy by Heat Treated Cold Sprayed Al Coating, Surf. Coat. Technol., 2020, 394, p 125882. https://doi.org/10.1016/j.surfcoat.2020.125882

M. Daroonparvar, M.U.F. Khan, Y. Saadeh, C.M. Kay, A.K. Kasar, P. Kumar et al., Modification of Surface Hardness, Wear Resistance and Corrosion Resistance of Cold Spray Al Coated AZ31B Mg Alloy using Cold Spray Double Layered Ta/Ti Coating in 35wt%NaCl Solution, Corros. Sci., 2020, 176, p 109029. https://doi.org/10.1016/j.corsci.2020.109029

A. Fattah-alhosseini, R. Chaharmahali and K. Babaei, Effect of Particles Addition to Solution of Plasma Electrolytic Oxidation ( PEO ) on the Properties of PEO Coatings Formed on Magnesium and its Alloys: A Review, J. Magnes. Alloy, 2020, 8, p 799–818. https://doi.org/10.1016/j.jma.2020.05.001

M. Molaei, K. Babaei and A. Fattah-alhosseini, Improving the Wear Resistance of Plasma Electrolytic Oxidation (PEO) Coatings Applied on Mg and its Alloys Under the Addition of Nano- and Micro-Sized Additives into the Electrolytes: A Review, J. Magnes. Alloy, 2021, 9, p 1164–86. https://doi.org/10.1016/j.jma.2020.11.016

R. Chaharmahali, A. Fattah-alhosseini, M. Nouri and K. Babaei, Applied Surface Science Advances Improving Surface Characteristics of PEO Coatings of Mg and its Alloys with Zirconia Nanoparticles: A Review, Appl. Surf. Sci. Adv., 2021, 6, p 100131. https://doi.org/10.1016/j.apsadv.2021.100131

N. Ghavidel, S.R. Allahkaram, R. Naderi, M. Barzegar and H. Bakhshandeh, Surface & Coatings Technology Corrosion and Wear Behavior of an Electroless Ni-P/Nano-SiC Coating on AZ31 Mg Alloy Obtained Through Environmentally-Friendly Conversion Coating, Surf. Coat. Technol., 2020, 382, p 125156. https://doi.org/10.1016/j.surfcoat.2019.125156

C. Zhong, F. Liu, Y. Wu, J. Le, L. Liu, M. He et al., Protective Diffusion Coatings on Magnesium Alloys: A Review of Recent Developments, J. Alloys Compd., 2012, 520, p 11–21. https://doi.org/10.1016/j.jallcom.2011.12.124

J. Kipkemoi and D. Tsipas, Rare-earth Modified Chromium-Aluminide Coatings Applied by Pack Cementation Method on Low-Alloy Steels, J. Mater. Sci., 1996, 31, p 6247–50.

J.B. Wen, W. Zhang, X.Y. Li, Q.A. Li, W. Jiu-ba, Z. Wei et al., The Influence of La on the Corrosion Resistance of Hot-Dip Aluminized Steel, Mater. Sci. Forum, 2005, 475–479, p 3851–4. https://doi.org/10.4028/www.scientific.net/MSF.475-479.3851

U TZ, Li DY. Beneficial effect of oxygen-active elements on the resistance of aluminide coatings to corrosive erosion and dry erosion 2000:57–63

H. Ahmadi and D. Li, Mechanical and Tribological Properties of Aluminide Coating Modified with Yttrium, Surf. Coat. Technol., 2002, 161, p 210–7. https://doi.org/10.1016/S0257-8972(02)00390-0

T. Zhang and D.Y. Li, Effects of Cerium on Dry Sand Erosion and Corrosive Erosion of Aluminide Coating on 1030 Steel, J. Mater. Sci. Lett., 2000, 9, p 429–32.

H. Ahmadi and D.Y. Li, Beneficial Effects of Yttrium on Mechanical Properties and High-Temperature Wear Behavior of Surface Aluminized 1045 Steel, Wear, 2003, 255, p 933–42. https://doi.org/10.1016/S0043-1648(03)00056-5

U TZ, Luo Y, Li DY. Erosion behavior of aluminide coating modified with yttrium addition under different erosion conditions 2000:102–9

X. Xu, Y. Liu, V. Tabie, S. Yang, C. Cai, Y. Xiao et al., Effect of La2O3 on Resistance to High-Temperature Oxidation and Corrosion of Aluminized and Aluminum-Chrome Coating, Mater. Res. Express, 2019, 6, p 1265b7.

J. Hirmke, M.-X.X. Zhang and D.H.H. StJohn, Surface Alloying of AZ91E Alloy by Al-Zn Packed Powder Diffusion Coating, Surf. Coat. Technol., 2011, 206, p 425–33. https://doi.org/10.1016/j.surfcoat.2011.07.050

R. Mola, Fabrication and Microstructural Characterization of Al/Zn-Enriched Layers on Pure Magnesium, Mater. Charact., 2013, 78, p 121–8. https://doi.org/10.1016/j.matchar.2013.02.004

Y.P. Ma, X.L. Li, L. Yang and X.P. He, Effect of Surface Diffusion Alloying on Erosion Wear Property of ZM5 Magnesium Alloy, Trans. Nonferrous Met. Soc. China English Ed., 2013, 23, p 323–8. https://doi.org/10.1016/S1003-6326(13)62464-4

R. Mola and K. Jagielska-Wiaderek, Formation of Al-Enriched Surface Layers Through Reaction at the Mg-Substrate/Al-Powder Interface, Surf. Interface Anal., 2014, 46, p 577–80. https://doi.org/10.1002/sia.5579

F. Liu, X. Li, W. Liang, X. Zhao and Y. Zhang, Effect of Temperature on Microstructures and Properties of Aluminized Coating on Pure Magnesium, J. Alloys Compd., 2009, 478, p 579–85. https://doi.org/10.1016/j.jallcom.2008.11.093

F.J. Liu, Q.S. Meng and Z.S. Li, Microstructure and Properties of Alloying Coating on AZ31B Magnesium Alloy, Trans. Nonferrous Met. Soc. China English Ed., 2016, 26, p 2347–54. https://doi.org/10.1016/S1003-6326(16)64353-4

J. Hirmke, M.X. Zhang and D.H. St John, Influence of Chemical Composition of Mg Alloys on Surface Alloying by Diffusion Coating, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2012, 43, p 1621–8. https://doi.org/10.1007/s11661-011-1034-z

M. Nouri and D.Y. Li, Maximizing the Benefit of Aluminizing to AZ31 Alloy by Surface Nanocrystallization for Elevated Resistance to Wear and Corrosive Wear, Tribiol. Int., 2017, 111, p 211–9. https://doi.org/10.1016/j.triboint.2017.03.009

M.-X.X. Zhang, H. Huang, K. Spencer and Y.-N.N. Shi, Nanomechanics of Mg–Al Intermetallic Compounds, Surf. Coat. Technol., 2010, 204, p 2118–22. https://doi.org/10.1016/j.surfcoat.2009.11.031

ASM Alloy Phase Diagram Database. 2014 n.d. https://www.asminternational.org

A.J.W. Moore and W.J.M. Tegart, Relation Between Friction and Hardness, Proc. R Soc. A, 1952 https://doi.org/10.1098/rspa.1952.0234

N.M. Mikhin and K.S. Lyapin, Hardness Dependence of the Coefficient of Friction, Sov. Phys. J., 1970, 13, p 317–21.

T. Zhang and D. Li, Effect of Alloying Yttrium on Corrosion–Erosion Behavior of 27Cr Cast White Iron in Different Corrosive Slurries, Mater. Sci. Eng. A, 2002, 325, p 87–97. https://doi.org/10.1016/S0921-5093(01)01405-8

L. Li and D.Y. Li, A Computational Study on the Effect of Minor Yttrium on the Interfacial Adherence of Al Oxide Film to Aluminum Substrate, J. Phys. Condens. Matter., 2019 https://doi.org/10.1088/1361-648X/ab1864

M. Nouri, Z. Liu, D. Li, X. Yan, N. Tahreen and D. Chen, The Role of Minor Yttrium in Tailoring the Failure Resistance of Surface Oxide Film Formed on Mg Alloys, Thin Solid Films, 2016, 615, p 29–37. https://doi.org/10.1016/j.tsf.2016.06.045

G.L. Song and A. Atrens, Corrosion Mechanisms of Magnesium Alloys, Adv. Eng. Mater., 1999, 1, p 11–33. https://doi.org/10.1002/(SICI)1527-2648(199909)1:1%3c11::AID-ADEM11%3e3.0.CO;2-N

R. Zeng, J. Zhang, W.-J. Huang, W. Dietzel, K.U. Kainer, C. Blawert et al., Review of Studies on Corrosion of Magnesium Alloys, Trans. Nonferrous Met. Soc. China, 2006, 16, p s763-71.

G. Song and A. Atrens, Corrosion Mechanisms of Magnesium Alloys, Adv. Eng. Mater., 1999, 1, p 11–33. https://doi.org/10.1002/(SICI)1527-2648(199909)1:1%3c11::AID-ADEM11%3e3.3.CO;2-E

I. Radu and D.Y. Li, A Further Study of the Beneficial Effects of Yttrium on Oxide Scale Properties and High-Temperature Wear of Stellite 21, Tribol. Lett., 2008, 30, p 27–34. https://doi.org/10.1007/s11249-008-9308-3

L. Wang and D.Y. Li, Effects of Yttrium on Microstructure, Mechanical Properties and High-Temperature Wear Behavior of Cast Stellite 6 Alloy, Wear, 2003, 255, p 535–44. https://doi.org/10.1016/S0043-1648(03)00057-7

Acknowledgment

The authors are grateful for financial support from Auto21 and the Natural Science and Engineering Research Council of Canada.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nouri, M., Li, D.Y. The Yttrium-Incorporated Aluminizing of Mg-3%Al Alloy for Improved Tribological and Corrosion Properties. J. of Materi Eng and Perform 31, 3218–3227 (2022). https://doi.org/10.1007/s11665-021-06479-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06479-5